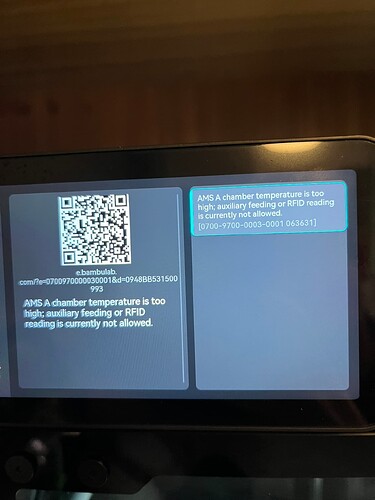

AMS2pro Chamber Temperature too high

I just got this error, with the printer informing me that RFID reading and auxiliary feeding is disabled because the AMS2 chamber is too hot? So you pretty much cant print while drying, and you cant print AFTER drying?

Error Code 0700-9700-0003-0001 06363

Funnily enough, theres no result on google regarding that. Couldnt find a wiki article either

There’s a temperature threshold that prevents some features when it’s been hit. You can wait a few minutes for the internal temp to cool off and then try again. Off the top of my head I think it’s either 45 or 50C?

The ams is open and get air from the AC which currently is on full blast. The error hasnt cleared in 30 minutes already. Worse even , I still cant find any info online , this is something that was not mentioned anywhere apparently and its kind of breaking the workflow here. What you normally expect is “ok i cant print and dry, ill dry and then print” but here comes this and says no, you still have to waste more time…

Wait what!? Seriously? 24@525252525

What is your AMS temp at?

35 Degrees now, left it open about 10 minutes but honestly, I dont want all this drying to go to waste JUST to be able to use it normally…

And just in case, its not on wood or paper, its on a thin tin stand which is impossible to hold heat, its room temp already

And what does auxiliary feeding mean? I still cant find an article or something on this error. the QR just takes me to the generic wiki

Wait it’s room temp and you’re still seeing the error?

no the “stand” its sitting on is room temp. The ams itself is currently at 32. Yes the error is still there. Printer DID start printing though, feeding from said AMS so I really wonder what the auxiliary feeding “disabled” means…

At this point I think it’s a bug. I have printed when the temp was over 40 before. I’d recommend pulling your logs after the print is done and power cycling everything. Then making a ticket with said logs.

I have noticed that errors tend to stick around for a while though, so it might just be the initial error that is still there

Most of errors that have poped for me are gone the moment the issue is resolved. This might be persisting as its in print currently and doesnt really circle check “i guess”. Still this is a bummer, and also, @SupportAssistant , this issue needs an article in the wiki. Even google returns 0 results.

1 Like

Interesting, I’m pretty sure I’ve seen the laser calibration notification persist for a while, and there’s seemingly no way to get rid of the filament auto-refill notification either (until a bit after the print). Maybe it’s a certain class of notifications or something that persists

Whatever the reason, its more “worrying” that you cant find ANYTHING relating to the code or error title online

1 Like

I know they have a long list, but the fact that it isn’t all-encompassing is very frustrating at times

I mean , since it’s got a code, its a known message/issue, so probably just neglect if anything.

I’m having this situation after the last firmware, but unlike some, it’s not the end of the world, I go have a cup of tea and wait for it to cool down.

1 Like

I can see where you come from, but this is not the case of a machine sitting on a shelf and printing decorations and ideas for hobby, its part of a production line, and this kind of delays are backbreaking, especially when you are at about the 30th workhour for the “day”

If this is living in a production line environment, add 30 minutes to your schedule after drying before the machine is live, move your drying schedule back 30 minutes, or reduce dry time by 30 minutes (maybe even 15). You now know the limitation, so you can put it into your existing schedule and work around it.

If you are wondering why this is a limitation, filaments can soften at hotter temperatures and can jam up the AMS gears. This is a safety to prevent damage to the AMS (and prevent unnecessary support tickets). I much rather adjust a schedule than have to open up the AMS and possibly order/replace hardware because I was impatient.

1 Like

Yeah nah, no time for that. Wont be using the drying function anymore except if in need or i can forsee enough downtime. Already have 2 sunlu s4’s, ordered couple more to be down with…

No time for what? If the printer is scheduled to start at 7:00AM, have drying stop at 6:30AM or 6:45AM. I mean if you have a ton of other dryers then more power to you, but it seems like you’re looking for a problem instead of a solution to me

2 Likes