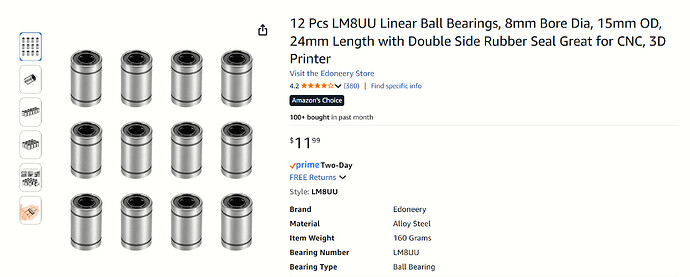

The parts you’re referencing are called 8mm linear motion bearings. They have an inner diameter of 8mm and an outer diameter of 15mm.

They are standard in 3D printing and can easily be found online. Here’s an Amazon search link:

https://www.amazon.com/s?k=8mm+slide+bearings

They range from $1–$2 each but are usually sold in bundles of 4 to 12 units. You can also do a web search for “LM8 linear ball bearings”. Any local Grainier supply or McMaster Carr would likely stock these too but expect to pay 10X the price.

Now, that’s the easy part. The real issue isn’t the bearing itself. These are friction-fit, so simply replacing them probably won’t fix the problem - you need to address the root cause.

If they’re popping out consistently, there are two common causes:

-

Contaminants inside the sleeve

Over-lubrication can cause bearings to slide out. If you’ve ever lubricated the 8mm rods, that may be why. Personally, I’ve never lubricated mine because it’s not necessary. These bearings are designed for high-speed CNC machines, and 3D printers don’t reach that level of wear. Unless it squeaks, it doesn’t need lubrication. -

Blockage in the bearing pocket

The bearings are slightly oversized and sit in a recessed pocket. If anything gets in there - such as plastic debris or if there is a printed a dust cover that was popular a while back - when the bed drops fully, the mechanism may bottom out with a grinding sound. That can push the bearings out.

BTW: Here is the wiki video on how to remedy it but it sounds like you are already past that.

There is a related discussion on this a while back that may provide other ideas.