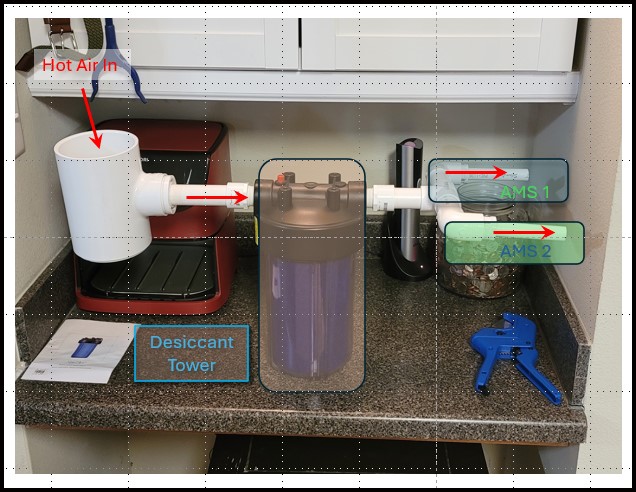

I’ve been chipping away at building a hot and DRY air purge for my two AMS connected to a P1S.

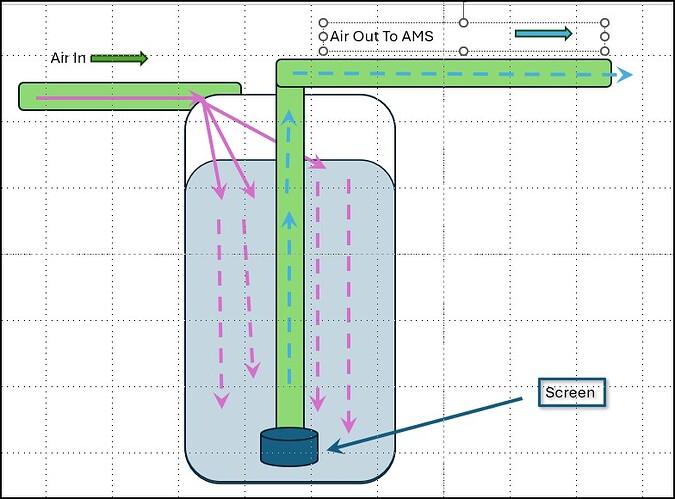

Here’s a sketch of where I am

What type/size of fan/pump are you planning on using to push air through your system?

That has been my biggest struggle.

I am going to try a hair blow dryer.

Tested a dehydrator heater/blower and nowhere near enough push to get it through the through the volume of desiccant.

Biggest concern is too much heat and melt something.

I have a 4’ piece of 4" PVC pipe that will go in bottom of 4" Tee so it will stand on it’s own.

Print a bushing whose OD is 4" to fit in Tee and whose ID will be same diameter as hair dryer nozzle.

Using a dehydrator or blow dryer, they have built in thermal protection I’m pretty sure. The heat aspect is the challenge. I can always get a baby compressor

The static pressure in your system is going to be the problem. The restriction due to the transition to small pipe size, the drier and the elbows all add up.

An axial fan such like one in a hair dryer will really struggle to produce any static pressure. By design it moves a lot of air with little restriction.

There are fans that can build much higher static pressure. A compressor on the other hand has the added benefit of adding heat to the air. How much air are you looking to use/exchange?

I think blowing hot air into the desiccant will be an issue. Temperature is important to drying filament and drying silica gel beads. Blowing hot air into the beads will keep them from absorbing as much water from the ambient as they normally could.

It would be much better to heat the air after the desiccant column. That way the desiccant can remove more water. It will work the way you diagram but not for as long or as well as if you dry the air before heating it.

Also, that kind of fixture you are using to hold the beads is usually intended to have a filter kind of thing in it that itself forces the air to move through the filter and not bypass it.

Unless you added tubing to force the air through the beads, it looks like the air would just bypass the bead column and flow across it. I’m guessing you have that detail covered but thought I mention just in case. The air has to flow through the beads for them to dry the air.

You’ve got to start somewhere. When it goes in service, it will work.

You can’t see it for the beads, but air enters the cannister and discharges into the beads at the top. To exit the cannister it has to go to bottom of cannister where it goes through a basket screen made to Have a grid slightly smaller than bead size.

Current smallest diameter pipe is 1 inch.

Forgot to mention but there is a full gallon of silica beads in vessel