Just spent quite a few hours trying different methods of editing STLs and am quite happy with my end results.

The challenge was adding bearings and a 3rd gear into this model - as the turntable was a bit fast.

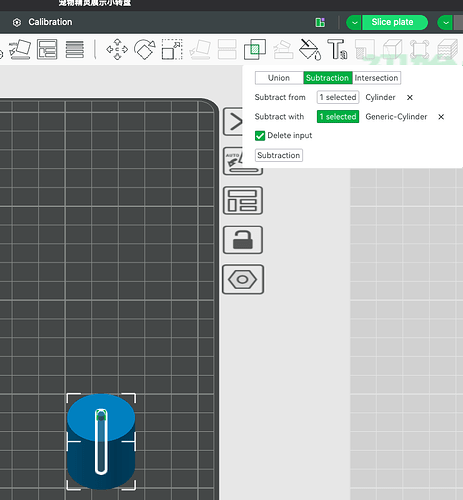

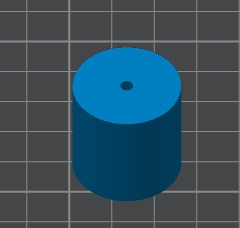

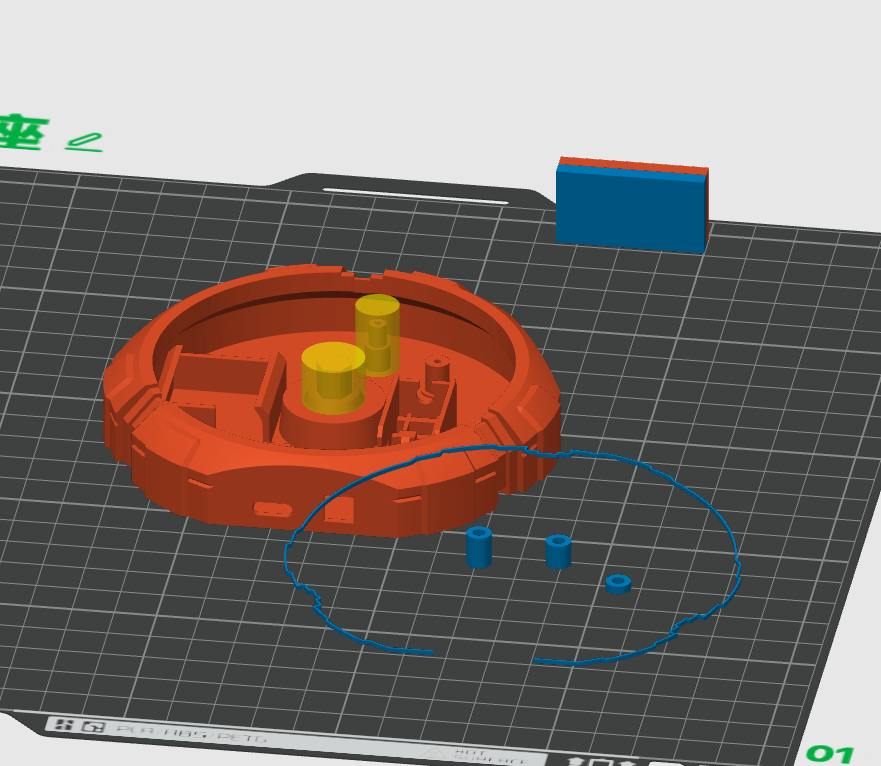

Adding the bearings wasn’t too difficult - I just created some cylinders the correct size using primatives - and then either used negative parts or mesh booleans to cut out room for the bearings.

Making the posts thinner so that they would go through the bearings was a bit more difficult. I eventually settled on creating a cutter shape using two cylinder primatives ‘mesh boolean subtracted’ together - to give me a hollow cylinder, then mesh boolean to remove most of the existing posts.

However positioning was quite tricky, plus also as I wanted to do more complex things, like make a new cog that was a hybrid of the two existing cogs.

I tried blender - but got the usual non manifold error issues.

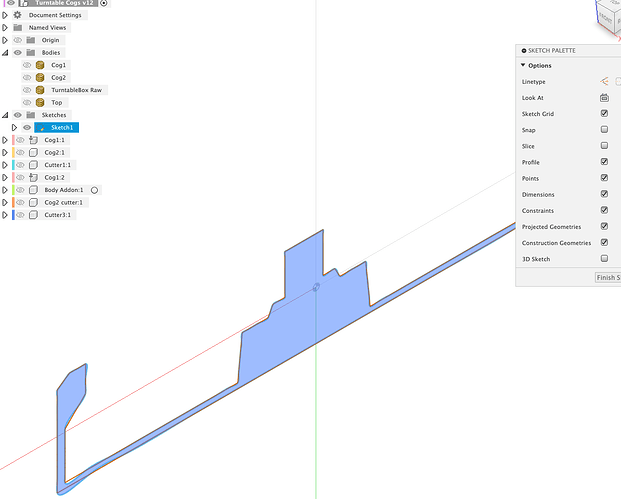

So moved into Fusion. But rather than trying to edit the mesh - I instead just imported it, and then created new sketches off of it - to create new normal Fusion parts for the cogs, plus other parts for the cutters / modifiers to be used back in Bambu Studio for the actual cutting / adding - using mesh boolean.

The key learnings I found were in fusion:

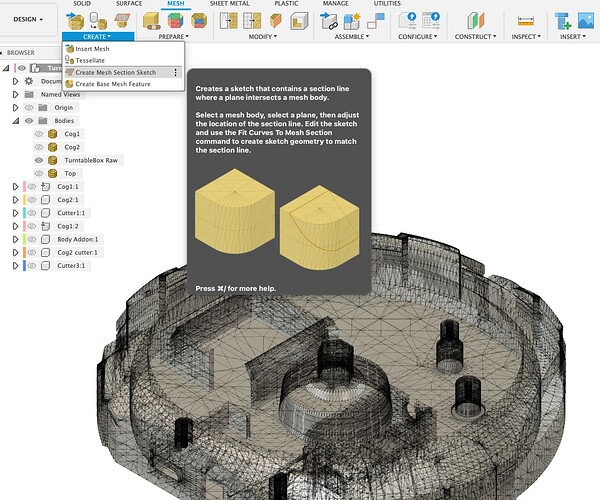

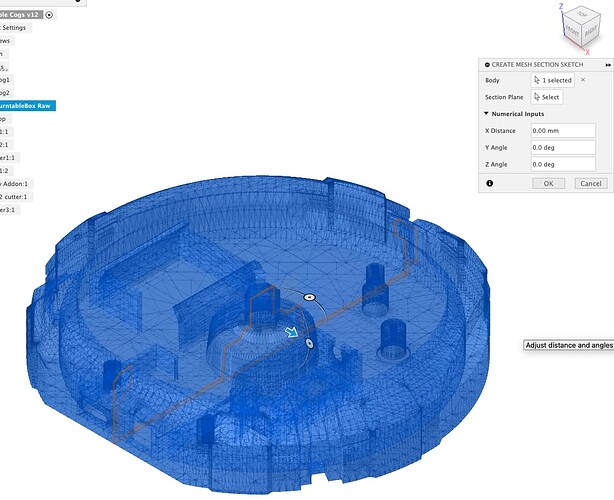

- Creating sketches off of meshes - using ‘Create mesh sketch’ - from the mesh workspace

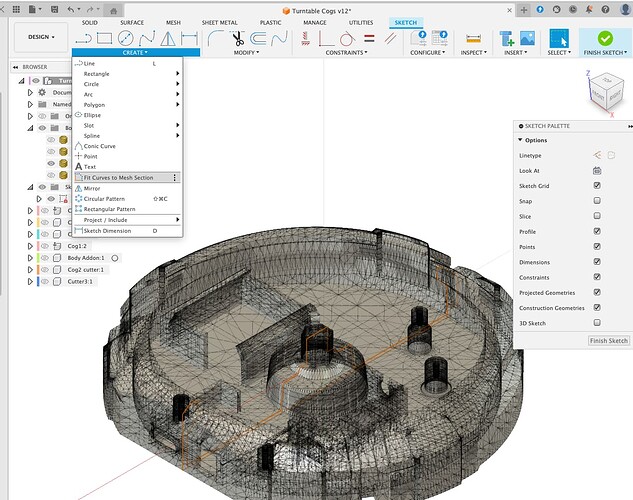

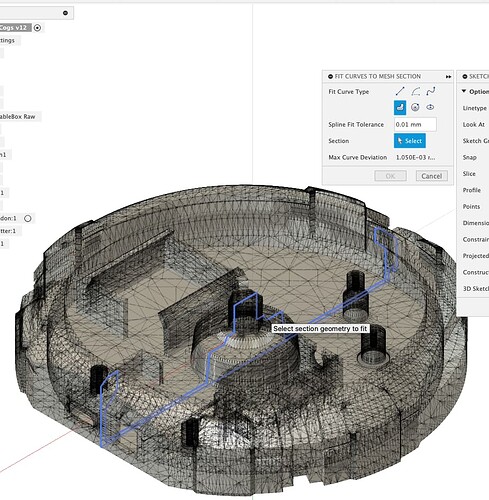

- That creates you a sketch - but it isn’t awfully usable - to make it usable - I found that within the sketch you need to create usable curves by using ‘fit curves to mesh section’ -

That then gives you usable profiles

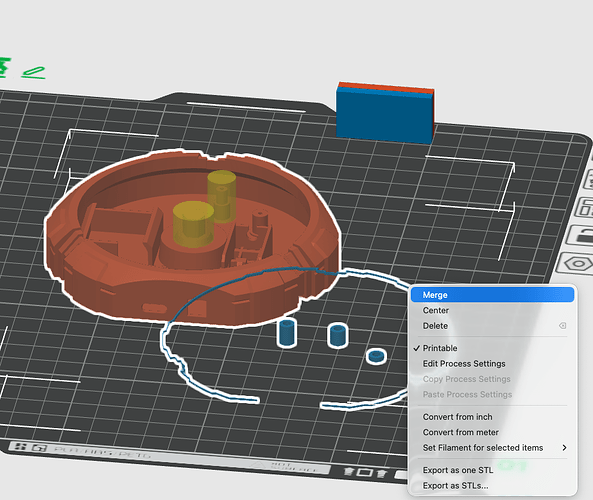

Finally - what I found useful was including some parts within the exported STLs that span the extent of the whole shape - to make positioning of the new parts or cutters much easier - as you can then just move them to 0,0,0 once merged.

See blue stl imported.

After positioning for unions it might be necessary to split out the object again and remove the positioning parts - (the thin line).

Fairly basic explanation I know - will probably create a video of this sort of thing if it is of any interest - but it does seem to me that using Mesh Boolean with shapes created externally is a lot more efficient than trying to edit big complicated meshes externally.

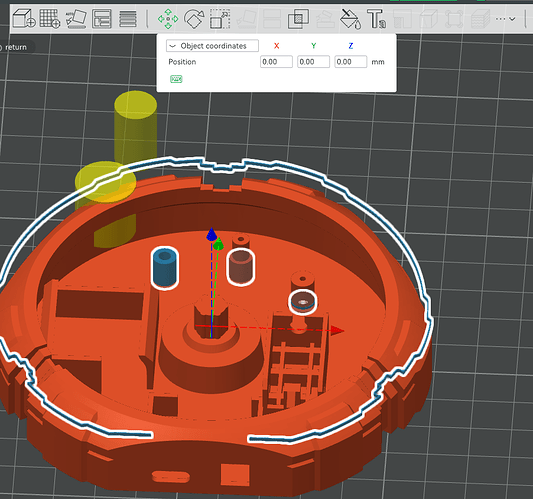

Final end result for me - is the third cog (left hand one) plus post to hold it and adjusting other posts successfully added. Middle cog created as a hybrid of the other two.

end result

Forgive the stringing - I’m trying to use up some very old, brittle filament - the orange stuff is very cheap Aldi balco filament bought in 2018 - which is so brittle I have to make sure I take it out of the AMS within a few minutes of every print (re instated one of my ‘overnight parking zones’ to help with this - see Makerworld).

I mainly put the extra gearing in for speed reduction - but it does make the turntable quite powerful - although might need to scale up the size.