I have an A1 mini which is a bed slinger. When doing tall prints with narrow supports many times the supports are knocked down due to vibrations when the print head and bed platform move between print locations. What is the parameter(s) I need to change to slow down those jerky movements?

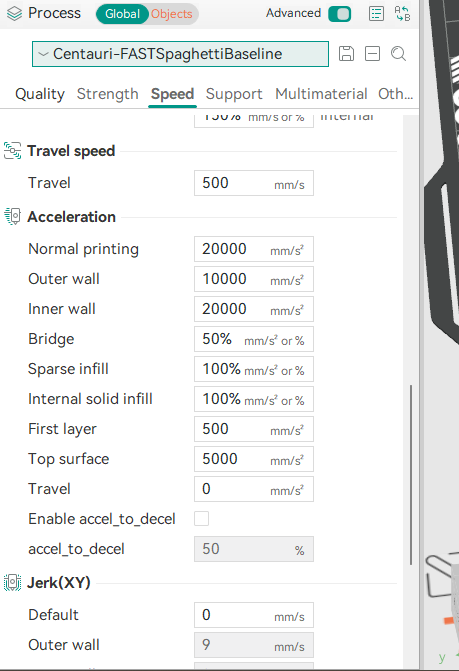

Global process → Speed tab → Speed, Acceleration, and Jerk

And I thought the purpose of this forum was to help those having problems. Hummm.

Print head movement along the x-axis should not vibrate or knock down supports.

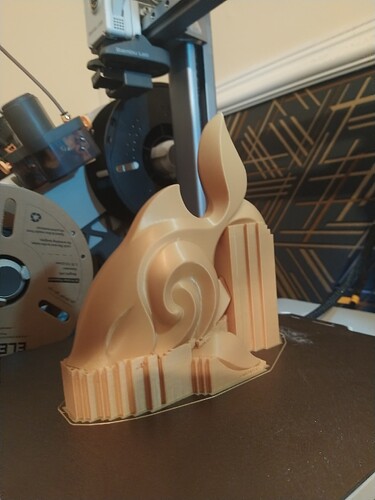

Rapid bed direction reversals along the y-axis can cause a print to break loose. The problem isn’t really vibration, it is momentum (mass x velocity) causing the model to test bed adhesion every time it changes direction. That is why reducing speed and acceleration is helpful, the speed changes are smaller, the reversals more gradual, so there is less stress on the adhesion layer.

Also consider rotating the model on the plate so that the widest dimension of the model and supports is along the y-axis, which should be more stable.

The supports themselves can be made sturdier with more walls, or by using Tree Strong rather than the default.

If a tree support is still falling before it grows tall enough to reach the model, try painting a small support spot on a vertical surface or corner of a model at half that height. That will force the support to branch out and brace itself against the model. It will not actually connect to the model’s surface, but it can stabilize the tree.

You might have gotten more responses by posting in the A1 forum where users are familiar with a bed slinger, rather than the P1 (core x-y) forum.

Help provided by users is strictly voluntary and provided on the helper’s schedule. If you feel entitled to faster answers you should contact Bambu support. Good Luck with that!

Thank you. I felt that was the problem. I’m new to this. Which parameters control the speed and acceleration and how much should they be modified by?

I did try painting a small spot on a vertical wall but all that resulted in was the slicing software generated a new support to contact that spot and the original support was unaffected. is there a way to force a week support to send a new tendril to the painted spot?

Those are the names of the literal settings that you asked for. If you don’t see them, enable advanced mode.

I thought you were being facetious. Under Acceleration there was no JERK so still looking for the best parameters to modify and how much to have them decrease.

Bambu studio might not enable you to control the third derivative jerk per-line-type.

Orca and most other slicers will.

From process settings, orcaslicer reference:

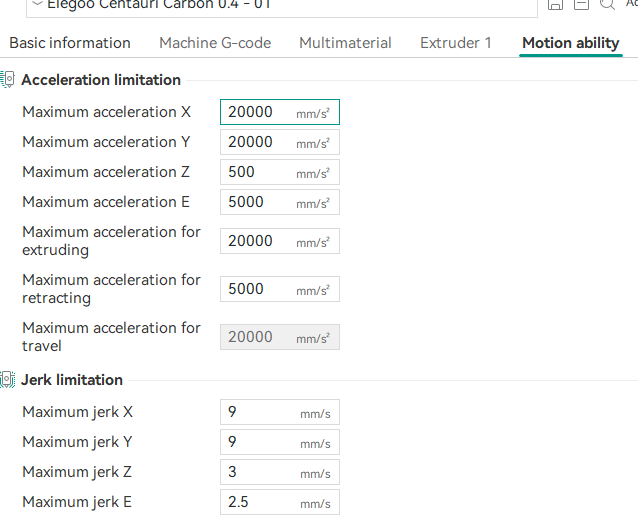

You may be able to adjust the machine’s overall limits, which then would feed down into the rest of the motion system, but you wont be able to adjust per-line-type.

From machine settings, orcaslicer reference:

I’m using Bambu Labs and there is no such setting. Is there some other setting which might work?

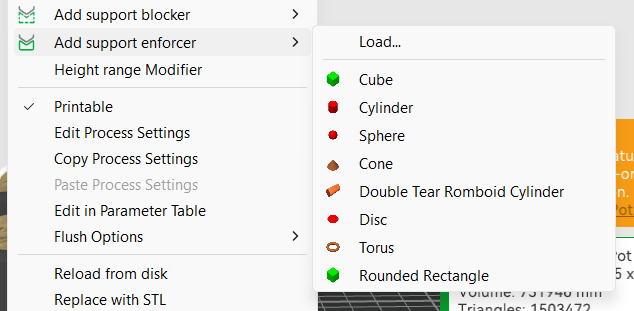

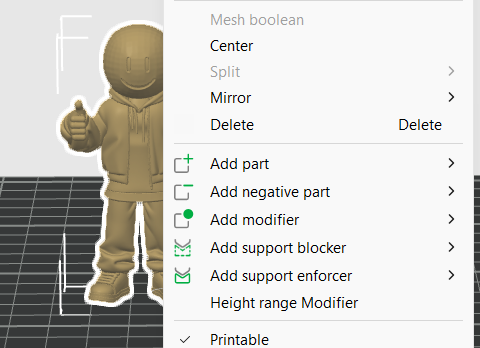

Add your own by using a support enforcer

you can then manipulate its size and shape to suit your models needs

Where on Bambu labs is that option for support enforcer?

Has happened to me before, run a full printer calibration then restart printer

Right mouse button ,while your model is selected

Bambu Studio Keyboard Shortcuts and 3D Scene Operations | Bambu Lab Wiki