Fairly Urgent! Printing a poop basket for my X1 Carbon and I ran out of my filament 58% into a print on Tuesday. I didn’t have another spool so I ordered one but it won’t be delivered until next wed. The print is obviously on pause but the heat and fans are still running. What is my best course of action to ensure that I don’t ruin the printer while waiting on the filament to be delivered? Also can I stop the print, pull out the plate print something else and resume the original print later?

TIA

Chad

LOL I also ran out of filament printing a poop basket and left it on pause for a week waiting for new filament. It should be fine. You will likely get a small layer shift where it is paused.

I started weighing my filament with an inexpensive digital scale and recording the weight on the spool. I did this mainly so I could see if it contained moisture, checking it right out of the box, after drying, and before and after any prints. If it gains weight in storage I know it has absorbed moisture and can dry it before I waste time and material on a bad print.

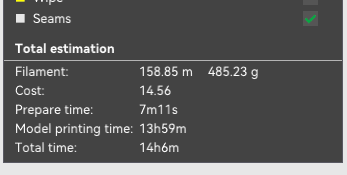

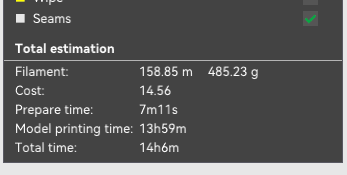

One other benefit is that I know how roughly how many grams of filament have been used and how much remains on each spool. After slicing a project, Studio provides an estimate of the filament needed that I can use to avoid running out midway.

(That estimate was for a fairly large poop chute. I decided a squarish juice bottle with the top cut off would work just fine and the cost savings bought some new filament)

Honestly, I would just stop the print if I’m not able to resume a print within 6 hrs after there’s an error. I think it’s a waste of energy to keep the bed heated, etc.

Some options I would consider doing:

- print a whole new one, since filament isn’t super expensive?

- print the remainder and glue it together. mark where it ran out of filament (at what layer), and only print that when u get the filament. If the part isn’t that thin u can glue it together.

- (not really recommended) switch the printer off and leave it till u get the new filament roll. this way you might be able to resume using power loss recovery. this however will likely result in layer shifts etc, the part will start coming loose the when the bed heat goes down

- (not really recommended) you could get away with leaving it on pause for a week. But keep in mind this whole time you’ll be using energy to keep the bed heated to ensure that the part is still in place, but there also no guarantee that there won’t be layer shifts. Also, I think most places you can probably buy filament that’s delivered ASAP. Try microcenter or Amazon if u live in the US