TL;DR: Should I be concerned that the x-axis belt seems to lean a bit to one side of the motor gear on a brand new A1?

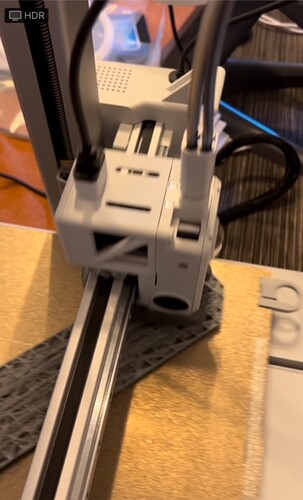

Belt leaning towards front when extruder is all the way left:

Belt centered when extruder is all the way right:

Belt now leaning to the left instead of right after trying to center it:

Long version: I just got an A1 with AMS Lite, adding to the A1 Mini I already had. Loving them both, but the A1 has made me a little nervous with some of the noises it’s been making. The prints have so far been fine, and I’ve found a few posts here and on reddit that mention there being strange noises but they didn’t affect print quality. That seems to be my case as well, prints have been fine so far, but I hadn’t noticed these noises with the Mini so they drew my attention.

Trying to do a little troubleshooting, I looked at the belts first. The y-axis belt seemed fine, no noises when I’d manually move it back and forth, and the belt itself was tracking right in the center of the gears on both ends. The x-axis belt didn’t seem to make any concerning noises either when I was moving it. However, that x belt, on the right/positive side where the motor is, it had been leaning to one side on the motor’s gear. When the extruder was all the way to the right/positive end, the belt would be centered, but then when the extruder was moved all the way to the left/negative end, the belt would be shifted a few mm towards the front of the printer.

I opened up the casing around the motor, and just nudged the belt over a bit, and then when I moved the extruder back and forth by hand, it seemed to stay centered. But then, when I restarted the print, the belt seemed to nudge itself over to the other side, towards the back of the printer. I can live with this if it’s not going to damage the belt prematurely or mess up prints, but I’d like to know if there’s something I could do to finesse it into staying centered. Maybe it’s all a non-issue and I should just stop worrying about it.

(I do believe the sound I was hearing was actually the nozzle colliding with the infill on this particular print. I’ve heard of that being a problem before with certain infill patterns. I typically use gyroid, but this was a model I grabbed from Makerworld and it used adaptive cubic, and I just didn’t bother to change it. I hadn’t noticed this issue with the Mini though, and that little guy’s nearing 500 hours of print time. Again, the prints have been coming out fine on the A1, it’s just that looking for a potential problem led me to finding a different potential problem. Also, I suspect this PLA’s gotten a little wet so I’m thinking it’s crackling a little bit, contributing to the confusing noises.)

PS - One suggestion I have for the printer controls: I had initially paused the print that was running in order to troubleshoot. When I was using the XYZ control menu to move the extruder and heat bed around, at one point I accidentally tapped the Home button. This caused the extruder to do it’s normal centering routine, and it crashed into the print. I believe it then recalibrated the bed height, and then printed spaghetti when I started the print back up. My suggestion is not allowing the home button to do anything if there is a print paused, or at least give a warning pop-up so you don’t do it by accident like I did.