Prooving? What are u talking about sir? The profiles i use on a regular basis suddenly turns on the exhaust fan for all asa and abs filaments. This warps these filaments as the chambertemp is baaaarely enough as is of 50c. All my prints warped off the bed.

Regarding the wear claim, the producer of the belt states operation temps uptil 60c under optimal contitions, optimal. This is far from that.

I suspect u print mainly pla and have little to no experience with high temp polymers, as is you do not understand the effect of a chamber from above mentioned filaments.

Why yours are different from mine could many factors including and not limited to zone, to country, to hardware revision.

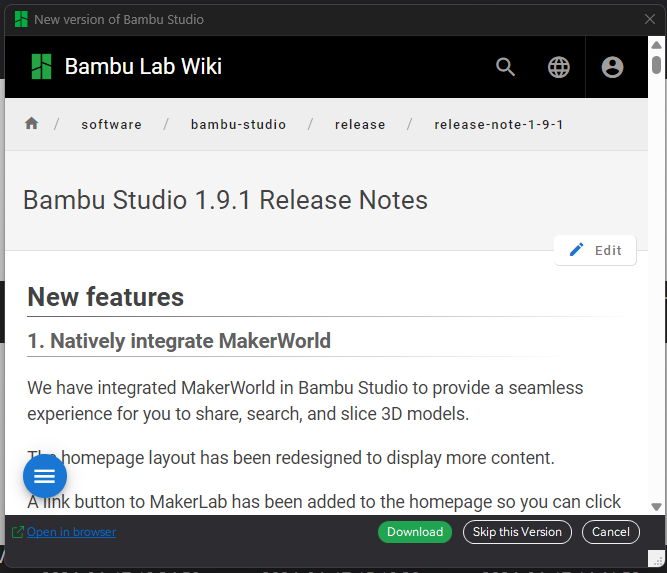

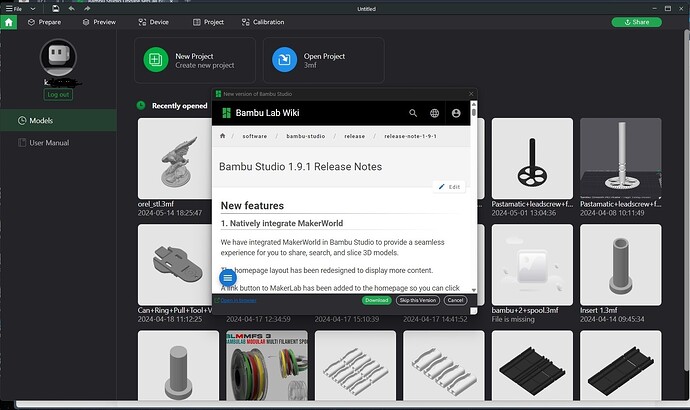

I can make screenshot to proove all pa,abs and asa profiles are now with 70% exhaust fan.

Which is one of two… either a huge blunder or a security measure.

If you ever did ht materials you would know that draft is your enemy. Are you suggesting i magically changed all the profiles of pa/abs/asa to 100% certainly loosen from the plate and warp?

And the file I made in visual studio as a profile for the asa filament i regularly print with and have several custom made profiles for. Which i then imported to BS, that got changed by BL to ruin four cosecutive prints costing me only time, filament and headache.

I dont know how you dont understand this.

Do check pa/asa/abs filament profiles on your own install and see that they turned on the exhaust for them.

For PLA exhaustfan is only needed if chamertemp exceeds jamtemp for the poorly heatinsulated extruder and its path, but when you have a chambertemp of 50c, for a duration of time i would accept the exhaust to keep the temp ±2c.

Any sooner or any higher speed than (pulling number out the air) say 50% would create a draft that would be detrimental to an pa/asa/abs print. Even catastrophic failure is possible since these materials love to warp at the slightest draft. The fan is quite powerful and creates at least in my x1c a hefty draft enough to warp corners on a 30x30x0.2 square. So i think 50% is more than generous an assuption on BLs behalf.

I have not bothered to edit the native profiles as i just use a few types of filament, i just turned it off from the slicer and that was that. Exported and safely out of BLs reach…

I umderstand you have little to no knowledge of personal rights in other countries let alone your own? To alter a persons data is considered an punishable offence in many countries…

Like i said… im not getting into that. And you did still didnt you? Sigh…

The whole point is that 70% exhaust is bad for those filaments and i did not change it… if you doht understand now i cant help u. And liking ur own posts is lame…