Welcome to the community.

The short answer is: No, there is no CAD software that makes this easy - and believe me, I’ve been searching for decades. My interest dates back to 1997 when I first used Pro/ENGINEER (now Creo). Back then, I was focused on converting CAD files for raytraced rendering in marketing materials, not engineering. Even after all these years, there’s still no “great” solution - I get by using a mix of online converters and desktop tools. If anyone knows of a better method, I’m all ears.

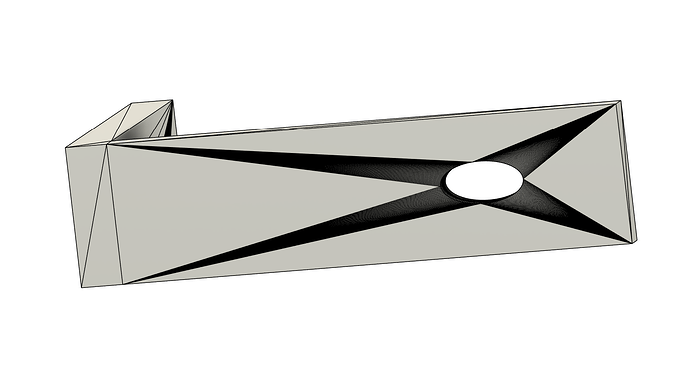

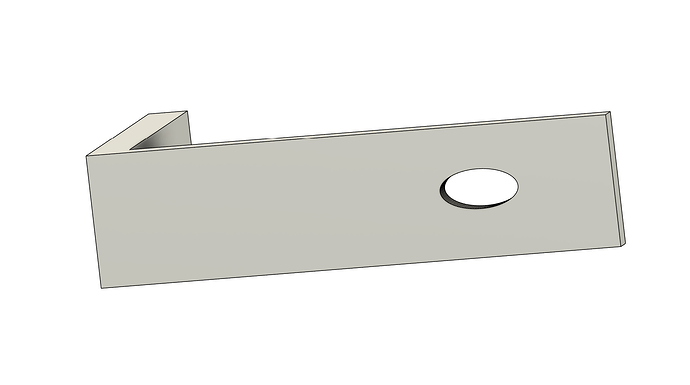

You already understand the difference between STEP and STL meshes, so here’s the core issue: only one CAD program comes close to recovering arcs and circles from a mesh without a multi-thousand-dollar license, and even then, it’s far from perfect. Fusion 360’s paid version includes a “Prismatic” feature that attempts this, but at $680/year, is it worth it for a single feature? Autodesk’s Meshmixer can accomplish similar mesh cleanup and face grouping for free, though it doesn’t create parametric geometry.

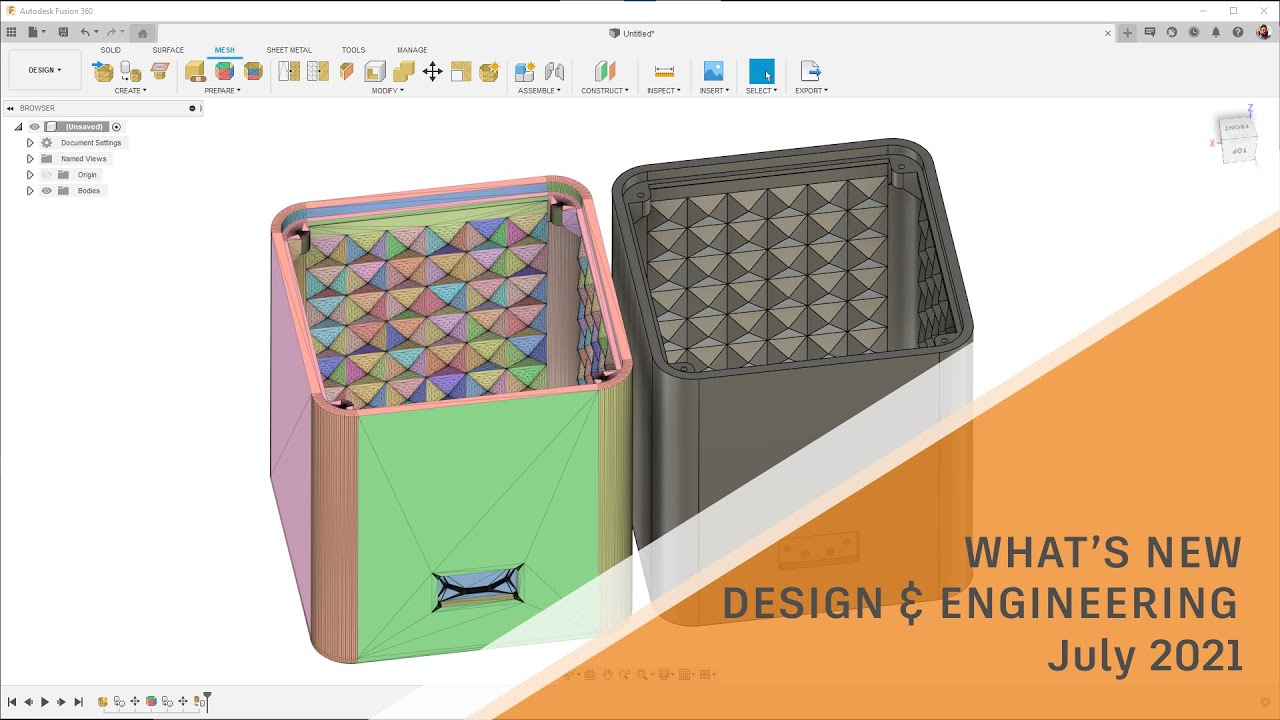

For a demo of what Autodesk claims Prismatic can do, check out their July 2021 update at the 3:50 mark. If it truly works that well, it’s impressive - but I’m not spending $680/year for something I only occasionally need and can partially do elsewhere. If cost isn’t a concern, try it and let us know if it delivers:

Prismatic essentially converts a mesh into editable face groups, but that’s just step one - you still need to redraw geometry to make it parametric and scalable. Shortcuts exist, but they just shift where you spend the effort.

Bottom line: there is no “best” solution.

I use both Fusion 360 and Onshape, starting with Onshape and switching to Fusion 360 only when necessary. FreeCAD 1.0 also finally released in 2024 after 20+ years of development. Its STL-to-STEP conversion outperforms the others but comes with a steep learning curve that’s worth it if you’re serious about this workflow.

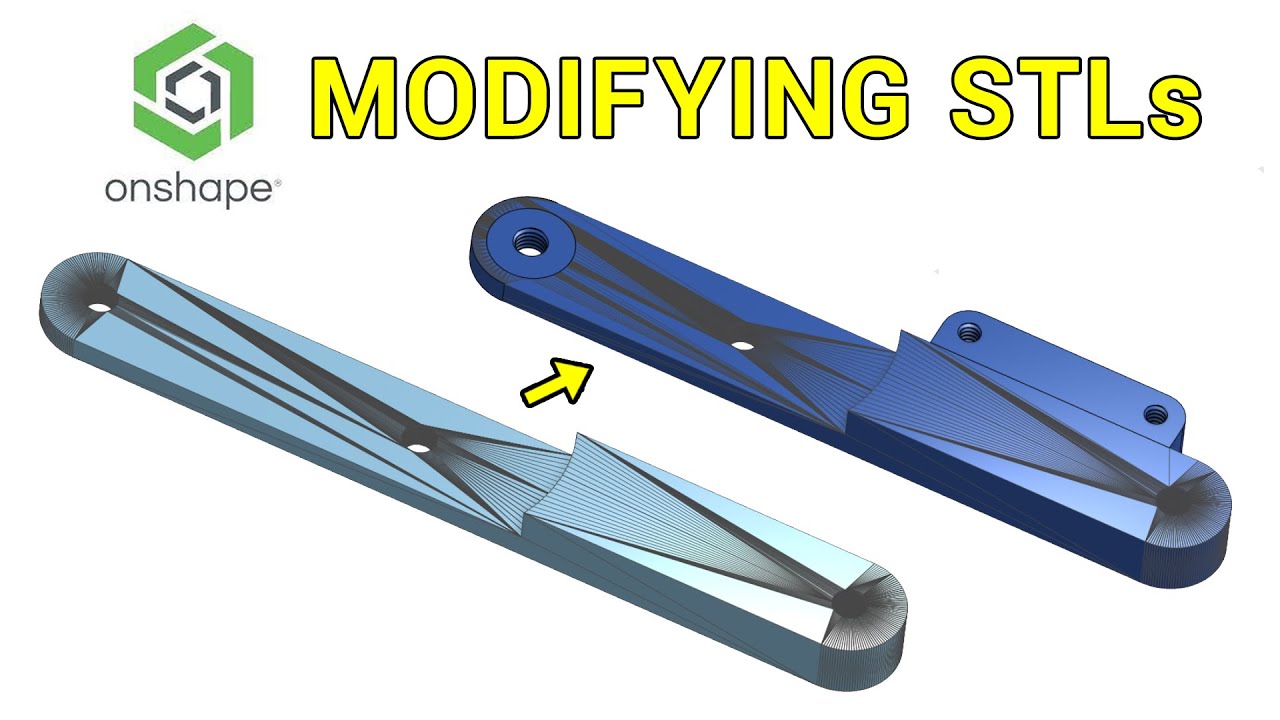

If you want a practical guide on handling STL meshes in CAD, I highly recommend this Teaching Tech video using Onshape: