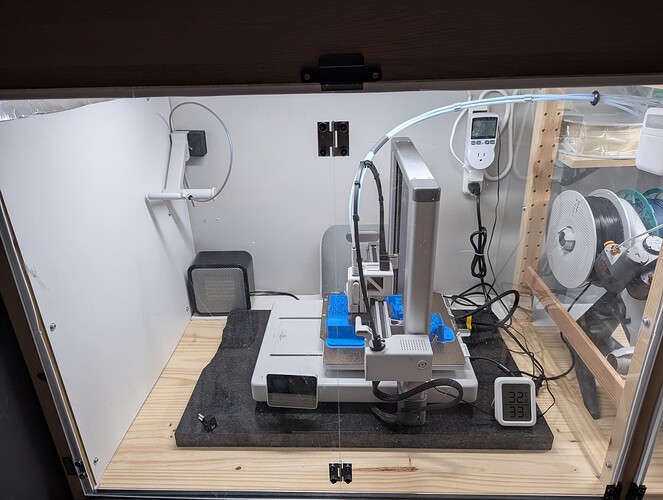

I recently added a heater setup to heat my custom enclosure to reduce my corner warping. But since than I have had extrusion issues.

Well after replacing the filament sensor, extrusion gears, multiple cold pull on 4 hotends, I think I found the reason: when I heated the enclosure, the filament wire got heated too, so it got more… Melty and so on retract movement and other pull on the filament during the print, the gears couldn’t properly move the filament making it test extrusion and in the process, further the issue.

I will try insulating the insertion tubes, but it seems my setup is either corner warp or extrusion issues, choose your poison.

I like the enclosure. Tell us more. How much are you heating the chamber to? Does this happen at lower temps? At what temp do problems begin?

I heated to maintain between 35 and 40C (bottom left box, measured just behind the front gantry column)

Before the heater, I hard warping corners problems a plenty. After the heater I had none.

Now I am trying to preheat the enclosure to 40 than shut the heater for the print time. Not great results, return of the corner warp.

Other idea is to insulate the feeding filament tubes, but that would be temporary if I had continuous heating in the enclosure (eventually the heat would migrate in the insulation if I don’t have cooling) still thinking on what to do.

On my X1, 40°C is too much for PLA. Usually, I try to keep the temp in the 35-39°C range. However, prints with ironing, large and flat top surfaces or many retracts are prone to rapid heat creep. Doing those with PLA, I usually stick to no more than 35°C.

Of.course, the A-series uses a different hot end which may be more susceptible to heat creep.

But I do reliably get good prints at 39°C (no ironing, large flat top surfaces, few retracts) while I get rapid heat creep at 40°C no matter what.

As for insulating, the PTFE’s, that’ll not really help with cold end heat creep as that happens below the PTFE’s. However, there was a disussion on the forum (quite) a while ago about blowing cooler air into the cold end through the PTFE’s using a small fan and a y-splitter. Not sure what the verdict was though.

Perhaps just stick to 35°C for now?

&

&

1 Like

Honestly I thought, considering my level of heat lost and where I heated vs where I measured, that it would be fine to be at 40C. Because the issue is that heat rise, the place I want evenly hot is the build plate, that is lower than the tubes.

Well, heat creep happens at the cold end of the hot end, just below the extruder. That is where a measurement would be needed. With the fan’s on, the temp distribution in the chamber should be fairly even.

&

&

Please note that it is not recommended to place the A1 inside an enclosure, especially if it’s heated.

Besides the heat creep you are experiencing, the mainboard and PSU inside the base can overheat leading to either print failures or damage over time to the printer.

To solve the warping issue, ensure your plate is washed well with warm water and detergent to eliminate any debris, and use “brim ears” in Studio, placed on the corners of the model.

1 Like

I have tried the brim ear and full brim and it solves nothing at all.

And I understand the heat issues for the components but that’s why I was limiting to probable inside a house temperature.

And an enclosure prevents air draft.