For about the same price range, you can get this thing for true 85C chamber temp, dry 4 spools, dry 2 chambers separately with appropriate temperature, feed them much more smoother, feed to multiple printers, yeah of course it doesn’t come with AMS feeding but this thing is probably the dryer+drybox in perfect mode without annealing capabilities.

By damaged, what types of damage do you get? Personally, I feel like the safeguards are too conservative and haven’t come close to causing damage to any filament, even PLA being dried a little hot.

On this, I have seen the motor drive so hard during a tangle that it could easily cause filament to break in the path. But other than that, I haven’t seen anything troubling.

I’m assuming this is in regards to 90A and softer? Personally, the 95A and harder have been Bambu easy (aside from having to break the filament paths down and rebuild them).

If the statement is specific to softer TPUs, the HTs are not terribly good for the 90A’s and softer filaments. Bambu’s suggestions seem to work well when followed and I don’t believe the HT has a path that is free enough to work with 90 and 85A, never mind the rollers.

I’m still a little annoyed at how poorly engineered the H2D is for TPU, but the workarounds seem to work good enough.

Hi, which filament dryer do you recommend? I bought the standard H2D, but I’ll need to buy a filament dryer to print PETG HF and, in the future, PPS-CF.

And it would be nice to have a dryer that can dry and print at the same time.

Good explanation, congratulations.

I’m glad you read your thread, otherwise I wasn’t going to buy the AMS HT.

I didn’t want to pay €350 for the AMS 2 Pro just to dry filament.

What do you recommend?

I had filament detection enabled at startup, but it gripped the filament so aggressively that I had to disable it.

Mainly print TPU 95A HF

That new creality dryer looks the goods, I’ll buy two when they become available.

one slight issue I had is that for some spools it might need weights to hold them down on the rollers. I also put some grease on the internal edge of the lid insulation part (well, I don’t know how to describe it, basically a insulation layer of plastic piece that is right underneath the lid), so that it would have less friction when the spool got lifted.

If you can’t measure temps even close to 85 at the heater outlet, have you contacted Bambu about it?

As far as 85 being a bit less than useful as a drying temp, at least that was advertised up front.

The Space Pi x4 is great. For the first time also seeing a true temperature reading and it’s making a hell of a difference for me.

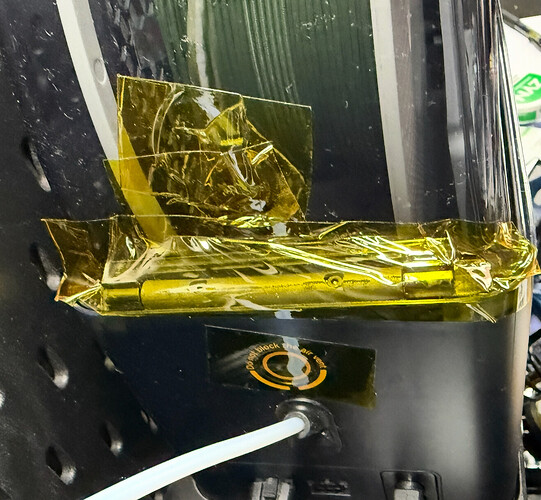

Only caveat: the build quality for the PTFE holders on the back suck… I made this model to improve it though – hope it helps ![]()

YOU ARE AWESOME AND THANK YOU FOR MAKING THAT!

I think the acrylic they’re using are having slightly more friction than it should have, when a spool has been lifted due to low weight. I’ll see if I can make something for it.

Please ping me if you make something for it!

I always load my filaments with those silica things in the center of the spools (so I also regenerate them while drying the filaments), so haven’t had issues yet

What filament dryer is that?

The Space Pi X4 from the archnemesis

Yeah, I do that the same but it’s still not enough weight to keep it down lol. My temporary solution is to apply some grease on the insulation layer

I think I’ve possibly located the source of the moisture intrusion. The hinge.

I used kapton tape to seal off the auto air vents first. That made no difference, the RH still climbed. So it’s not those.

Then I sealed off the lid hinge. What do ya know, the RH stopped climbing and after a while actually started going down.

I’m going to try and seal off the gap around the plugs too to see if that helps.

I wonder if a thicker seal would fix it. Being the hinge side, im guessing the sealing pressure isnt tight enough. Maybe the seal slightly shrinks after being heated

You would think that’s where the most pressure would be. Maybe it’s putting too much pressure on it. Enough to deform it slightly and cause a gap. I’ll have to look at one of mine a little closer next time they’re not in use.

It’s been a little while since I did this now and the RH would have climbed at least 4% or 5% by now. It’s holding steady!

This is what I was thinking. The hinge side is fixed but the other side closes pretty tight. If I get spare time, ill use some putty in the seal to see where the loose points are

Awesome art skills incoming

Too bad that galaxy fold 7 lost the spen support

I agree. Went with the s25 ultra this time.

Ohh I gotcha. Worth a shot!

It may not even be the seal, but what’s behind the interior lower plastic shell in that area. Snagged a pic from the Bambu store of the shell. I may have to take one apart to get a closer look and see if where the screw standoffs are is sealed or open to the lower interior.