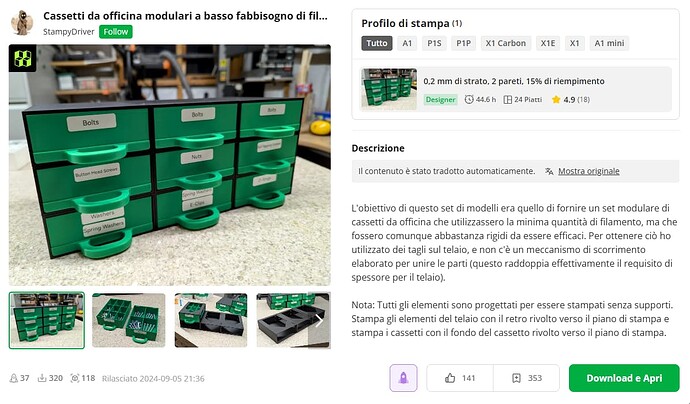

I find myself making a very banal print of a chest of drawers which gives me defects on the edge as in the photograph. I have little experience and I can’t understand what the problem is.

I use A1

Pla Bambu

I lowered the temperature to 215 and the print bed to 55 compared to those of the bamboo filament preset

The rest of the print is reasonably good. Could someone more knowledgeable tell me something. Thank you in advance

Looks like you had some warping despite the brim.

Did you dry your filament? Moisture is common even in fresh filament with curling/warping being an early indicator for worse issues.

Did you thoroughly clean your build plate (water + diswashing liquid (+ for the textured plate a clean, stiff brush)? Such a large surface should not really need a brim on a clean plate.

Is the room the printer is in particularly cool? Move it to a warmer room or crank up the heat. Warping is caused by temp differentials, so warmer environments are better.

PS: Do not lower the bed temp. That will reduce adhesion to the plate. Lowering the nozzle temp is a very last resort. It is usually better to try a few other things first (going slower, reducing layer height), but the basics from my prior post need to be covered before trying those.

Thank you for your response.

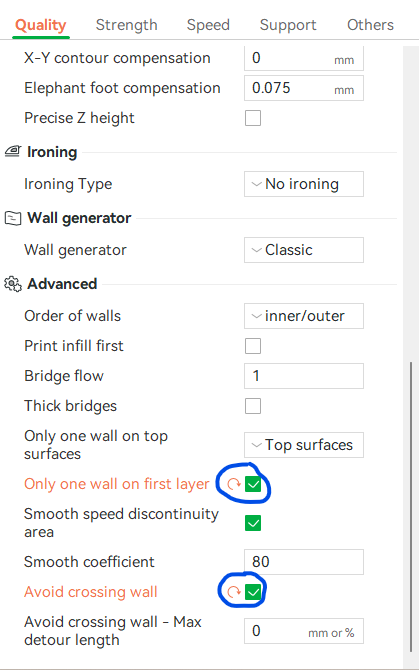

The filament was dried for 20 hours at 55°C and stored in a vacuum-sealed container. The print bed was cleaned with water and detergent (I did not use a brush). The room where the printer is located is cold, but I purchased a Chitu enclosure that fully encloses the printer, raising the internal temperature to a stable 24°C. The model was downloaded from Bambu’s website and uses the settings provided by the model’s creator, with only two modifications compared to the default ones.

I also tried to print a benchy boat and the result seems decent to me. In the evening I can post a photograph because I’m at work now.

I don’t understand much about it but I noticed that the defect occurs near the seam when the rectangle closes as if it depended on a deceleration.

In fact, at the handle the stitching occurs under the handle and the problem occurs before and after the height of the drawer handle and not at the height of the handle.

I’ll try decreasing the speed to see what effect it has on the print

I will also try to print a rectangular model designed by me to see if I have the same problem

PS: I don’t know if you can see it but there is also some hanging fluff