I have looked at the specs of the printer. It states 1320w at 120v wich would result giving 11amps at max power… ive looked at the cable and it says 10amp max the power cable. shouldnt there be a gap range on that cable like at least 15% or so ? and why is it 11amps max power and the cable written 10amp on it max ?

10% over probably isn’t going to be a risk since the rating of the cord has margin built in to it, possibly as much as 20% (=best practice). It’ll just be a little warmer than ideal. Probably.

But just the same, it’s hard to see how they could have got UL/CSA approval if the power cord isn’t rated properly for the load, margin or no…

I think I remember someone posting they actually measured 11A on their machine.

Check the AWG on this cable, it should be written or stamped on it. I’ve just noticed that on mine (EU specs), it’s stamped 3x0.75mm2 which should be absolute max of 10A but the max Amps writen on the cable is 16A!!!

It’s a standard appliance cord. Buy the ideal length in 14ga. The cable looks like its 18ga.

The 10 amp rating is for continuous power.

Just a minor heads up - might not want to run that power cord under carpets, rug, or in any small raceways to prevent overheating.

I’d absolutely replace the cord, though. It sounds like the only thing keeping the cord from being overloaded is relying on the printer regulating temperature to keep the average power below the stock cord rating. When doing initial heating it’s probably in an overloaded situation, though.

The stock cord may be ok, but manufacturers running up to the limits on what components can carry is dangerous. Looking at you, nvidia.

For this common IEC power plug/cord, 10A is always the IEC amperage rating, but that’s different from the actual limit. In North America, UL/CSA certifies these C13/C14 up to 15A.

So, the cord shows the generic IEC rating by default. That’s typical. And it can run more than 10A, though it’s a good idea to use at least 16awg for this load (1.5mm2).

You’d use the same cord on a PC with 1200W or 1500W PSU (peak rating).

TLDR, the IEC rating is very conservative.

So this is an older thread… but I’m seeing the H2D during it’s initial warmup phase overload the 1500w UPS it’s attached to…

That printer at 115vac is using well over 10A on a 15A circuit.

What I’m planning doing is installing a transfer switch and running the printer on the 15A wall circuit and using the UPS as a backup in case of a power outage. (Putting the transfer switch on the wall circuit as the primary, and the UPS as the secondary source - which will generally cut out the overload condition.

I also used a 12ga server power cord to prevent the cord from getting to hot, and a 10ga 12ft extension cord to get the power to the H2D for the short run across the room.

The H2D consumes a max of 1600w when heating, not continuous. 13.3 amps in the US. In my home, most of the receptacles are on a 15amp circuit, which includes the work area I am running my printers.

I hired an electrician to install 2 - 20a circuits to my work area. Each circuit has a dedicated 4-plug outlet. I currently have an H2D, X1C, A1 and mini on those circuits, plus filament dryers. The printers next to each other look like a damn bambu lab advertisement.

For extension cords I got 12awg.

Cost was around $1000 USD not including extension cords.

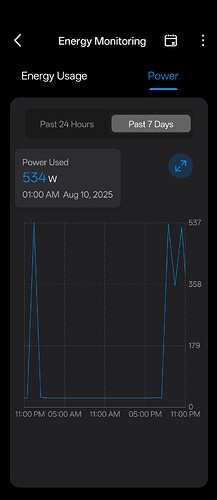

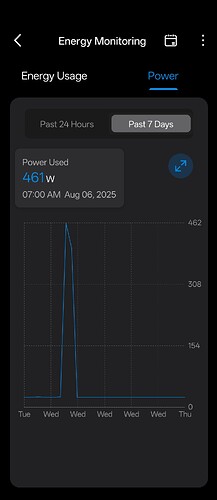

My plugs are showing max of 564(edit: 534)watts for one machine startup, and they quickly drop down after initial warm up(either). That way, I’m able to start up a 2nd print on my 2nd machine after initial warmup and actual printing starts… Typically, I just wait half an hour, and begin the printing. These are all ABS prints: 115 on the bed, 65 on the chamber and 260 on the hotend. It drops down to 461 watts, if I’m doing default Bambu profile of 90 on the bed, 65 on the chamber, and 260 on the hotend…

I am new to monitoring the electricity “game”, but it certainly “does” verify what I’ve been experiencing since having 1 H2D and 2P1S units: I can run them all day, as long as I don’t “start them all at the same time”…

I also am monitoring the dryers, to add in those to my calculations…

I would NEVER run this printer on a UPS!

Most UPS’s on the market are junk and will never perform to rated specifications for the most part!

I have four AMS HT units, three AMS2 Pro units, and one H2D that I monitor. At most, the power consumption reached around 1,200 W for about a second during heat-up, after which it quickly dropped. This was with all AMS HT and AMS2 Pro units in heating mode, and the H2D set to a 120 °C heat bed and 65 °C chamber temperature.

Based on this, I don’t agree with those claiming the machine consistently draws over 1,000 W. However, I’m not dismissing their numbers entirely — they might be measuring additional loads through their setup that I’m not capturing. In my case, even when running all heaters at maximum, I can only sustain around 1,200 W for a few seconds at most.

In my case it’s an industrial UPS that is made for heavy workloads, not a common Amazon cheap unit, so more of a 15A rack unit.

I’m going to put an APC transfer switch with a network card and load reporting on it to check this later today. This way we’ll get a proper accounting of what’s happening. (H2D Laser Edition, 2 AMS 2 Pros, 1 AMS HT)

Well, when I posted this, and even prior, I was really hesitant. I don’t see where it’s drawing that 1600, or 2100 watts of power, from the unit “by itself”… Like I said, I’m new to power monitoring, and I have the AMS units, each one, on a separate plug… I mean you have to draw a lot of power to pull 1600 to 2100 watts. And while I get why Bambu might say that, I know for “me”, it scared me. But they’ve got to CYA, as a business…

I cannot overestimate that I run RC helicopters. The big 700 machines that run on 12 and 14 lipo cells. The milliamps right now, are ranging between 5000 and 10000 per each 6 or 7 cell pack. I’m pumping between 5 and 10 amps to charge 1 pack, and that’s at the slowest settings for that one pack. I have 3 700 sized machines. Each machine, I currently have 3 packs. So, with me charging 1 “full charge”, I shouldn’t be able to run 1 of my printers on the same circuit. But I can… Easily… That’s my thought process, and it’s only mine. But we(myself, my wife and dog), run a very electrical intensive home. I think most people do now…

And I have done IT work the majority of my career. I’ve dealt with servers, desktops, laptops, pulling cable, yada, yada… I don’t see where these things are pulling that much voltage.

But… I have yet to check my AMS2 plugs… It could be in all honestly, that when you’re printing, but trying to dry an AMS, that the heater in the AMS unit in pulling a considerable amount of power… Not saying that it is, or isn’t. Again, I haven’t checked those yet… But, I know from my aquarium days, when I had my 180(which was actually 240 gallons total system volume), I ran 2 1000 Watt heaters in the sump… Now when they did kick on, you really could tell… But those ramped up instantly… My point is, could be the heaters in the AMS units pulling the bulk of the power… Could be…

My X1 Carbon is in standby with one AMS HT running a 24-hour dry cycle at 85 °C, currently drawing 15 W.

My H2D, which is actively printing with full exhaust fans running and an 80 °C heat bed, draws 319 W — and in that setup, one AMS HT is also running at 85 °C during printing.

So, either some people are exaggerating claims of a sustained 1,300–1,600 W draw, or they are measuring something I’m not.

What material you printing? It helps to know what wattage people are using per type of material. At least it does for me and my curiosity…

And lol, I’m trying to not say “over exaggerating”… I would simply like to see graphs or something. Anyone can say anything(including myself). But it worried me so much, because this is so much more than just printing. You’re talking about a potential fire hazard…

For me, with the 2 machines and AMS units, I am just not, and haven’t thankfully seen it… Again, I get why Bambu said it. I truly do…

Right now, I have a print running PLA Basic and TPU 90A simultaneously. Normally, I work with ASA, PAHT-CF, PPA-CF, PET-CF, and several other filaments. My residual-current device is extremely sensitive and would have tripped immediately if there had been any electrical fault

I brought home an APC transfer switch, with one side plugged into the 15A wall outlet and the other to the 1500W APC (nee Schider [sp]) UPS (not a desktop UPS).

I’m configuring the network card for the switch’s reporting now, and will grab some telemetry as I get going. The UPS overloads whenever the heatbed is initially warming up, and then once it reaches temp the overload condition stops.

More when I have it…

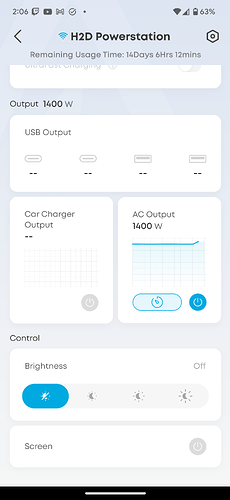

The only time you should see those numbers is during warmup. Here’s 1400W heating the bed, chamber, and one nozzle

What is the power cord length? 6 foot? In the US, standard 18 gauge is approved for 15 amp load for this length. zero issues. But it should be a 16 gauge for 15 amps, 10 amps is fine at 18 gauge. If I had to use an extension cord, go with 16 g up to 25ft or 14 if much longer. No fire issue.

Dang, I’m glad I do my own work. That isn’t cheap at all.