I’m saying that more from a quality standpoint with current steppers and absolutely see more to come from other aspects. As an owner of and a big fan of toolchangers I’m excited about Bondtech’s up and coming system but also feel much of the print quality issues people are experiencing on all printers are stepper related. I’ve not found a stepper yet that doesn’t give VFA’s at speeds under 120mm/s. I print a lot of PETG and it hates higher speeds and lower print speeds give the VFA’s. Stepperonline 2504’s give me the best results on my home built but PETG prints are still mediocre at lower speeds. Qidi and Orca added a “resonance avoidance” setting to their slicers to help avoid speeds that cause issues. The H2D not being compatible with Orca is the biggest drawback with the printer that I have.

Always wondered how this would work. Haven’t seen much results online yet… But from the discussions on Github and the pr created by Noisyfox, I doubt if it would really do anything beneficial for a printer with proper input shaper integration.

That’s quite interesting, I assume this is with a .4 nozzle, do you know if/how layer heights changes the speed zones that trigger PETG VFAs? And what temperature ranges?

Or maybe next we will see some system to print withoutsupports, with Air assist or something similar. Think CPAP but the air will hold the filament into place. Crazy i know, but that was also said in 2005 when someone thought it would be brilliant to say “you wouldnt download a car”

most corexy printer do the worst in 70-120mm/s range. VFA has nothing to do with layer height though. Unless you’re talking about layerheight being too high causing underextrusion, which then causing matte finish, which then is hiding the VFA slightly better.

It doesn’t help nearly as much as I hoped it would, ultimately I set my minimum print speed to 140 mm/s in cooling and bump up flow rate to minimize VFA’s.

If you ever hang out on the voron github, it will blow your mind. well over 1000mm/s and 40k accelerations.

Then go look at a VZBot….Problem for me is that PETG doesn’t like to print fast. PETG speeds on a Voron or any other printer that I’m aware of exhibit the same VFA’s. Due to lack of proper ventilation I’ve never played with ABS or ASA so not sure where the upper limit of speed and quality is.

Ewwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwwww. That is not good!

High speed asa is the fastest. Once you go beyond a certain point on your build, resolidifying becomes harder than melting. For prebuilt hobby printers, pla is your best bet still because they are so limited on hotend power. Remove that limitation and cooling becomes more important. Stuff like cpap come into play. Its like rc cars or even gaming pc’s…kits or self sourced will always beat prebuilt. With money and skill of the builder being the limiting factors

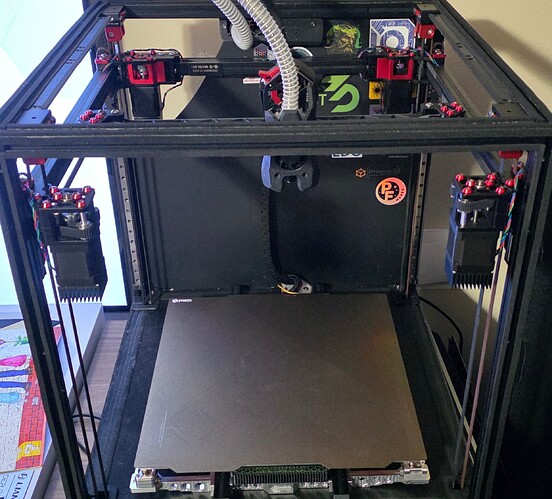

This is my other printer… It exhibits the same VFA’s at similar speeds as the HD2 does. It prints slightly slower than the H2D and is much much louder and it’s not nearly as hit print and walk away as the H2D has been…

Try ldo super power 2804AH(2504 if you want to go 48 volt) steppers and TMC2240 drivers. Awd will make a huge difference too. Also going up to 3030.

My Voron

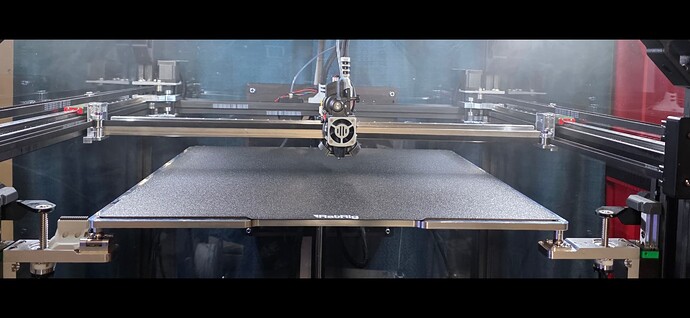

Ratrig

Right now I’m enjoying the hit print and walk away aspect of the H2D, it’s definitely easier than the jubilee. Will run this for a bit and revisit DIY when the INDX is released. I’m more print quality oriented and for now want to focus on designing parts rather than tweaking the printer, unfortunately I keep finding myself thinking about adapting a BL hotend to a jubilee tool and I have to remind myself I promised the misses I wouldn’t spend as much time futzing with the printer if I got the BL.

Just when my temps when up in my house over 10F… The humidity also… For my ABS, more sensitive brands, they seemed to not print as smooth (surface finish) on my P1 machines. I honestly can’t say with the H2D as of yet, as I have only used the stock profiles for both ABS and PETG-CF(I use the PETG profile), and my temps in the home have remained at 70F… Additionally, I am only using Bambu ABS and PETG CF now, so my results are pretty darn good(thankfully)…

I have some nylon that I want to try, but haven’t dried it yet…