I think you guys may find this interesting.

Reporting back regarding:

When I first received it, I had been waiting and had a need to print right away. Therefore, i dried it at 130C but only for 3 hours and 33 minutes. During that time it lost 1.16g of moisture.

However, it was noticeably more brittle than the Bambulab PPS-CF that I had previously printed. In fact, the filament broke two or three times during the print.

Nonetheless, I was able to complete the print successfully. Because brittleness might conceivably be the result of undesirably high moisture content in the filament, I resolved to dry it more thoroughly. Therefore, I dried it at 130C for 1 day 7 hours and 2 minutes, during which time it lost 8.04g. The filament looked fine, so, for good measure I increased the drying temperature to 140C for another 11 hours and 10 minutes, during which time it lost an additional 20.3g of moisture!

Plainly, that extra 10C in temperature made a huge improvement in terms of moisture yield.

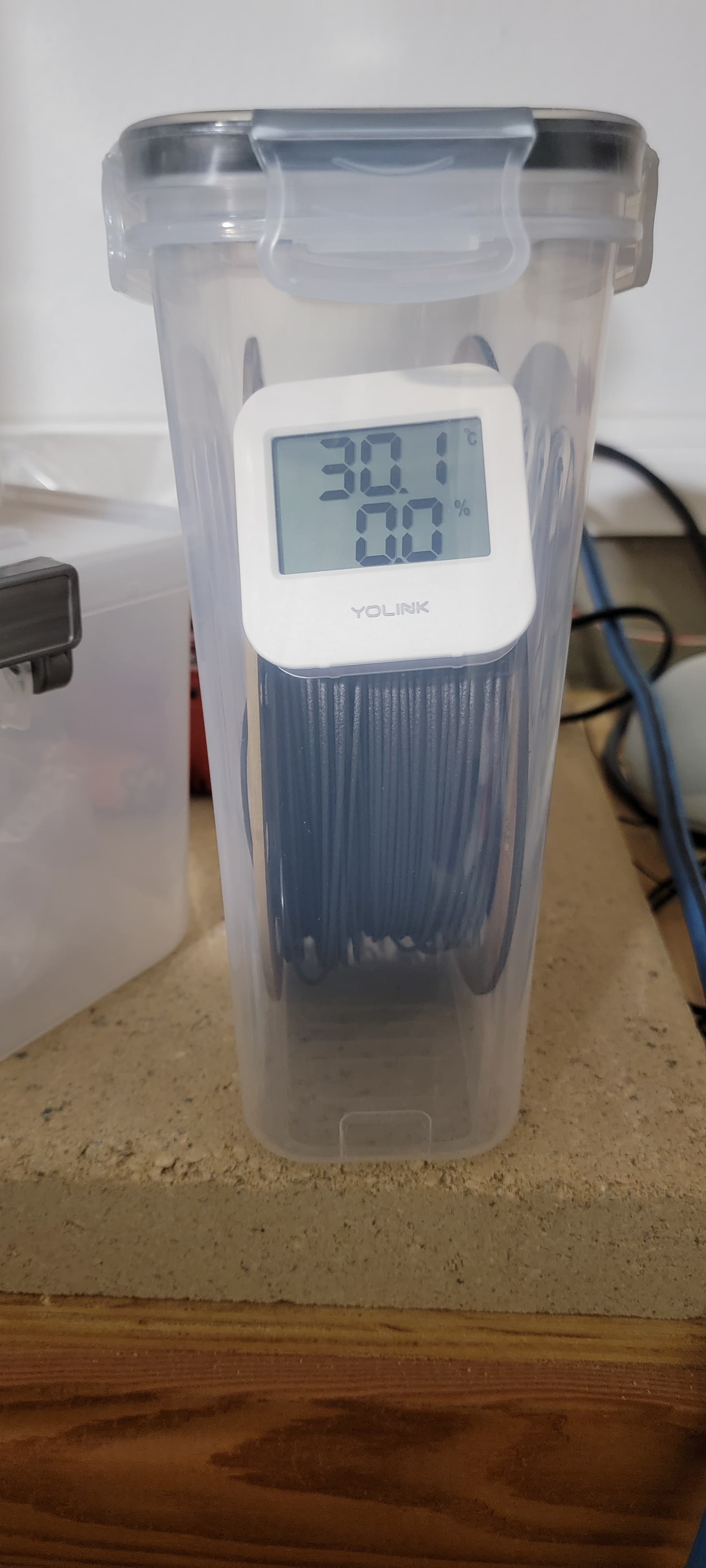

I was curious as to what its new relative humidity percentage might be, so I sealed it inside a plastic cereal box container without any desiccant, and its RH percentage now reads 0.0%, most likely because the cardboard spool it’s mounted on is now acting like a desiccant.

Most silica gel desiccant would have an equilibrium RH% greater than 0, so for now I haven’t added any, as doing so would merely transfer moisture from the gel desiccant into the spool and its filament. ![]()