Hi everyone,

I’ve been running into a frustrating alignment issue with my Bambu H2D equipped with the 40W laser module, and I’m wondering if anyone else has experienced the same thing.

When I’m doing laser fill or cut jobs using a single sheet of material, everything lines up just fine as expected. But when I try to engrave or laser-fill text or images onto pre-cut blanks (like cork coasters or tags), the final engraving ends up being offset from where it appears in Bambu Suite—usually by about 3–4 mm, often above or to the side.

This is a real issue when precision matters, especially for products where centered designs are critical for quality (e.g. coasters or tags). My current workaround is to make and use a jig with measured recesses to hold the blanks at a consistent height (9 mm in my case, with the blanks themselves being 10 mm thick), then do a few test runs and nudge the image manually in Bambu Suite to compensate. But that’s obviously not ideal, especially for repeatability.

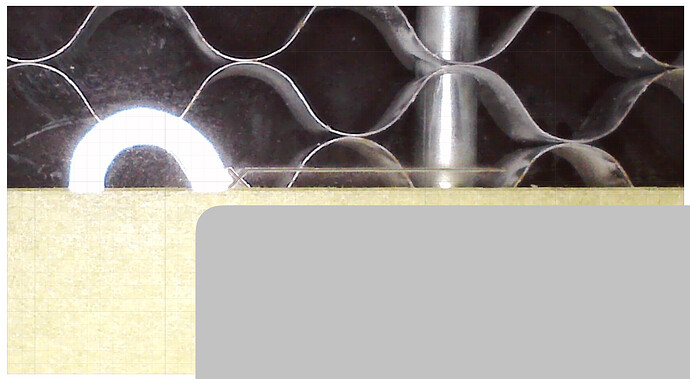

I’ve attached screenshots to show the position in Bambu Suite (pink overlay) vs the actual laser result on the cork (black image) for reference. this was after some trial and error to find the correct placement to get the imaged engraved where i wanted it.

So my questions are:

-

Has anyone else seen this kind of misalignment when working with pre-cut items?

-

Is there any way to recalibrate the bird’s eye camera?

-

Is there a way to get a live camera view from the laser module itself to check positioning?

-

Or maybe a feature I’ve missed that allows for image position offset calibration?

Any advice, tips, or confirmation that I’m not going mad would be massively appreciated! ive also raised a ticket with Bambu just for good measure.

Thanks,

Jay