I used PLA-CF for the first time yesterday (AMS) and at the end of the print I got an error message that said it was impossible to unload the filament… I I made several attempts but without success… we hear that the motors are struggling… Finally I heated the esttruder to 270° and I had to pull extremely hard on the filament which ended up coming out little by little. small while still pulling… I pulled 1.70m of filament out of the machine, which makes me think this one must be tangled up somewhere… but where???.. I don’t know what i would have done if the thread had broken when i started pulling…is this a known issue? has anyone had this before?

The filament was probably messed up just above the extruder gears which prevents it from coming out.

Pulling “extremely hard” was probably a bad idea, don’t do that. Even if you get it out, there’s no telling if it will come out of the PTFE tube. Even if it does, the way the extruder is designed there’s a high likelihood that it will just shave off filament, and those shavings will be in there to mess up the next time.

I’ve had this happen three times with PLA-CF (generic brand) right after printing PAHT-CF, twice just yesterday, I took photos so I could do a write-up about how to fix it. I’m thinking the heat may have had something to do with it

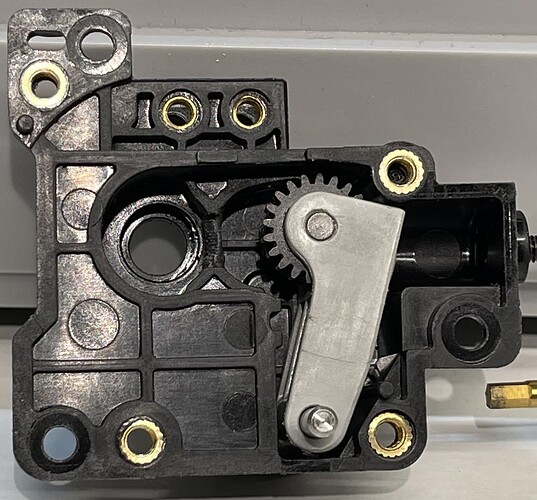

Here’s what the jam looks like when everything is apart.

Yes, shooting is definitely a bad idea… but I was furious!.. a new machine!..![]() I won’t do it again… I promise…;-)… I I will go and see in the belly of the beast what is going on at the level of the extruder… Thank you for your answer… I await your article with great interest…

I won’t do it again… I promise…;-)… I I will go and see in the belly of the beast what is going on at the level of the extruder… Thank you for your answer… I await your article with great interest…

that said, 1.70m is a very long to hide in these gears…

I had a brand new but apparently a wet spool of PLA from Matterhackers that in the course of a day jammed the extruder 3 times in one print over the course of a couple hours before I decided to switch spools.

But a single 3mm piece of material jammed up the ENTIRE thing and required that I take the entire head apart. Which is removing the hot end, removing the extruder, opening the extruder, and completely disassembling it. Here’s the instructions: Extruder Clog | Bambu Lab Wiki

What the video does not mention is what happens when you have all that filament in the PTFE tube and how to get it out so you can start the process. Especially if your AMS is sitting on top of your X1C and you can’t move it out of the way to open the top glass until you cut the filament that is stuck in there. The easiest place is to remove the tube from the top of the head (30 sec mark in the video), once you pull the tube out of the head you can snip the material and pull it all back. I have also had some success separating the tube at the connection on the back of the printer, but you have to force things a bit.

Now you can get your AMS out of the way, and start taking things apart.

As a side note… I now dry all my filaments when I receive them and put them in a vac storage bag. Having to do that process 3 times in a day SUCKED! But now I am a pro.

Hello, If I have to spend my days drying my filaments, I stay at PRUSA…;-)… I had the problem with a new spool of PLA-CF received with the machine (10 days ago) and just unpacked… Is it possible to receive wet filament?..

Luckily I have only had one spool of PLA show up this way.

I really only dry filaments that come in bags where they are not properly vac sealed from the factory. Which was the case with that spool.

So I’d say generally it’s a non issue.

Ok again stuck with another spool and this time I dismantle the extruder… and everything is normal… so where is it stuck?.. in the rear hub?

Yes. Some mfgs use water to cool the filament during production. Some filaments are very hygroscopic that even 4 or 5 hours in a humid (50%) environment will make them unusable until they are dried again.

You will need to disconnect the PTFE tubing on both sides of the hub on the back of the machine and just start removing the filament. Pull through the hub only in the normal direction of the filament through the hub. You may caught up inside the AMS, and will have to check the wiki on clearing that jam and inspecting for problems there.

Ha good… well we’re going to have to dry, dry, dry…![]() Yesterday I was indeed able to take the filament out through the rear hub, but impossible to disengage the PTFE tube (the one with the spring)… I then had to pull a little hard, but not to the point of doing damage… For the record, the filament that is causing the problem and which is currently in the dryer is PRUSAMENT PLA filament…

Yesterday I was indeed able to take the filament out through the rear hub, but impossible to disengage the PTFE tube (the one with the spring)… I then had to pull a little hard, but not to the point of doing damage… For the record, the filament that is causing the problem and which is currently in the dryer is PRUSAMENT PLA filament…

Small question: Does GOOGLE translate well from French to English?

If that is what you are using, then yes.

There is several of these type of buttons ( Printables ) that makes removing the PTFE tubing from the push connects much easier.

Cooolllll i try this one: Printables

Can’t BambuLab just do it right and make a PLA-CF that does not cause so many problems?

Had the same issue today. Wanted to print first time something with the in the package delivered CF material and jammed … AMS was not able to retract.

I was very annoyed and disappointed from this horrible performance. That issues I expect from a 300€ printer and not of a 1.500€ machine.

BambuLab should solve that issues very quick or erase selling those materials if they can’t handle it, as I sadly bought a complete 1kg roll on top of the sample one.

same problem here jammed up on a two color print using the stock PLA-CF… fortunately i bought a matte black PLA with my original order so switched to that and have had no issues…

Same issue, but now I dont use AMS anymore and print PLA-CF only from the single feed in the back and dont have problems anymore. Standard glued coolplate.

It prints fine with the .06 nozzle.