While I am now intrigued by the PPS-CF discussion, I have been trying to find settings to use for PC-CF (IEMAI brand) and don’t know which Bambu profile to use as a starting point. Three questions: 1) Which profile should I use ? (I started with the Bambu ABS-GF, because someone had posted that it smelled like it was mixed with ABS, but now think I should modify the PC profile and just slow it down) 2) What adjustments should be made to the profile? 3) Why is there no mention of PC-CF being used on Bambu ?(does everyone use PPS-CF?) Any help would be greatly appreciated - my part print time is about 20 hours, so it makes me sad when they fail.

I would start with PC profile and go from there. Try it as is and if there are defects adjust the profile, PC and PC-CF should be very similar in temp and speeds. I would however adjust the chamber temp to the max 65c to reduce warping. PC is notorious for warping so when I need something sturdy and heat resistant I go to ABS-GF, Nylon or PPS. I mainly use PC (non-CF) when I need something heat resistant and smooth, like poop slide for the H2D. Otherwise there are usually better filaments for the job. Thats why I guess you dont see too many people using PC-CF or many profiles for it. Prusa is the only company embracing PC-CF.

You should be able to look at the MSDS/TDS to find out if there is ABS in it. Any decent filament manufacturer should have one published. If they dont have one, I would stay away from that brand for engineering filaments.

Thanks for the feedback. I have printed a lot of PC-CF (on Prusa) and speeds have to be set slower (due to the CF particles - when it moves too fast, it tears out infill). I am using PC-CF because I need maximum rigidity, which all of the filament references and ChatGPT seem to agree is the best (max rigidity, no warping). I suspect I can use the PC profile and dial down the volumetric speed to get the results I need. And the only good PC-CF I have found so far is Prusa, and they are generally out of stock, so there seems to be Priline and IEMAI. And 3DXtech who are expensive and seem to think that putting 2kg on a 5kg spool is a good idea. Thanks again for your feedback - Hopefully I can switch to another filament soon, but I am currently sitting on a pile of PC-CF!

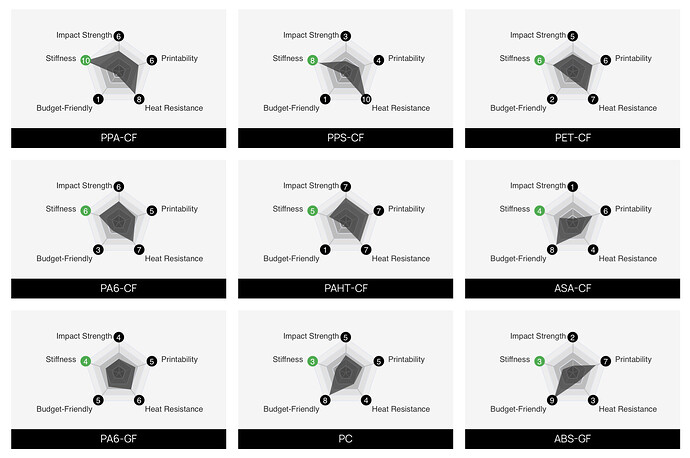

PA6-CF or PAHT-CF will be more stiff than PC. PET-CF, PPS-CF and PPA-CF being progressively more stiff than either of those.

Just curious as to why PPA-CF didn’t make your list. Also, which nylons?

I was surprised that in your spider diagrams, ABS-GF had only a stiffness of 3. Does that seem right?

Thanks for posting the diagrams - it looks like the PAA-CF is the one to beat. It’s a shame they didn’t include PC-CF, as I think it is considered more rigid with less warping than the nylon blends, but apparently not as good as the PPA-CF. Thanks again!

Yikes! Just saw the price of PPA-CF.

PPA is a Nylon so it was redundant to mention it. I usually use PAHT as its AMS compatible and when saturated with moisture from the environment (air) its stronger than PA6. PA6-CF is not AMS compatible and only stronger when dry, PA6-GF is AMS compatible but again its weaker.

Both Bambu PPA and PPS are on sale so a good time to grab some. You can also buy Siraya or other brand stuff on amazon for less than regular bambu prices. How much is PC-CF? Never purchased it before, much cheaper?

Also here is the new filament guide from bambu:

So some summery when printing PPS-CF:

- Set the fan to 0% in the filament profile under cooling.

- Use a brim 5mm or more?

- Set the Elephant foot compensation to 0 (under Quality for the object).

- Lower the speed.

- Use lower layer hight.

What did I miss (taking from memory only)?

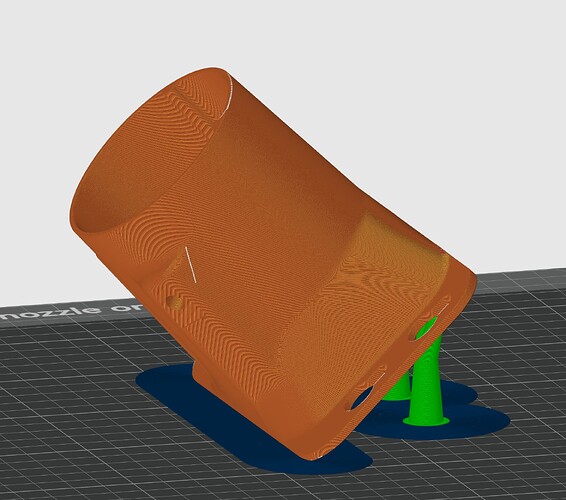

I was also thinking I would like to try to print models in 45 degree angle since it has given great results with other materials. But on the other hand usually you get more overhangs and a very small first layer.

Anyone that have tried this?

How are you doing it?

================

I was thinking of something like this picture.

Not sure this would good for this model but it would interesting to see what happens with the warping. It might be high risk of the whole part coming loose from the build plate?

I imagine with a CF filament you might be OK.

Or, if you’re doing it for more structural strength, why not simply increase number of walls? NeedItMakeIt says he uses 6 walls, 6 layers on topic and bottom, and 35% infill for his functional parts.

Of course, you could still do all that and still lean it at 45 degrees I suppose for even greater strength?

I saw him saying that to and when I saw it I thought that was a bit overkill but If You Need It Do It ![]()

I was more thinking about how it would affect the warping and seeing the strength as a good bonus.

Before when I tried it on PLA parts it was mostly for the strength on part with relatively thin walls and printed with so many walls that it became almost 100%.

I could imagine 45 degrees reducing warping on cases where there would otherwise be long straightaways at 0 degrees. Consider a flat board for instance.

This guy does give some interesting insight into how best to print at 45 degrees, as well as the strength advantages:

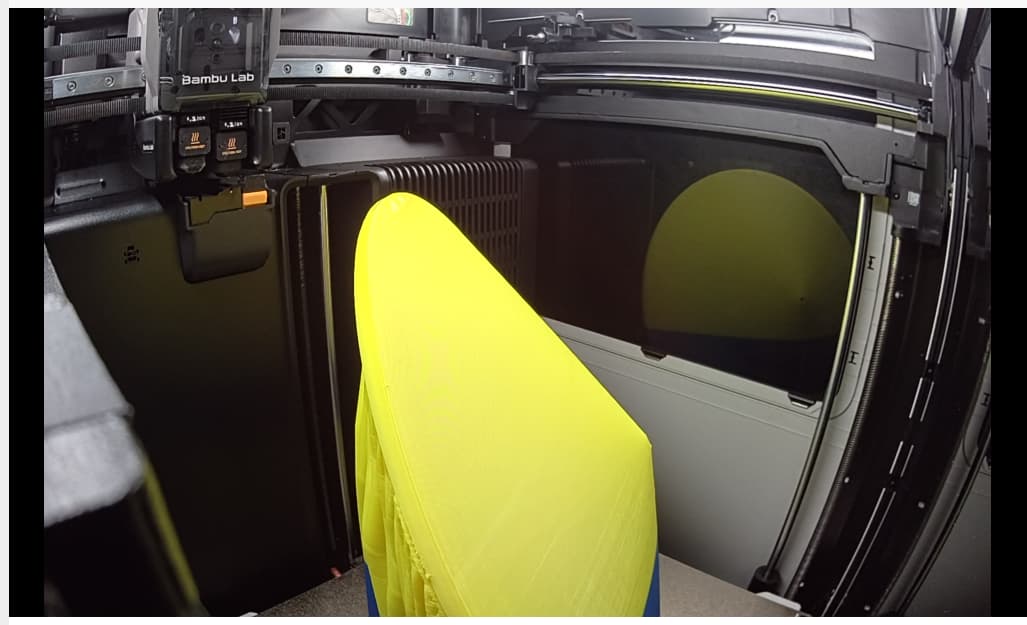

I suppose another advantage that no one ever seems to mention: you effectively increase the XY dimensions of your print, at least for those scenarios where the printed object is relatively flat (not a lot of z-height), which is probably 99% of my prints. You effectively increase your XY build space by up to an extra 41.4% in one direction or the other, which is significant. If you could engineer the supports for printing at 45 degrees in both X and Y, then you could get up to that amount in both X and Y. Although I’ve not seen anyone ever do that, with enough support you certainly could. ![]() The flatter the print model, the more you can cash in on this option.

The flatter the print model, the more you can cash in on this option.

Funny I think that is the video that got me testing with it and for the right print it works very well.

But in regards to warping and printing with CF I’m not sure if it will be better. I did a print with PLA-CF just a few days ago and that worked fine in 45 degree, but that material doesn’t warp anyways so I guess it doesn’t give any hints directly. If it wouldn’t that expensive I would test just to see how it work with PPS-CF.

@Pontus_BC I just now did the experiment, creating a huge saucer (roughly 14" in diameter after laying it flat) using a few spools of leftover HS-PETG by tilting it upward 45% in both X and Y, relying on just tree supports to keep it from tipping over, and I saw no warping at all. It may be a crude predictor, but given that result given its extreme size and without any CF, it seems unlikely we’d see any warping with PPS-CF with any tilting we might do with it.

Does that adequately answer your question, or is there more we’d need to test for you to feel confident ?

The test print itself isn’t really a saucer, but rather a bespoke hat I threw together in fusion360 for diverting rain water from dripping directly onto a propane tank, so it actually served a purpose and wasn’t just a huge waste of filament.

@NeverDie I don’t see a huge saucer as a waste of filament ![]()

It’s nice to see that you have good results with the tilted print. It gives me more of a feeling this can give some benefits when it comes to warping. But in the end I think I’ll just try it on the PPS-CF print when the time comes to the next PPS-CF print do be done, right now I don’t have any of those in the pipe.

Thank you for sharing.

I thought I would have to dedicate a nozzle just to pps-CF, because of jamming when subsequently printing with PLA. However, I found that if I crank up the temperature to 350C I can manually extrude the PLA through the nozzle to clean it out, and then all is good. I can then print PLA after all on the same nozzle that previously print PPS-CF.

Just sayin’. Wasn’t sure it would work, or whether the PLA would melt before it even got to the meltzone of the hotend, but it worked out OK.

Of course, it would be nice if the H2D could remember what was last printed in any given nozzle and do this for me, but the infrastructure for that just isn’t there yet.