Hi folks,

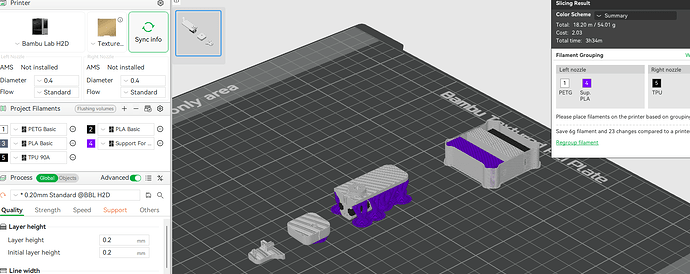

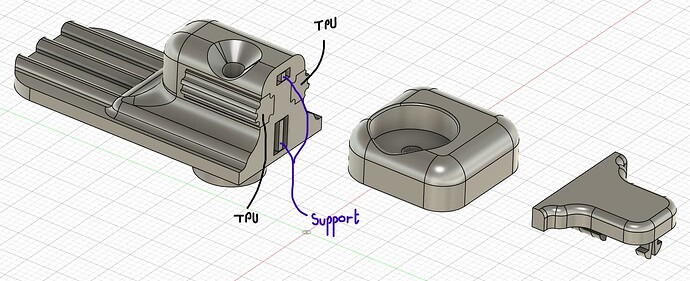

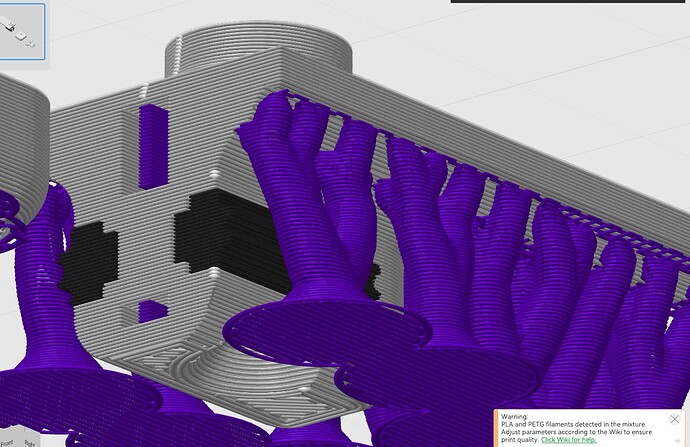

Anxiously awaiting the arrival of my H2D.  New to 3d printing and I’m planning the attached to be my first print. Its 1 of 10 door clips for my back door screen.

New to 3d printing and I’m planning the attached to be my first print. Its 1 of 10 door clips for my back door screen.

Because I like a challenge…its multi-material with Bambu PETG, Bambu TPU 85A/90A and Bambu Support for PETG…which may go horribly wrong since I have no idea what I’m doing!  Need to figure out how to do the TPU through the right nozzle and everything else through the left with AMS…but thats a future me problem…

Need to figure out how to do the TPU through the right nozzle and everything else through the left with AMS…but thats a future me problem…

Notes:

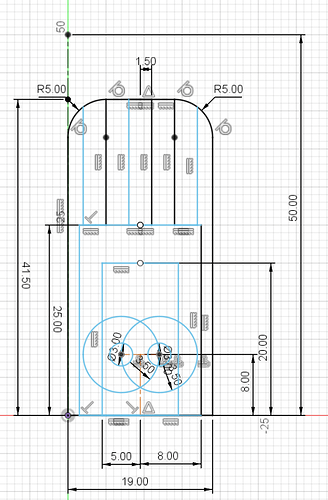

- I’d love to print it with a 2mm nozzle because its so small, but I guess 4mm is needed to facilitate the TPU grips.

- I have oriented it so the faces where I want a nice finish are on the bed, and the bolt holes dont need support.

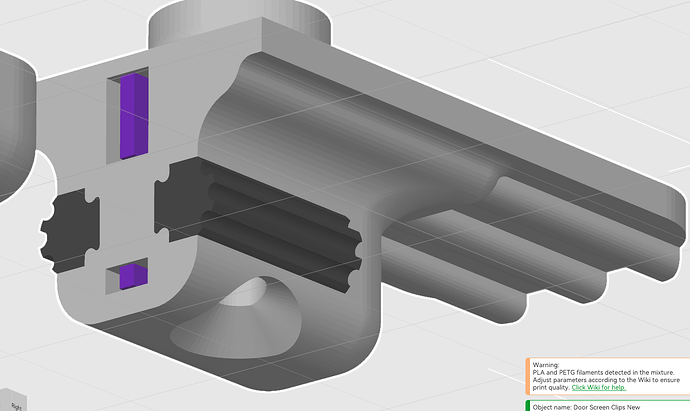

- There are two tiny vertical supports in the back side which I designed in manually to remove with a needlenose pliers, I think this will be easier than removing the default support from these tiny slots.

- Bambu slicer settings are default - apart from ignoring the prompt to optimise the support with 0 gap etc. when TPU is detected. Because most of the areas needing support are not TPU. Just a guess on my part.

Anyway, its looking like 3hr 49min and 2.18 cost for a print and I’m just trying to align my expectations.

Does this seem about right? What would you do to reduce the time/optimise the print?

Thanks for any advice!

1 Like

As I always say when someone asks about optimization, it’s better if we can get the project file.

Is it possible that you can share the model?

But as a start, if planning to do the grip in TPU 85A you must use 0.6 nozzle or hack your printing process. TPU 85A is not available for 0.2 or 0.4 nozzles.

1 Like

No problem, thanks. Here it is.

Door Screen Clips New BS.3mf (293.7 KB)

Note: When you open it asks if you want to use mm. Select 'no.

I think .6mm will be too big for a nice finish on such a small part, but maybe I hsould print the grips separately anyway. Thanks for the advice.

Either my Studio is interpreting the project incorrectly—when I open it, every part is set to PETG Basic.

I assume you want the grips in TPU (with a defined Shore hardness) and the rest in another material.

I’d stick to PETG + TPU plus the appropriate support material. PLA does not bond reliably to PETG, so if you mix those two, account for that in the design to keep the final part durable (e.g., use mechanical interlocks or avoid placing the interface in tension).

Also, printing TPU with a 0.2 mm nozzle is more trouble than it’s worth—expect clogs, unstable flow, and poor layer fusion. Use 0.4 mm for TPU unless there’s a hard requirement for 0.2 mm.

I’ll be away from my desk for a couple of hours; if no one else has replied by then, I’ll pick this up and continue.

1 Like

Siraya Tech TPU Air—and other variable-Shore (“varishore”) filaments—are fully compatible with 0.4 mm nozzles, should you choose that size.

1 Like

Strange, I painted the TPU and selected the support material before saving. When I reopen it the 3 are already specified. But what you said is correct, grips in TPU.

Thanks, I came across that a few days ago online and it looks really good. But probably a bridge too far for my first shot, with a lot of variables already to manage.

Forgot to mention, I have a roll of Creality PETG filament and a roll of Bambu PETG HF on the way with the HF nozzles. Not sure if that makes any difference, setting the left extruder to HF in the slicer doesnt result in any increase in print speed.

![]() New to 3d printing and I’m planning the attached to be my first print. Its 1 of 10 door clips for my back door screen.

New to 3d printing and I’m planning the attached to be my first print. Its 1 of 10 door clips for my back door screen.![]() Need to figure out how to do the TPU through the right nozzle and everything else through the left with AMS…but thats a future me problem…

Need to figure out how to do the TPU through the right nozzle and everything else through the left with AMS…but thats a future me problem…![]()

![]()