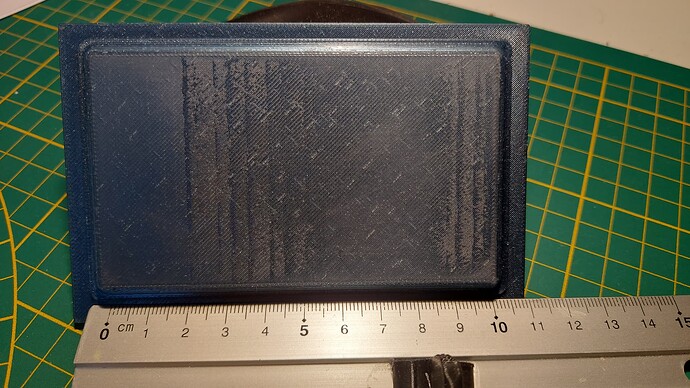

Hi, Having (again) this strange phenomenon:

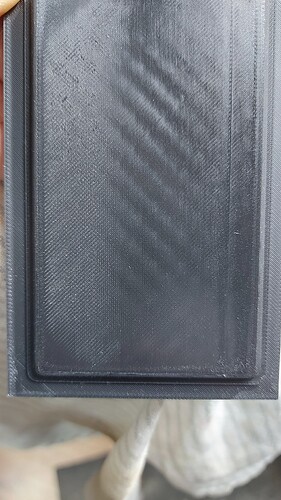

Ironing starts off very nice and then suddenly starts to create a rough aspect.

The toplayer without- ironing looks normal and acceptable but when ironing is activated I get this

aspect as on pictures.

Since the first 22 mm are ok and nothing changed in the meantime, I rule out the filament (PETG, of TM3D company) the model is printed on the engineering plate and stays perfectly flat so no shrinkage; the plate is always calibrated before each print;

pls note that after ironing I had to sand the surface as it was not usable, however the issue is still clear.

hope to get some suggestions

rgds Tom

Gut feel is to increase your ironing flow by 5-10%

More practical solving: Print this, using your current projects settings

Make note how the surface changes as you increase specific speeds and flows

Find a swatch that looks ragged like your actual print

Alter your ironing flow/speed in the direction that the swatch seems to show improvement on. (if the swatch is ragged at 10% flow, and smoother at 20% flow, increase your ironing flow. Or vice versa. Or if its more ragged at slow speeds and smoother at high, up your speed. or vice versa.)

Ironing behavior is incredibly touchy and will change per filament per nozzle per process if you demand perfection

Ironing…

Needs a well calibrated filament to start with.

In the pics I can only see the sanded result, so I assume there were already unwanted artefacts on the normal top layer.

Double check the filament calibration first.

Then print a 25x25x3mm test cube.

Adjust the nozzle temp up by about 5º to see whether or not this improves the top surface quality.

Check if a slower speed for the top layer infill makes it smoother as well.

Once you get a near perfect top surface start the test for the ironing.

Start with the default values but ensure the infill goes 90º to the top layer infill.

A ironing flow between 5 and 10% is usually enough to get a shiny surface if the filament is well calibrated.

It really helps to set the ironing spacing to 30 - 40% of the normal spacing as this kind of overlap smoothes out the surface a bit over two times.

1 Like

Thanks for reply; I made 3 tests with PETG (supplier TM3D netherlands). this is what i did:

test 1 (with sp20/flw27) best result sp10/flw15%.

test 2 (with sp10/flw30) best result sp30/flw15,20,25 and 30% were acceptable

test 3 (with sp20/flw25) best results sp10/flw15% and sp30/flw25 and 30%

which gave me no clue what to do.

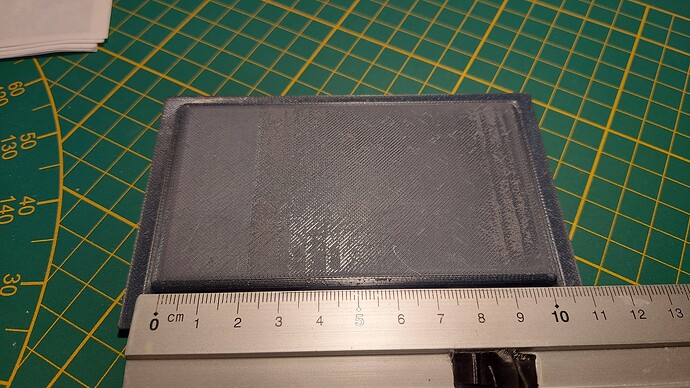

Did a bigger surface (60x100) with sp18/flw20 ref pict PETG 1.

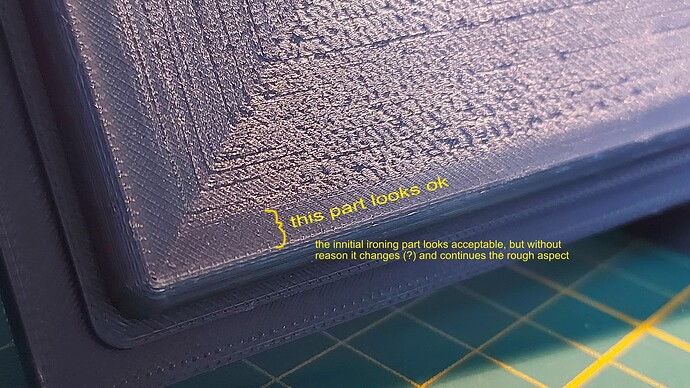

Since I experienced previously that the ironing was acceptable up to a small area in the beginning and suddenly switched over to rough, I wanted to see what happened if ironing was set to concentric.

Again the first couple of lines were ok then suddenly a big change on the next lines and the rest is printed fur. pict 2 and 3.

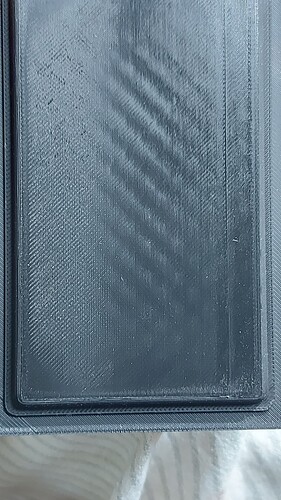

Changed to PLA (same supplier) followed suppliers’ instructions ironing rectilinear; sp30/flw10%.

ref pict PLA 1 & 2.

It looks as if the nozzle does not keep the same distance from the layer all the time. Again the right side is more or less acceptable (and could probably improved by raising the flow somewhat.

But on the left side nothing has happened, it looks qs if it flew over without doing anything. although I have seen it administer filament.

Unless you have a suggestion what to do next, I am losing my patiece with this thing. May be I just forget about ironing and find another technique to create a thermoform-mold with smooth surface.

Assuming that you used that 5x5 test block, each little block has it’s own embedded ironing process parameters, so whatever you put into global shouldnt be having any effect. So… getting different results from 3 identical runs is… not encouraging lol. Check around the forums for people who found some screws loosening over time on the A1 mini toolhead. IIRC they were behind the assembly that holds the nozzle. Out of ideas!

ASIDE:

If your end goal is mold buck forming, I would consider using ABS + vapor-smoothing [acetone, others]. The process kind of sucks, but chemistry will do 100x better smoothing than mechanicals here.

1 Like

I considered ASB but that is not advised for the A1 nor the mini.

On top of that, my friend has a P1 and tried the ABS but the smell seems to be terrible and is definitely toxic.

Right now I returned to the first PETG print and sanded de rough toplayer.

Asa de 2000 and 3000 sandpaper are in it will become acceptable for the toplayer. I think I can live with that.

Will check the screws behind the extruder anyway. thanks for the tip.

rgds

Tom