Some of you guys already know this, however, I found it interesting to actually test and wanted to share my findings with those of you that didn’t know and by test not guesswork.

I’ll start by saying I’m a retired Engineer…(EE). I’ve worked in the industry for over 40 years, globally. I did prototyping, form-fit-function design and testing requiring the use of our 3D printer for the parts. I was a manager in an environmental lab after that, testing prototype customer equipment daily. So much for background. I bought a P1S a couple years ago after I retired and here are some of my findings using ASA “actual real life testing”, No guess work here, no… I think, no… he said, she said… Actual calibrated real life testing. Your “actual” results may vary a bit.

I’ve read a few articles recently online (not here) and surprising enough reviews about the Bambu P1S not able to properly print ABS and ASA due to an unheated internal chamber and the max bed temperature of 100C. Well mine reaches 120C bed temp. As I said not here but quite a few articles on the WEB. I’m here to tell you, they are wrong! I use most all filaments however this article is specific and about ASA and the Bambu P1S printer. See the three test photos…

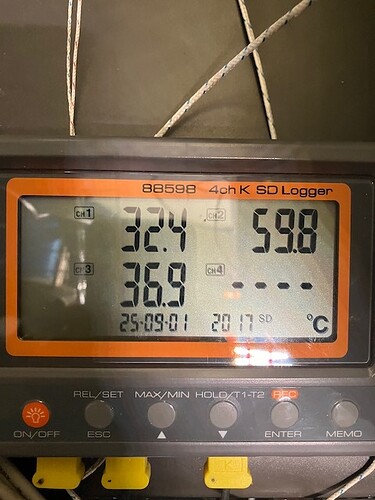

I’ll start out describing my printer layout. Fully enclosed P1S w/ AMS, thermal sensors in the top of the AMS (CH1), top center of the P1S 4” (101.6mm) (CH2) above the print bed THIS IS THE CHANNEL OF INTEREST, and one at the base of the printer (CH3) about 1” (25.4mm) off the base. I have a 2” (50.8mm) vent hose about 4FT (1.2M) long with a variable powered blower running out the window and a window Air Conditioner right next to the printer.

Test 1 was as follows:

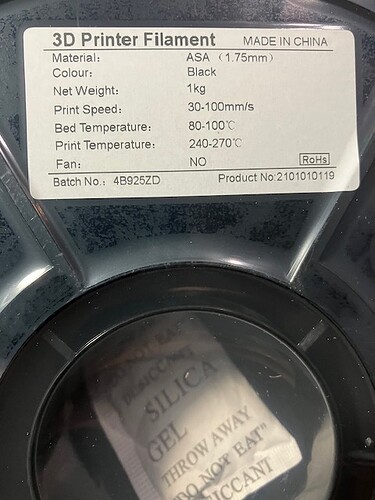

Cheapest ASA I could find on Amazon USA…1 Kg $15.99 US dollars on sale iSANMATE brand

All standard parameters selected by Bambu printer for .4 Diameter Standard flow ASA (I get better results using Bambu ASA setting) for all ASA I use no matter what brand. External Vent fan OFF (for test) HEPA/Carbon filter used.

Test 2 was as follows:

Cheapest ASA I could find on Amazon USA…1 Kg $15.99 US dollars on sale iSANMATE brand

All standard parameters selected by Bambu printer for .4 Diameter Standard flow ASA (I get better results using Bambu ASA setting) for all ASA I use no matter what brand. I removed HEPA/Carbon filter and used External Vent fan ON minimum speed just enough to cause positive pressure in chamber to vent (about 1/10th of turn) on speed control (very slow). I found the built in exhaust fan inadequate for venting when running a 2” vent pipe, understandable as it was not designed to run additional vent pipe.

As you can see from both test results, there is not much difference, no heater required even with inline fan to meet the recommended 50C chamber temperature. ISANMATE specs high-end met using Bambu ASA settings, see photo of spool

I have tested all cheap brands of ASA and they all work the same. For me the detail is much better than ABS and doesn’t smell near as bad.

Bambu has done a great job with this printer. It seems to me the online reviews are clearly empirical or hearsay guess work testing by the reviewers and clearly incorrect. Thanks Bambu I really enjoy this printer. So guys buy a spool of ASA and give it a try… OH and by the way, NO adhesion problems with the standard Bambu PEI plate, both smooth and textured, once cooled comes off very easy.