I had the same problem on my x1c, the pftg tube wiper is a bad idea, sometimes the nozzle even throw the poop on the plate and ruin everything. I tried to find mods on makerworld but no perfect solution.

Then i realized that i don’t have to use 3d print to solve problems in 3d print. : ) Anyway there is a very good alternative I’ve been using

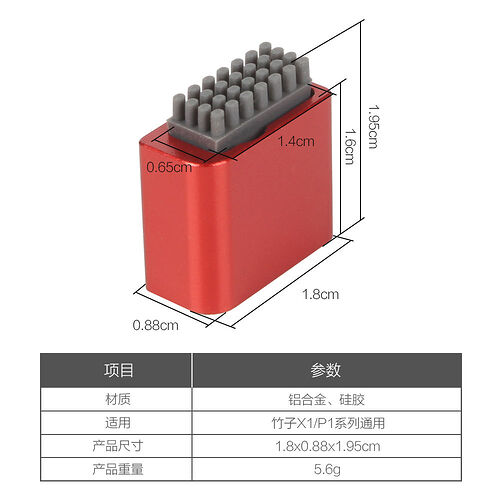

Not sure if it is available outside China, here it only costs 6 RMB and comes with 2 backup brushes

It cleans the nozzle rather well, the worst case is the fiber gets stuck in the brush but never brought to the plate, so I’m okay with it

1 Like

I’ve not had too much trouble with build up. I don’t do manual calibrations and don’t really print PETG all that much. My solution for when my OCD kicks in and the nozzle needs cleaning is one of these little brass brushes. It’s fine enough that it doesn’t trash the silcone sock and heavy enough to get the nozzle clean.

1 Like

After finishing a PETG print, I heat up my nozzle and clean it using a cloth and a brush like this one:

1 Like

Hey…so you think if i dry my petg than default bambu lab nozzle wiper will do the job…i am afraid of purges in middle of print or color swap…how dry is dry for you!??

Thank you

I own 4x Sunlu S2 dryers. I load filament in the dryers and set them for 70ºC and leave them for a minimum of 12 hours, but generally try and shoot for 24, before loading in the AMS for my print. With properly dried filament, PETG is not a problem for the machine. I print a ton of the stuff and my machine is 100% factory original.

1 Like