If Bambu has to program using two different nozzles by scratch I don’t see it happening for a very long time unless there is an open source they can take from.

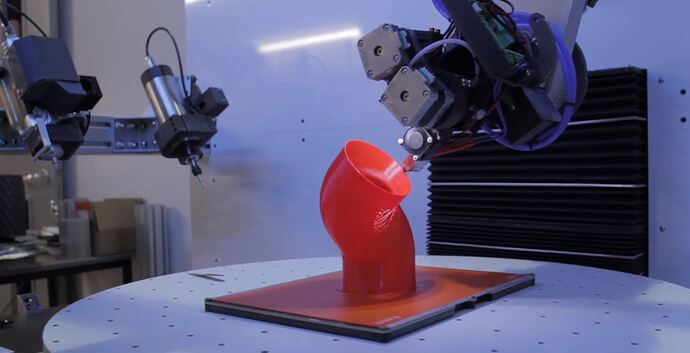

When non-planar printing reaches a mature state for mainstream use, we’ll finally see true 3D printing — rather than the 2.5D layer-by-layer approach we’ve relied on so far.

I experimented with non-planar printing on my X1 Carbon some time ago, and while it was definitely interesting, the current toolhead is far too limited for this kind of motion. At this point, you still need to manually hack the G-code, and without proper surface-aware motion planning or collision avoidance, it’s surprisingly easy to crash the nozzle into the model.

That said, once non-planar printing becomes practical, it will likely solve many of today’s limitations — and, of course, introduce an entirely new set of problems ![]() .

.

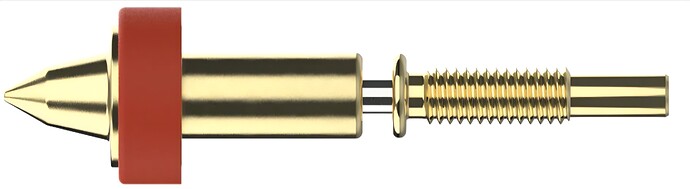

You probably already know, but if you swapped the x1c over to the revo setup, you could use this. Cooling would lack, so you would really want dual aux fans too. Because of the added distance from the part cooling fan to the part.

Im really interested in 5 axis printing.

One of the challenges today is that many established 3D printing companies appear hesitant to embrace disruptive innovations, and in some cases, actively work to limit open experimentation. There was a promising DIY project that included both a non-planar slicer and full hardware blueprints, but it has since disappeared entirely — likely due to external pressure or lack of sustained support.