Good morning everyone,

I’m currently running into a problem with my H2D setup – though I’m not sure if it’s the printer, the filament, or both.

I’m trying to print parts with Bambu PLA-CF as the main material. For the supports, I’ve tested PETG, PETG-CF, PVA, and Bambu Support for PLA. All filaments have been thoroughly dried, so moisture shouldn’t be the issue.

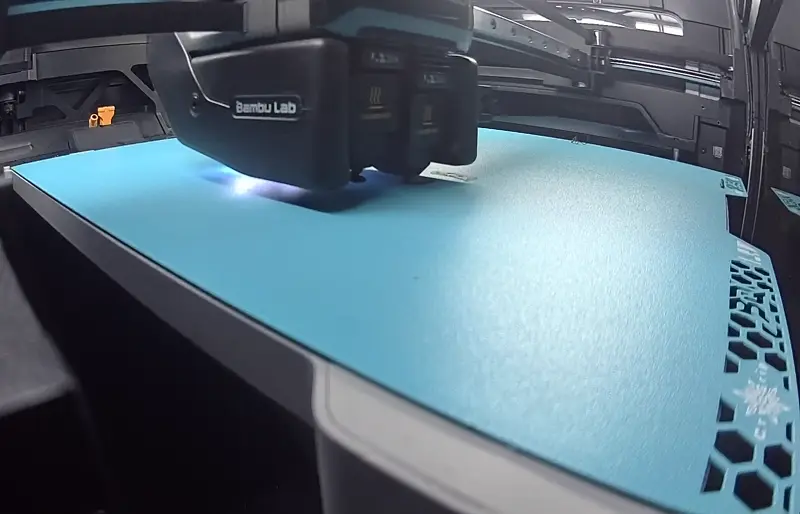

No matter which one I use, I always face the same problem: after the first few layers the supports lose adhesion and start to topple over.

I already tried different support types, infill settings, wall counts, etc., but the result looks nearly identical every time.

For context: these are parts I regularly print (grippers for industrial machines). They all share a similar core geometry, and in the past I’ve always been able to print the supports completely from a single material instead of just the interface layers – which usually makes removal much easier. Unfortunately, for this specific geometry that approach doesn’t work.

If I only use the support material for the interface layers, adhesion is fine – but then I can’t remove them afterwards. So in this case, I must print the supports entirely from PETG (or another material).

I’m aware that Support for PLA isn’t really meant to be printed directly on the build plate (since it hardly sticks there) – I only tried it out of desperation. Unfortunately, the result looked the same as with the other materials.

I’ve attached three timelapse videos that show how the supports fail with the different materials.

Right now I’m out of ideas, because it feels like no matter what I try, the supports just keep failing.

i’ve added the projectfile, i case someone would like to look at the settings

Problemfile.3mf (2,4 MB)