If you use AMS TPU, what material do you use for the supports?

Almost always use the same material for supports unless the part is particularly sensitive.

For TPU in AMS, I use the stock settings for the object when printing on a Textured PEI plate. However, when using a Carbon Fiber Plate, I increase both the bed and nozzle temperatures slightly and apply glue as a release agent.

The donut I printed (previous post) uses this profile.

Lattice Donut TPU.3mf (3.7 MB)

Original model is this Voronoi Lattice Torus by FluffyCAT - MakerWorld

I’ll take a look. Thanks.

I can print your cap tomorrow after work using TPU 95A HF on a Carbon Fiber Plate with the X1 Carbon. It will be printed with a 0.4mm nozzle at a 0.16mm layer height, so we can compare the results. TPU for AMS prints almost like any other material, so I’ll skip that one unless you want a comparison on it as well.

Sure thing. Look forward to seeing how it turns out. I’ll try out your model once I have the settings dialed in a bit more. Thank you.

You can try the attached project—just update it with your printer settings and see how it prints. My profile is on the slower side, but it works well for everything I print.

Just a heads-up: in my project, I use a Smooth PEI plate, but it’s actually my WhamBam Carbon Fiber Plate, not the original Smooth PEI or High Temp plate.

I’ll also attach my settings for your cap so you can test them with your own printer and plate settings. These settings are for a 0.16 mm layer height and a 0.4 mm nozzle. This is the one I’ll be printing, and I’ll snap some photos after work to share with you.

Cap for user_4098504420.3mf (355.0 KB)

This is how it looks with the profile, would need support. I use random seams so that to can be changed. I think you have a good start here.

Maybe a circular pattern + support and not random seams will do the trick. My settings are set for good support with TPU 95A HF, just activate normal support instead of tree.

Thanks for doing a test print. The results look a bit better than what I ran. I’ll try to tweak a couple of things to see if that improves any.

Speed and temperature are the key factors for successfully printing with any type of TPU.

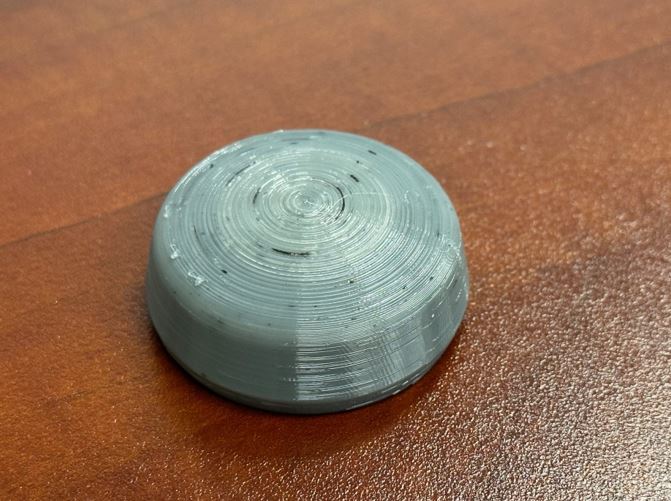

Here is the part that I made with your file. The only thing I changed was the resolution. I ran it at 0.08mm resolution.

The print looks quite good—there’s some minor stringing, but overall the results are solid.

I store my TPU in a heated dry box between prints to ensure it remains in optimal condition.

How does your cap turn out with those settings?

I haven’t had a chance to run that cap part again. Hope to do it this week.

Since the sphere turned out well, you’re off to a great start fine-tuning your printer. Don’t forget to add supports—I think they’ll be necessary.

Attached are images of the cap part ran with your settings. For the most part, I kept the same settings you had. Outer surfaces look much better. I did set to run with supports (tree auto), but it didn’t build with any. The inner surface had some issues, but still usable. I could probably re-run with normal supports and eliminate the “bird nest” on the inside but not that critical for this part. Changing to concentric patterns seemed to help a lot along with increasing the top shell layers. Thanks for the input and suggestions!

You could try using normal support; at least in the slicer, it provides full support for the cap. I haven’t tested this myself, but I believe it would be a worthwhile experiment.

Yes I think the normal support would be better. Might try that, but suspect that it will work out better.