Hi All,

I am guessing this is fairly common and when searching for first layer problems done the basic generic troubleshooting.

Printer was originally on the same stand as my old Anycubic Mega S, to the floor, in case the table was causing a wobble.

Washed the PLA build plate with dish soap and cleaned with a microfiber cloth.

run recalibration multiple times, check out the wiki links for maintenance on the lead screws and bed leveling.

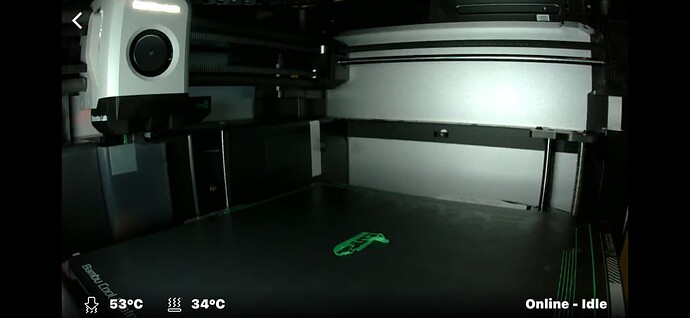

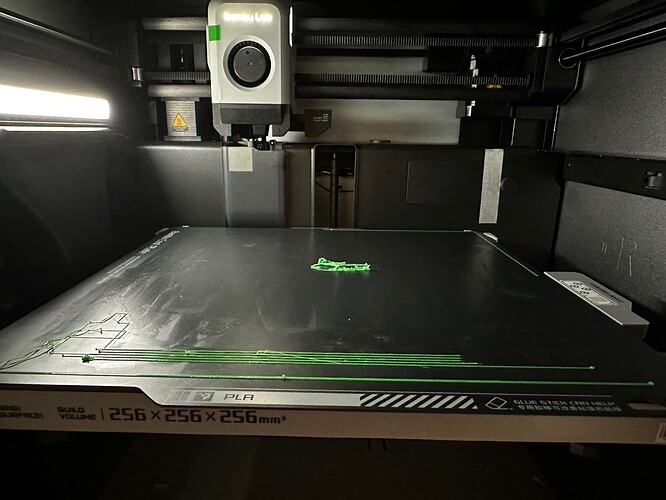

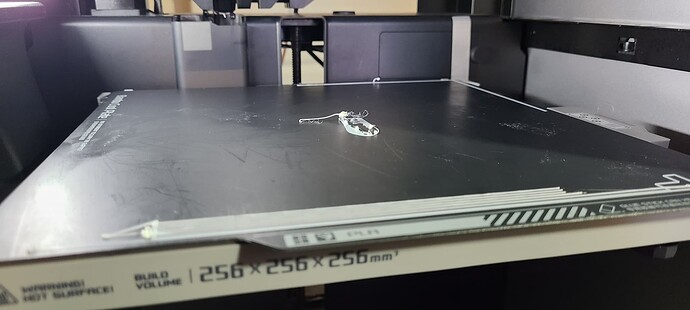

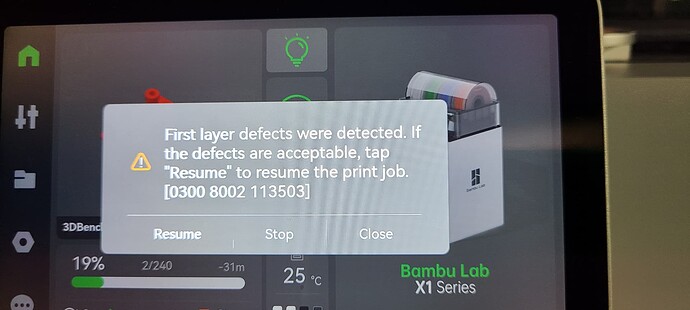

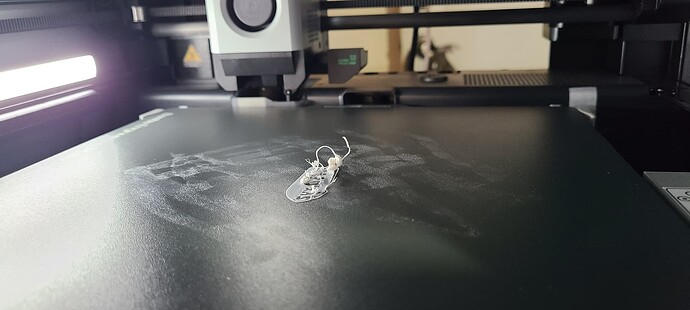

This are the images of the it failing on the first layer.

As I finish writing this and go to test with a different generic filament, I have iht an error with unloading the bambu PLA filament, when doing this the roll seems to be bouncing up and down and struggling to retract…

When taking a look inside I have noticed that inside the AMS there is a slight runner/ridge that the filament spool edge seems to slot into this groove…

So am I now going to try printing with the spool in the runner inside the AMS.

[Edit1] I was going to delete this post before even posting it but in all the videos and guides I watched before purchasing I have never seen this mentioned. it might not effect anything and not fix anything but going to leave it here

[Edit2] so it still looked like a fairly poor first layer but it hasn’t triggered the AI first level error.

and has completed.

So first layer was fairly poor, but it continued anyway and the rest looks pretty good from my brief experience with the Anycubic i3

[Edit3]

OK, it looks like at the end of the print, the printer tried to unload the filament back into the AMS, as it was starting to roll back the spool, noticed that the spool filament was coming out but that the spool wasn’t spinning to reel it back onto the holder…

it then started to try and activate a second spool in the AMS, and started to wind that in and then back out. Not quite sure what is happening but it looks like the issue is more likely filament feeding related.