I can imagine one more use case - combining more nozzle diameters 0.2 for details, 0.4/0.6/0.8 for the rest of the model.

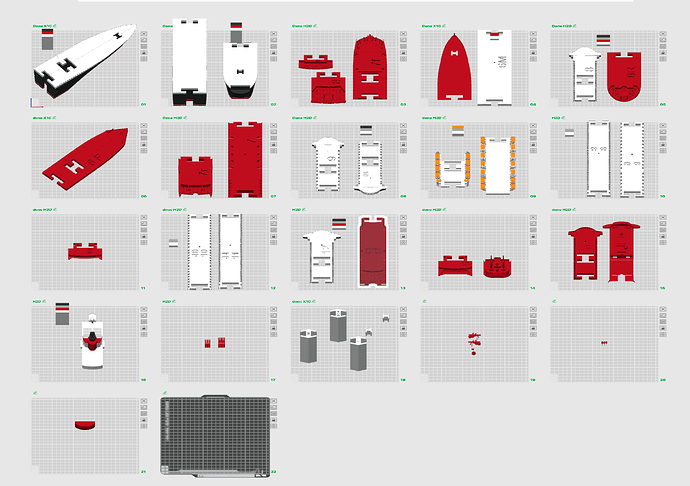

That’s definitely where I would use mixed nozzles for - for example in this print when I printed it at 50% scale I actually printed the parts labelled in red with dual 0.2 nozzles and the rest of the parts with dual 0.4.

The reason for the 0.2 was just a few tiny parts of the objects - like railings and stairs were too small to print at 0.4 - so I had to print a fairly large part at 0.2 to avoid too much splitting up of the model.

If I could mix 0.2 and 0.4 on those parts I think they would have printed 3 or 4 times as quick.

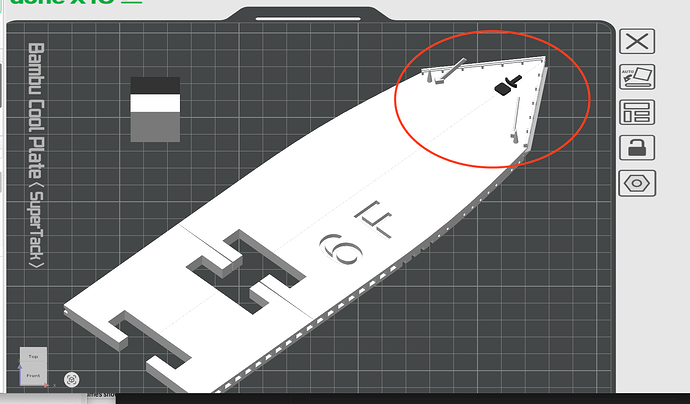

Example of candidate 0.2mm parts on plate 6

In this case probably 95% of the part would be able to be printed at 0.4 single colour, then just some 2 colour 0.2 for the last few layers - so only one extra nozzle switch - and at least 5x quicker print time.

The C in X1C stands for the carbon X guides. Nothing to do with the filaments that you can print with it.

Printing carbon filled filaments requires hardened steel (or harder) nozzles and extruder gears.

You guys are both right. The original X1 had steel rods, regular steel nozzle and extruder. The X1C upgraded that to carbon rods, hardened steel nozzles and extruder.

The X1 had carbon rods too ![]()