Among all of the Bambu Lab products, AMS Lite and AMS HT might be my worst picks. While AMS Lite is terrible for filament storage, it’s at least featuring fast color swaps. But AMS HT, after use of a couple weeks, all I felt is total frustration.

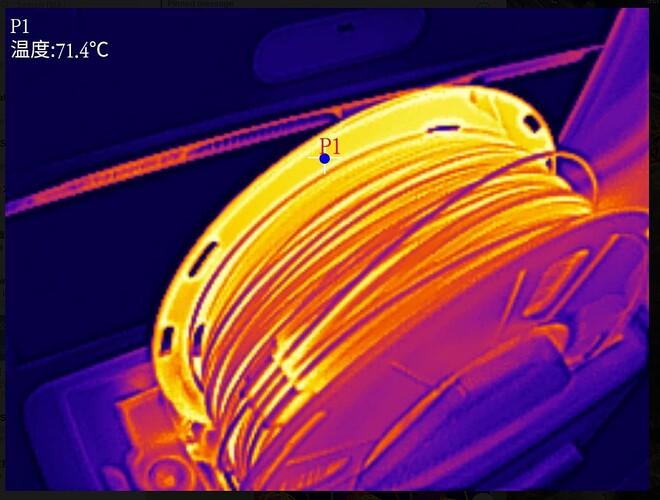

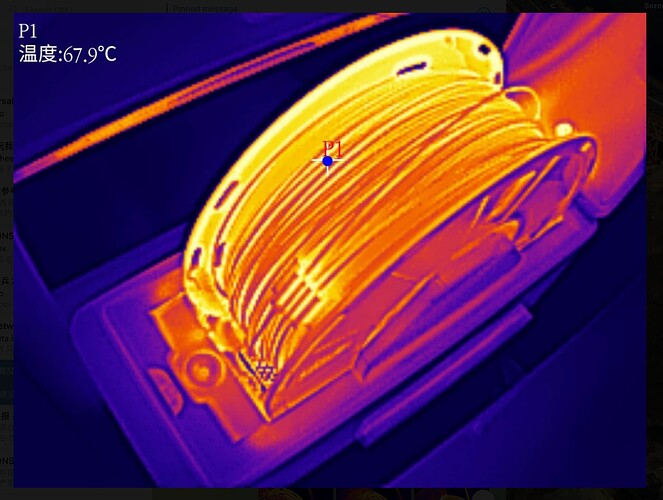

1. The filament can only reach 70C when the heating was set to 85C.

I don’t care what’s the excuse, but yes this is what you get from 16C room temperature in Sydney’s not so cold winters.

The branded “85C” was only achieved from the hot air vent. Not from the otherside of the chamber like most other filament dryers. Even the cheap cheap Creality Space Pi is doing it right. And the AMS HT is barely reaching a higher temp if not equal, when the Space Pi is set to 70C.

2. The bypass outlet design is TERRIBLE in every possible way

First, it’s on the lid, where it moves with the lid when you open and close it.

While it might not be an issue alone for TPU, it would be an issue for PPA-CF or other strong but brittle engineering filaments. Yes, there is no way to use the outlet without breaking the very brittle filament, because when you’re closing the lid, bang, the filament snaps.

Second, it has a terrible designed outlet angle, introducing more friction when feeding TPU. So it’s not good at TPU as well.

Any other sensible drybox/dryer manufacturer is at least putting the some of the outlets on fixed positions. Why it has to be fixed? Because you would not introduce unnecessary filament breakages.

Creality X4 for example

Sunlu S4 for example again

Both also have outlets on the lids, but that’s not the ONLY option they have.

And did I forget to mention how much easier it is to feed TPU smoothly from these dryers to the printer?

3. Tiny dessicant space to keep the internal space dry, while the sealing isn’t the best notch.

Without extra modification you can expect the internal RH to raise by 1% everyday. With extra modification to add extra dessicants, you can expect it to raise by 1% every two or three days. But still the sealing/the ability to keep the chamber dry is terrible compared with OG AMS or AMS 2.

So, save yourself some money, if you’re not already fully maxed out with your current AMS OG or AMS 2 Pro setups. The AMS HT is really not worth it for what it is.