I’ve been exploring this topic since 2023 with mixed results - some excellent, some mediocre. My goal was the opposite of diffusion: I was trying to achieve optical clarity.

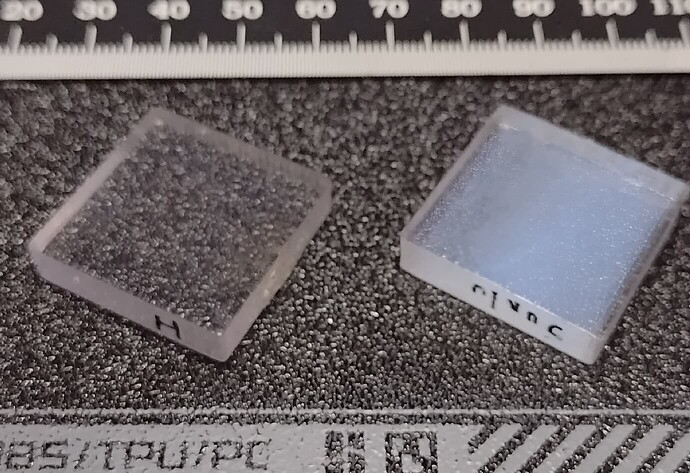

Here’s what I mean. The left-hand sample is what I was aiming for and ultimately achieved. The right-hand sample was an experiment that went wrong:

@ExtremeElementz started a great thread in 2023 that led me deep down the transparency rabbit hole:

That thread contains a lot of trial-and-error, including my failed attempts - many of which produced the kind of foggy, diffused look you’re actually targeting.

Based on that, here are some suggestions. First, unless your diffuser will be exposed to high heat, avoid transparent PLA - it’s barely transparent and not worth the trouble. PETG might be better, but note that the foggy sample above is Sunlu’s “transparent” PETG, which was anything but transparent.

To achieve optical clarity, I used @ExtremeElementz’s “icecube” profile. Here’s how it works - and how you can reverse the principles to promote diffusion:

-

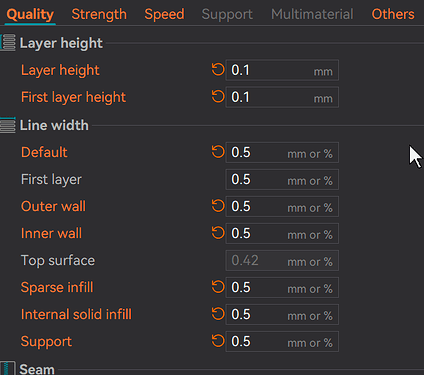

Line Width

Clarity requires oversized line width to eliminate air gaps. For diffusion, do the opposite: reduce line width to intentionally introduce inter-filament air gaps.

-

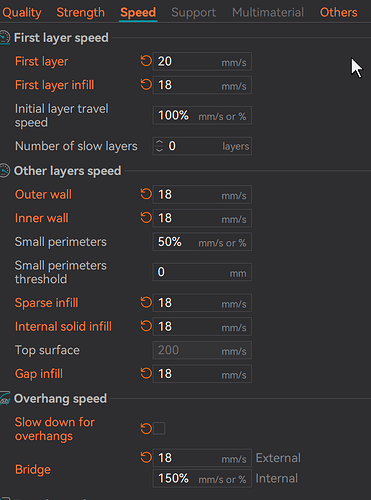

Print Speed

Clarity demands slow speeds. To create diffusion, increase speed. This introduces turbulence and creates more internal scattering surfaces.

-

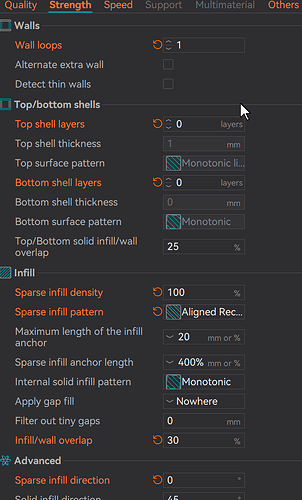

Surface Layers

I optimized for smooth surfaces. You’ll want the opposite - something less uniform and more chaotic.

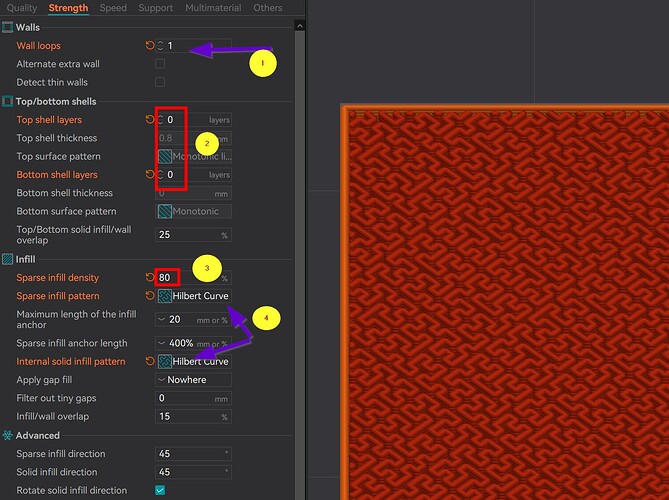

Here’s a test configuration I’d try for maximizing light diffusion (note: I haven’t tested this exact combo, but it’s informed by my failures achieving transparency):

- Walls: Set wall loops to 1 - prevents a solid outer rim from forming.

- Top/Bottom Layers: Set to 0 - ensures only the infill is visible.

- Infill %: Try values above 70% - promotes internal gaps and irregular paths for light.

- Infill Pattern: Start with Hilbert Curves - they create uniform but turbulent patterns. Lightning infill is also worth trying, though it may be too chaotic.

I just purchases some transparent PETG from CC3D during Prime Day that I haven’t gotten a chance to test yet. However, In the example above I can report that Sunlu transparent PETG was very foggy and has no right calling itself transparent, translucent maybe but not transparent. You could try that if you need temperature resistance and don’t want to use PLA.

Hope this helps steer your experimentation. Your goal may be the opposite of mine, but the process still overlaps in all the right (and wrong) ways.