I’ve become adept at extracting and disassembling the extruder due to the large number of clogs I’m experiencing. this is usually during multi-hour prints when a failure is particularly galling. by the time I get it apart, the extruder enclosure is still very hot. so clearly the filament is becoming too ductile way before it enters the melt zone. the globs are wrapped around the gear. this seems like an extruder design issue. obviously, the chamber is enclosed and heat is building up. has anyone had the same issue and come up with a strategy to keep the extruder gear path cooler for long prints?

Which type of filament? If PLA are you leaving the door open?

Certainly laid my hands on the extruder a bunch and not even warm

I’ve printed some 8 hour prints and I just a couple of days ago swapped out the plastic extruder gear for metal throughout and I can say that the all of the stock parts were in pristine condition. Definitely no throw-away parts. The plastic drive gears were fine, as were the gears that contact the filament.

You do anything with speed settings or temperature settings?

The way the extruder is built, if it were getting hot, all the grease will liquify and pool at bottom so have you seen that?

Sometime I have to print a lot in glow PLA, which is a heat creep nightmare once you need to slow down for details or lots of retractions.

The usual ‘fixes’ won’t work for me as this time of the year I have no issues reaching 30 degrees in the house - Celsius that is.

Even on 20 degree days the heat creep happens with the door and lid wide open.

I experimented a bit with a new front housing and a larger (air) volume blower motors rather than the flimsy fan.

Worked a treat initially until I found out there isn’t enough space left when printing things all the way to the right on the plate.

Now trying to make the design smaller and with the blower fan embedded rather than mounted onto the right side.

By worked I mean I did not experience constant blocks during test prints that soften the filament too much in the past.

It still won’t address the general over-heating issue of the hotend’s upper parts.

For the new version I want the fan, just one fan, on the front of the housing module.

Sadly I am only good at basic designs and struggle badly organic shapes.

Makes it very time consuming to design matching air channels to pull in chamber air to go through the cold end and the rest of the head housing to keep things cool.

Initial checks with my little FLIR camera revealed that even with the bed at just 55 degrees it is very hard to get any real cooling going in the print head.

I came to the realisation that while PLA can be handled with a few modifications or by leaving the printer open in a cool enough room the same can’t be said for other filaments.

A lot of my issues vanished with the E3D hotend I installed by I won’t that for filled filaments as it ruins the inner coating too fast.

Hoping to get the time for it this summer I want to add another hose going into the printer.

An air line from a small airbrush compressor feeding pre-cooled air into a slim box over the hotend fan.

the remaining air is split to cool the extruder a bit as there the heat creep often means a total block right after the transport wheels.

In case it works out I will report back with plans and instructions.

I’d actually been giving this some thought. I tried doing PLA support on a PETG print and it gave me fits. The PLA would load in a printhead that had been printing PETG, in a build chamber that had been printing PETG, with predictable results.

I was thinking I could force air down the tube the filament follows to get to the print head. It wouldn’t be a lot of air, but it would be cool air, and it’d vent right into the area where the filament usually blobs-out and jams the extruder.

Something like an aquarium aerator pump would probably do the trick nicely… mated to a Y fitting right at the back of the machine.

No chance to get any meaningful amounts of air through the same tube with the filament inside.

I was thinking in the area of a thin and very flexible fuel hose, as for law movers and such.

Only issue I encountered last night was my calculator complaining.

My little airbrush compressor has a much higher airflow than my aquarium air pumps but still only about 7% of the air volume just the side fan for the hotend delivers.

At least according to my simple fill the bag with air test…

Means that even if this air would be much cooler than the chamber air it would still not be enough to cool things.

We would need a pump, not a compressor to get a matching or better airflow ![]()

Of course I totally ignored math, common sense and logic to try anyway ![]()

I cut the hose in half after plugging the end so the air would go through the hotend fins from the back.

Like a crossflow to the build in fan.

To my surprise the hotend cooled down from 230 to 100 about 8 sec faster than with just the fan.

Nowhere near enough to make a dint but at least it confirms that better/more cooling helps.

Then I thought that so far my main issue was with the extruder blocking up badly while removing the filament from the hotend was childs play by comparison.

Got the glow filament out, changed to the hardened steel hotend and started a dreadful lithopane print that always failed with a blocked extruder.

This time though I wedged the hose in there so the air would go through the area after the transport wheels - more or less.

Made it further than usual but the print still failed once my hose somehow ended in the void with the filament to cause a nightmare jam LOL

Put it all back together, grabbed a beer and started thinking.

Grabbed another beer once the thinking did not come up with conclusions to then go through some pics of my old printers in action…

What’s the main difference between those that simply never jammed up and those that did?

The former were slow, had rather huge hotends by modern standards and were fully open around them, with the fan screwed right onto the cooling block.

Those sometimes struggling with certain filaments and too many retractions had either much smaller (shorter) hotends or the head with an enclosure around.

The most important difference though was or is that all the well performing ones had a teflon liner between extruder and hotend in a housing that wouldn’t allow the filament to bend away or get compressed - too tiny gaps.

IMHO we have two problems making each other worse:

An enclosed print head that gets cooled by the hot air inside the print chamber.

A too short neck on our hotends with a too inefficient heat break and heat sink sitting right over the hot extruder with no isolation.

The front fan blows into the head, same as the hotend fan, which relies on those tiny holes to breathe.

The entire design works as advertised but is not optimised for air flow and certainly no one considered that PLA isn’t the only filament out there - we can’t always leave the door and lid open…

The higher the chamber temp or the closer to the plate the head still is the more cooling issues we face.

Imagine the chamber going to over 70 degrees - how is there any cooling happening where it matters…

Since I use the E3D my PLA problems disappeared together with a lot of other issues.

But I can’t replace those costly things on a regular base to print abrasive filaments with them.

And a jam with those is a total pain and can mean having to dispose of the hotend.

Will do some more thinking and tinkering …

The tube ID is 2.5mm and the filament is only 1.75. So the tube is almost 50% bigger than the filament. Air will definitely flow. And I’m not convinced very much air is required at all.

The biggest benefit might be to the filament in the tube itself. All the time it’s slowly feeding through the tube, it’s pre-heating. The filament doesn’t jam immediately when it’s loaded, the printer has to run for a bit. The temp of the area of the “infeed” at the top of the extruder probably doesn’t change much when new filament is loaded. The filament has to get hot enough to buckle, but it doesn’t stay in this area very long. I think it might actually the “preheat” that’s the primary issue. If so, even a little airflow will remove some heat. And a few degrees of heat removal could be all it’d take…

Interesting idea but the heat creep in the filament starts from the bottom.

The tube only goes in the top while the extruder jam happens below the transport wheels.

But if it works a bit it is still worth considering.

OP hasn’t responded. What a wonder.

I’ve been throwing filament through theh same extruder for over a year now and have never had it heat up. IF it is it’s heat creep and cooling the extruder isn’t the problem.

Open the door and top. If you’re in a hotter enviorment consider a fan or moving.

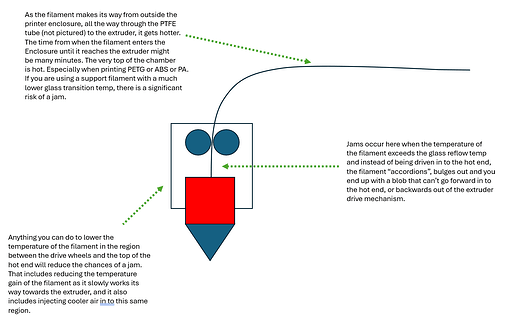

My thinking on this… The filament is being “preheated” while it traverses the PTFE tube at the top of the build chamber. Then it enters the area between the extruder drive wheel and hot end. If it gets too hot there, it splooges out and you get a jam. If the filament is cooler going in to this area, it will be less likely to gain enough heat to get above its glass transition temp and splooge out. ![]()

If the air being pushed down the tube was refrigerated it’d probably work even better.

Anything that drives the temperature of the filament down before it enters the critical area of the extruder ought to help reduce or even eliminate this type of extruder jam.

The chamber is not hot enough to transfer enough heat to soften the material as it goes through the ptfe.

Jams are either filament that isn’t 1.75mm, wet, old, a combination of all these, or the door is closed and heat creep from the nozzle is causing a jam at the top of the nozzle. Chamber temp will only contribute if the other conditions are present, it won’t cause a jam. The jam will happen before the chamber temp can interfere

Think about this a bit… if the filament enters the area where the heat creep can cause a jam, and its temperature is just a few degrees below its glass transition temp (the temperature at which it softens), it takes very little additional heat coming off the hot end to melt it. Maybe just a few seconds exposure to the higher temperature in this area would be all it’d take.

If on the other hand the filament was cooled (say to absolute zero for the sake of argument, make pretend it’d still be flexible and that the hot end could deal with it in spite of how cold it is ![]() ) it would not remain in the jam area long enough to absorb enough heat to soften.

) it would not remain in the jam area long enough to absorb enough heat to soften.

The cooler the filament is going in to the extruder, the longer it needs to “linger” in the area between the drive wheel and input to the hot end to absorb enough heat to get hot enough to melt/jam. Cooling the filament would almost certainly help.

The glass transition temperature of polylactic acid (PLA) is typically between 60–65°C (149–153°F)

I’ve printed ABS, ASA, PA-6 (somewhat successfully). All of these need a chamber temp of at least 60.

I have a thermometer inside, Only a few times have I hit 60. This is while printing ASA with the doors and top closed, the bed at 100, the nozzle at 280Ish, with the various things I’ve done to keep temp in. It still fluctuates while printing.

I would wager that there’s no way the chamber is getting to 60 with PLA whos bed is 50, nozzle 220, and lid and door open, hell just the lid open.

I don’t want to argue, but I believe in science and logic. The chamber is not hot enough to put PLA at it’s glass point as it goes from the back of the printer to the extruder through the PTFE. Just not happening.

Like I said, the nozzle can heat to the top of the heatbreak and cause sofening there, which will lead to a jam in the extruder. A jam above the extruder or at the entrance is not going to be heat. If it were there would be other damage to the hot end.

You don’t understand the problem.

Try printing PETG using PLA for support material.

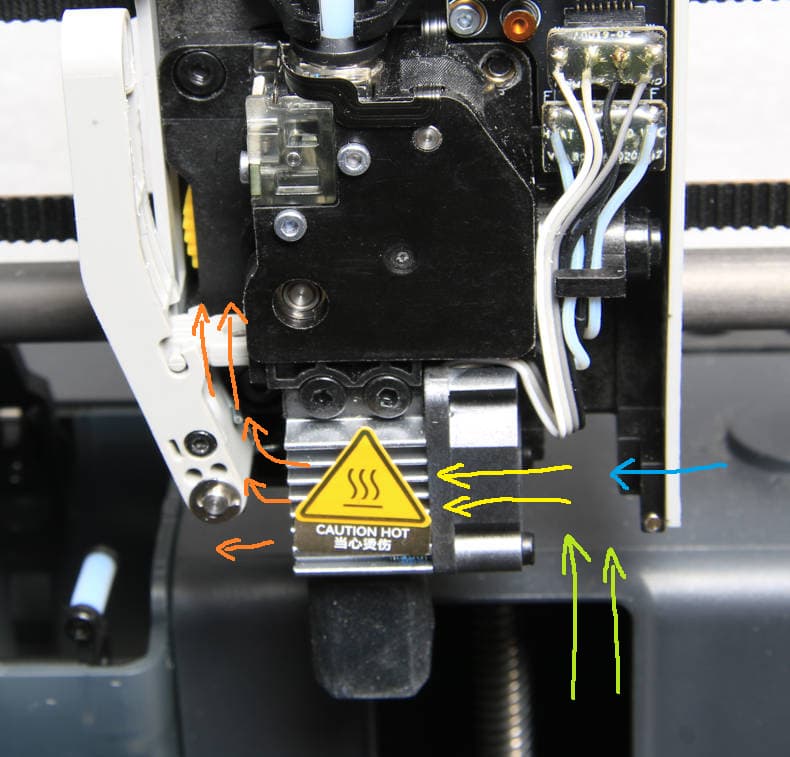

This is what I think

These vent holes are too small and it restricts air flow quite a bit

From what I can see, it just takes the heat away from hotend and dump a bit of heat into extruder.

Because of this, chamber temp can be 40C but inside the toolhead could be 10-15C higher

Explain how the printer get’s to the point where the petg print temp raises the internal temp so high that it causes the pla to hit glass point enroute to the extruder.

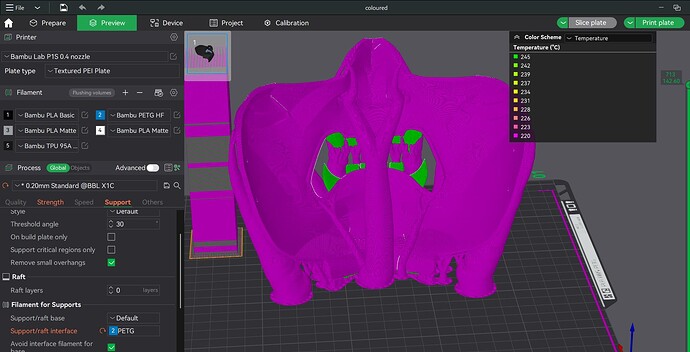

As you can see in the above image PETG won’t get over 245. About 20 above the temp for PLA, but only for a few seconds as it’s just for the support interface layer. This isn’t for every layer, it’s for the interface layer.

The temp is never high enough to raise the chamber temp above 40 max. The extruder is not getting hot enough to push PLA to the glass point. If anything is heating would be the nozzle past the heat break, which would cause a jam at the most near the top of the nozzle.

The vent holes have notihng tyo do with it, at least in the description the OP has stated. The fan is moving air from the chamber so anything being blown is at chamber temp or a little above. IF this were a problem than others would be jamming all the time on PLA alone, or PETG.

You can stick to your guns if you want. Telling me I don’t understand is a bit much given you still haven’t given any instance where the chamber can heat beyond the glass point and heat the ptfe entering the printer, softening the PLA.I do print with support materials quite a bit, more than just PETG.

Given the actual time spent printing the PETG for support, it shouldn’t raise the internal temp beyond 1-5 for a very short period.

If you’re jaming before the extruder look at PTFE wear, quality of the filament, moisture content, or if you’re extruder needs cleaning.

If you’re jamming at the nozzle check above and open the door and top. Also check your cooling.

Once again, don’t come at someone saying they don’t understand the problem if you don’t KNOW the problem yourself, or the person you’re pointing that at.

Now I’ve said all there is to say. If you don’t choose to believe me, have fun with your jams.

You’re still not getting it. Go re-read my example again. I’m not saying the filament melts in the PTFE tube. That’d be stupid.

I’m saying the filament gets pre-heated by the chamber temp on it’s way through that tube to the extruder (which is why, in part, lifting the chamber lid reduces the odds of a jam - the PTFE tube isn’t sitting in as-hot air).

The hotter the filament gets from the chamber, the less additional heat needs to be added in the area above the hot end to generate a blockage. So if the filament is cooler when it enters the extruder, it will require more heat in this area to get the filament hot enough to soften and cause a blockage.

So pumping cooler outside air down the PTFE tube will keep the filament cooler during its traversal of the tube, requiring a longer “exposure time” to the heat above the hot-end before it can melt. If the exposure time is long enough, the filament feed rate moves the filament faster than it can reach that critical temperature and you don’t get a jam anymore.

Also, the air that exits the PTFE tube at the extruder will, to some extent anyway, be discharged in to this area where heating leads to jams. That would remove at least some of the heat from this area, too.

This idea would have to make a difference. The only question is whether or not it’d make enough of a difference and that’d have to be answered empirically.

NO IT DOESN’T get “preheated”.

Read what I wrote. The use of PETG isn’t enough to raise the temps in the chamber or around the extruder to cause what you’re describing. PERIOD.

I can’t believe this is a thing. Look, let’s take PETG being used as a support material. Let me play along that this is what is causing enough temp incerase to “raise the temp” enough to affect the pla.

When you use PETG as a support material the nozzle moves, heat’s 20c higher, then pushes the PETG to the extruder. For a short time (depending on the amount of supports are interfacing with the PLA on that layer) the machine prints PETG. Then it stops, moves to purge. While purging it’s still at PETG temp. Remember is is only 20 above PLA. Once purged the printer drops temp to PLA temp, loads and hits the tower. It then prints longer than it did with the PETG. There’s simply not enough time for the temp in the chamber to have an effect on the filament of either.

You’re saying that the PLA is raised as it hits the extruder softened by it’s trip from the back to the extuder. NO.

The extruder is just as warm as it was when you were printing PLA after the PETG support. It just doesn’t print PETG long enough to have heat affect anything.

So in short, again. IF you are having jams in the extruder it is from heat creep from the nozzle, wet filament, or filament that is not at 1.75mm diameter.

There are two much larger holes on the right side, plus a very large opening on the top of the cover and another around the opening for the filament cutter. Air flow is not a problem.

For about two years, a great many printers have produced beautiful prints, without clogs, in many different materials, while using covers with those exact vent holes.

If you are printing with PLA, PETG, or TPU, open the door, raise the top, as Bambu recommends. It’s unlikely the chamber will reach 40°C.

What I’m saying seems so obvious to me, I have to think your continued disagreement with me is due to me not doing an effective job of explaining. So here’s a picture I just spent 30 seconds making in Powerpoint in an attempt to remedy that. Which may not be all that effective, but it’s going to be my final shot. ![]()

When you use PETG as a support material

That may actually be the source of our disagreement. I’m not using PETG as a support material. I’m printing PETG. I’m using PLA for the support material.

To print PETG the build plate needs to be hot, the extruder needs to be hot, the chamber needs to be hot, the fans have to be off (mostly). When PLA enters that environment, unless what’s being printed gets printed fairly quickly, the PLA picks up all that latent heat that’s in the build chamber and even though the extruder temp is “PLA appropriate” the PLA still gets too hot and collapses in the extruder and the extruder jams.

I can say with a fairly high degree of confidence that it’s the temperature of the filament as it enters the extruder assembly from the PTFE tube that is what matters. If it was only the heat in the extruder that caused the problem, the PLA would get there and jam instantly (or nearly so). It doesn’t. It always takes a few minutes of printing PLA in a PETG environment before it jams. That’s because that’s how long it takes the filament traversing the PTFE tube to heat up enough for the additional heat in the extruder assembly to push it over the GTT.

Printing PLA with PETG supports doesn’t exhibit the problem. Scratching my head on how I led you to conclude that was what I was saying. The chamber and extruder and build plate temps printing PLA are substantially lower than when printing PETG even if you don’t open the door and lift the lid. Of course the PETG doesn’t care about the PLA temps, they’re all lower than the PETG temps.