Hey guy what up with the high flow nozzle, I thought this would make my prints faster like Bambu labs advertised. I am getting the same time for my prints with the standard flow nozzle. I am on the latest firmware and HF nozzle is selected on my printer. Please tell me I miss something setting or this is a waste of money.

Bambu Lab still didn’t make presets for the HF Nozzle, needs more time from Bambu to be calibrated as well as the PETG HF profile for the H2D and HF Nozzle.

Just remove it from your setup and wait till they have a new firmware update for the machine and a new update for Bambu Studio.

Hope that helps, I learned the hard way lol.

I do understand what you are saying, but they had to test this HF nozzle with their own filament. So the settings should have been in the software when this HF nozzle was released. Also this was sold out two times so far what about all the people who purchased this.

I feel your frustration, many are in the same boat as you and me. Tbh, the whole H2D still needs calibration and profile presets and much more dialed in g-codes to be as good as the X1C.

It’s like when the X1C got released, there were bugs and profile presets that weren’t correct but in time Bambu Lab fixed them.

I agree they should have tested everything before making it available in stock but in truth I don’t think they did or at least didn’t do it efficiently. Instead they wanted people to have them in their homes ( Business Profit ) rather than have them in their warehouse for a specific period of time ( which cost $$$$ ) till they are calibrated correctly.

Another reason would be to have us customers report bugs and profiles that are not properly calibrated so that it makes their work easier to tackle any impurities in the process of printing.

So yes it will take time for them to do this, guess it’s just a waiting game for now.

The only thing that changes is the infill speed in the current profiles.

If you look at the store page for it, they got the 30% claimed improvement by printing a 300mm cube, a shape that is practically all infill.

I think there is a lot of profile improvement to be done.

Welcome to the world of hobbies. 3D printing has always been about community working together to find the best settings. They released the H2D and the high flow nozzle to let the community start using it right away.

As an early adopter you have the opportunity to try your own settings, share with the community what is working for you, and what isn’t.

If you do a few quick searches you will find people already sharing profiles for the high flow nozzle that will improve your print times.

It’s essentially a case of things not being as finished as they should have been at the time of release. But Bambu Lab isn’t the only company to launch half-baked solutions and then take their time to address the gaps. Given that they must have done internal testing during development, I assumed these profiles would be ready by the release date.

I actually bought another machine from a different Chinese company, and they did almost the same thing. By launch day, they shipped a firmware that was so unfinished it could even seriously damage the unit in certain cases—which is honestly almost unbelievable! ![]()

Quick update on PETG HF ,

I can confirm that the “Brown” color prints flawlessly on the 0.4 Standard Nozzle. Other colors I’ve tried so far are: Red, Orange, Brown, Black, White, Yellow, and Blue. They are all bad and leave some blobs randomly at different layers.

The White one being the worst of them all as it leaves fine stringing all over the model being printed as well as everywhere inside the machine, big hassle in cleaning the enclosure when you use it. ( Yellow as well )

Conclusion:

I think it is not related to presets or slicing or drying, PETG HF from Bambu Lab is just low quality material and you’re better off buying a different brand of PETG HF. The matte finish is better for me than the shiny PETG but I want a clean printed model so I’ll wait until Bambu Lab changes their PETG HF Filament to another manufacturer as their current one is just low quality.

I’m sure you really have had some bad results. However I have to disagree with writing off their material as “low quality”. I’ve done a lot of printing with BBL PETG-HF on H2D with default profiles and had almost perfect results. Some prints have ZERO trace of stringing and ZERO blobbing. Worst case, a few tiny wisps of stringing on a otherwise perfect print. I have invested in a blast drying oven and dried my PETG until the dryer humidity leveled off which was about 16 hours at 65c. Seems that PETG really doesn’t like giving up it’s moisture sometimes.

Caveat - the chamber cooling H2D does during PETG prints is stupid and has to be disabled for large prints unless you want warping.

I actually dried all the filaments for 48hr @65c so I can confirm there wasn’t humidity nor the filament was wet. AMS 2 Pro Humidity reading was 2% and my sensor that I have in the AMS 2 Pro also reads <4% so I’m 1000000% sure there is no moisture plus I live in a very dry place so yeah it has nothing to do with wet filament.

Even after searching around through the web, I found out many people having the same problems with other colors of PETG HF from Bambu Lab. Some, like you had good results.

Majority of people had problems and some actually complained to Bambu Lab and they sent them new spools of PETG HF.

Basically Bambu Lab knows they have bad spools so it’s a matter of luck if you get good spools of PETG HF Filament.

Conclusion:

There are way better PETG HF that work perfectly on the H2D so I wouldn’t invest in buying PETG HF from Bambu Lab, at least not now until they figure it out with their manufacturer and quality control center.

I agree on the BBL PETG-HF. H2D, all default profile setting and it prints perfectly for me (Standard flow nozzles). I’m even tempted to completely reprint a model I did with Polymaker PETG.

I just received a pair of HF Hotends I ordered from Aliexpress. A couple of questions please:

1- Does the H2D sense the HF hotends or do I just change the setting?

2 - Does this mean I go in and create a new profile for each filament for HF?

3 - Do I increase the volumetric flow rate higher than the filament specs or just leave it?

4 - What should I expect from adding HF nozzles?

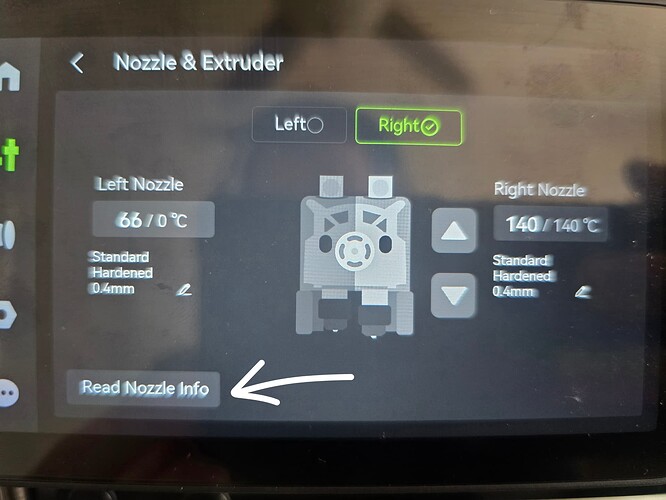

- It will only auto sense them if you click Read Nozzle Info from the Nozzle & Extruder menu on the Printer itself and IF your aftermarket nozzles have the little code(sort of QR code pattern) on the front. Otherwise it will only throw a code if you try and print and it recognized at the start of the print that the nozzle is different from the sliced file.

- Bambu has only set up some filaments with the correct volumetric flow rate for use with HF nozzles. I change my setting for those filaments based on my manual volumetric flow rate tests.

- Only change it based off of your actual test with a volumetric flow rate print.

- Decreased print time on files that actually use a filament with an increase in volumetric flow rate and LOTS of infill. Small files with little infill you wont notice much of a difference at all. With PLA basic and PETG HF, I can actually print in Ludacris speed for proto types and they come out pretty darn good.

I tested the aftermarket HF hot ends from Ali and their flow is no better than standard flow OEM bambu nozzles.

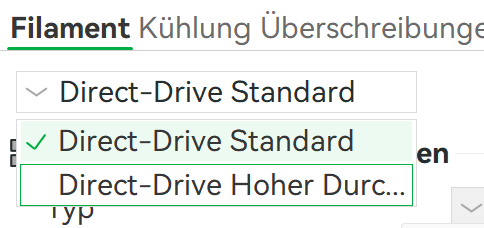

Oh guys, you also need to adjust the corresponding value for the max. flow rate in the correct profile. To do this, you have to switch from ‘Direct-Drive Standard’ to ‘Direct-Drive High-Flow’ in the filament profile at the top and change the flow rate at the bottom, then it will fit.

Today Bambu has delivered new profiles and adjusted this at least in their PLA profiles and PETG-HF (even if only the same default value of 35mm³/s everywhere).

I have just printed a model with layer height 0.24, infill at 600mm/s and ,hitting over 50mm3 of flow when printing infill. It printed this as a champ. I am really impressed with both the extruder and the nozzles. even the standard flow nozzle does a great job when puched a bit harder than standard profiles dictate… I do believe that there are some gains in this printer regarding print quality and speed that the standard profiles are not net revealing. Regarding print time with the HF nozzle. It does not change the print speed that much, but what it does, it that I melts the plastic more uniformly when printing with standard speeds, so overall better print quality.

A simpler and more reckless way is to…

Go ludicrous mode hahaha

lol. Ludacris mode for me works surprising well with the HF hot end. The prints come out crazy good with PLA and PETG HF. I only use it for prototyping but I swear I get results better than what I see most other printers do. I get some VFA’s with PETG HF but almost none with PLA. If I’m printing normal parts I use standard mode as I want them to look excellent and have more time for layer adhesion.

Yes Ive had good luck with ludicrous mode as well, lots of flow overhead left in the HF nozzles beyond the stock profiles.

however I do seem to have weaker than usual layer adhesion (which is normal I think), so use with caution ![]()