Apologies in advance for the long post! Hopefully, I’ve explained everything clearly but if you have any questions, please ask and I’ll answer as best I can.

I have 4 Bambu Lab P1S 3D printers that I bought just over a year ago and I’m at my wits end…I’m losing hot ends like there’s no tomorrow and I am at a loss for why. I’ve lost 8 within 2 weeks. The machines printed great for the first few months but here lately, they are ghost printing and clogging the hot ends on a regular basis. This is primarily with PLA filament. I have used Comgrow PETG a couple of times and do not remember having any issues.

PLA filament brands I’ve used are Kingroon, Anycubic, Bambu, Sunlu, eSun, Elegoo, Comgrow, and a couple of others that I can’t remember. They all end up having the same issues.

The printing settings I use are usually the Bambu PLA Basic preset. I have swapped all of the extruders out to the BigTreeTech Panda extruders.

Someone commented on another site that “you don’t ‘lose’ hotends because it’s clogged” but I don’t know what else to call it. The printer will give me a “failed to remove from extruder” error and when I clear it, there will still be filament in the hot end. I’ll heat it up to 250 degree Celsius and use the NoClogger tool to push the filament through. Sometimes it works, but most of the time it does not. I’ll then remove the nozzle and use the NoClogger from that end and again, sometimes it will clear the filament but most of the time it does not. It doesn’t matter how much pressure I apply (I’ve bent multiple NoClogers trying), it will not budge. Another person commented that “I only use the needles to poke from outside the nozzle, run cleaning filament, cold pull. I only swapped out original nozzle to test the Obsidian HF”. In the beginning, the needles worked but they were not sturdy enough and bent so that’s when I switched over to the NoClogger with a T-handle so I could get a little more leverage.

Here’s an example of the steps I go through when I get the error:

Stop the print, unload the filament (which doesn’t always unload, sometimes I have to break/cut it above the extruder), pull the hot end, put the temp up to 250c, run the NoClogger from the top and attempt to push the filament through the nozzle and if that doesn’t work I’ll remove the nozzle and attempt to push the filament back up through the top. If it clears, great! If not, replace the hot end. I will then pull the extruder, unscrew the tension screw, run the NoClogger through and if there are no obstructions, retighten the tension screw and replace the extruder. If there’s an obstruction, completely dis-assemble the extruder, clear the obstruction, reassemble the extruder, put it back on and then install the hot end.

I’m at a loss for why the filament will not come out of the hot end when I’ve heated it up to 250 and how it’s just completely jammed in there and will not budge no matter how much pressure I apply. Any and all help would be extremely appreciated!

I have lost a few hotends myself. Never to a clog though. Always bending following either a poop chute clog or warping/curling.

Regarding nozzle clogs, I did learn quickly that with the stock hot ends, I should only ever do the hot hex wrench cold pull. Nozzle/Hotend Unclogging Procedure for X1/P1 | Bambu Lab Wiki

And do that several times just in case, even refilling the nozzle to pull the gunk out. Although I do use the heat cartridge to get to temp when inserting the wrench. Not advisable though: Risk or burns and hot end damage!

At least in my case, push type approaches (needle) always left the gunk in the filament path.

In one particularly “memorable” case, a nozzle clog led to extruder contamination (filament grinding). So there was a combination of reduced extruder force on the filament with a dissimilar material reservoir in the filament path…

Hope this helps, ![]() &

& ![]() ,

,

Eno

Thank you @EnoTheThracian!! I will definitely try that the next time it happens!

Sounds to me like your filament cutter isn’t cutting. If you manually activate it you should be able to easily pull the filament back by hand. Suggest inspecting the blade. There is spares that ship with the printer. Also make sure that the head can reach the front left corner as this is where there is the little arm that activates the cutter.

Thanks @JonRaymond. The cutter does stick on occasion but it usually works just fine.

What size nozzle and what brand nozzle?

What other mods have you done to printer? Have you edited the start or end G-Code?

Do you have an anything plugged into USB-A socket behind touchpad?

What is the NoClogger? Name is self-explanatory but where is the model located to make one or is it a tool you purchased? Whole purpose of using the 1.5mm hex is it is metal so won’t melt.

I like using hex key that has the hex ball type tip on the end as that indent allows melted filament to cling to hex better when you pull it out of hotend.

I’m jealous, I haven’t killed 10 nozzles since the ender 3 days!

If you have 10 samples of “clogged”, you should definitely autopsy them to see wtf is going on. Are these aliexpress ones or something? You might find the same debris in each of them, which would be concerning that something non-PTFE on your filament path is wearing/abrading down.

Use a soldering iron, a vise, and a needle. Heat it up, poke at it and wipe it our on a piece of white paper. Look at the shmoo for metal particles, etc.

What is the temperature where your printer is located? Are you printing with the top glass open/removed and the front glass open? It could be heat creep especially since you are printing with PLA.

Have you replaced the PTFE tubing recently? I was shocked how much wear I had on mine after printing only PLA and PETG.

The cold pull as mentioned by others does a better job of clearing the filament path. Sometimes it can take multiple pulls.

Mainly 0.4 but it has happened with 0.2 as well. I’ve used Bambu (from Bambu), RugooSpink, Enomaker, HzdaDeve,(from Amazon), and some off of Aliexpress that are listed as follows: “Hotend For Bambu Lab p1p X1C P1S X1 V2.0 Upgrade Hot end Kit Print Head Bimetal Nozzle 3D printing parts for bambulab”.

The NoClogger (https://noclogger.com/) is metal and I purchased it from their website. Thanks @Wsquared58!

Have you been replacing the cutter blades?

Some of the hot ends were from AliExpress…others were from Amazon and Bambu. I will attempt to autopsy them next time. ![]() Thanks @Bullocks!

Thanks @Bullocks!

Yes, I’ve replaced them multiple times over the last year. Thanks @krellboy!

I keep the area between 66 & 70F. I have a vented top glass holder. I have printed with both the door open and closed. I’ve replaced the PTFE tubing a couple of times in the last year. I was shocked as well. Thanks @blchandl2!

I think you will have intermittent problems with the .2 nozzle separate from the others just based on the size.

Why the large assortment of aftermarket nozzles? As far as I know there is only a single approved Bambu Lab partner, E3D. They make a nozzle that BambuLab has approved.

All the rest are just making money riding Bambu’s coat tails and are not approved manufacturers

@Wsquared58 mainly because of price. I was able to get hotends on AliExpress for less than $10 and I was going through them like a hot knife through butter. ![]() Not to mention the ones I get direct from Bambu the nozzle does not come off.

Not to mention the ones I get direct from Bambu the nozzle does not come off.

Before I bought my P1S I had an Ender 3 Pro and was constantly buying this part or that part, bed probes, different nozzles and extruders in a never-ending quest to find the right mix or combination of parts to effectively print models.

Of course you had to buy nozzles to replace the damaged ones but in general most problems can be resolved without spending a penny on aftermarket mods of questionable quality or function.

Like people spend coin on a Panda Touch to emulate an X1 machine. A better option is to get a cheap tablet and install Bambu Handy on it and mount that to printer. Using Handy you completely avoid the firmware issue associated with the Touch.

Can you rule out contaminated filament? I had a batch of eSun filament were all rolls of a pack of 4 were contaminated and constantly clogged the nozzles. I dumped them and I could save the nozzles with cold pulls . But I had to take the extruder to pieces and clean it very well. I bought some BBL not hardened nozzles from the internet which were new. I like them more than the harded, I have the feeling there are less problems with them. I do not print CF material.

If I had to guess, the very remedies you thought would fix this - like swapping in third-party nozzles - are likely a contributing factor cause. Obviously this should not be happening. If all four printers are modified, and all four are failing, that in and of itself is a common cause. Nobody else is reporting this level of failure, so it’s time to focus on the common factors.

Rule #1 of Troubleshooting: Change only one variable at a time!!!

Rule #1 of Troubleshooting: Change only one variable at a time!!!

Shotgun troubleshooting wastes effort and muddies the data. Work systematically and let the results reveal the cause.

Key question:

Do you have at least one stock printer (no mods)? If so, does it show the same issues?

You titled your post “Loss of Multiple 0.4 Hot Ends.” How do you define “loss”? Are you discarding them after failed clearing attempts?

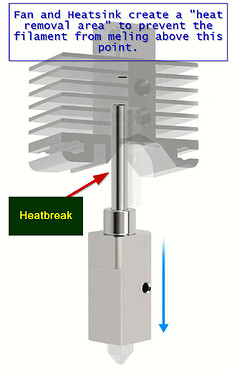

Likely Cause: Heat Creep – A well understood problem and easy to remedy.

Your issue matches classic heat creep. PLA softens sooner than PETG, which may explain why it’s the only material causing failures. If the heatsink isn’t shedding heat effectively and/or your chamber air is hot (50°C+), this creates ideal conditions for jams.

This diagram shows the heat break’s role. If cooling is inadequate, heat migrates upward, softening material prematurely and locking it in place. Unless I misunderstood your post, this sounds like what is happening in your situation.

Things to Try:

- Return one hot end to stock condition to establish a control. Use this as your baseline.

Change only one variable at a time. - Run printers with doors open and cover off to lower ambient temp.

- Measure chamber temperature during prints and log it. Use a simple $9-$12 logging thermometer:

https://www.amazon.com/s?k=logging+thermometer

Track time and temp when failures occur to spot patterns. - Measure heatsink temps directly:

- Tape a thermocouple to the heatsink and log temps during prints. You’ll need to get creative in routing the wire and positioning it securely inside the fins of the heat sink and routing the cable along the PTFE tube so it can travel. Use Kapton tape, which is designed for high-temp applications and works well for this task.

- Digital Thermocouples ($9-$14 each): https://www.amazon.com/s?k=Thermometer+with+Probe%2C+TM902C+Electronic+Digital&i=industrial

- Kapton Tape: https://www.amazon.com/s?k=kapton+tape&i=industrial

Tutorials:

While this may seem like a lot of effort, consider the amount of effort you’ve already performed and it appears you are no closer to identifying the problem. There’s a saying in systems diagnostics: “You can’t control what you can’t see and you can’s see what you don’t measure.”

Your next step is to simplify variables: return one printer to stock, gather chamber and heatsink temp data, and work from there. Without a control and logged data, you’re just chasing symptoms.

@Don_Manfredo I have had the same issues with multiple different brands of filament.

@Olias Thanks! I will return one of them to stock and start keeping a log of what happens. Appreciate the suggestion!