From one end of the body to the other there is .010" difference in ID width.

The slide is loose at one end, tight at the other when opening and closing.

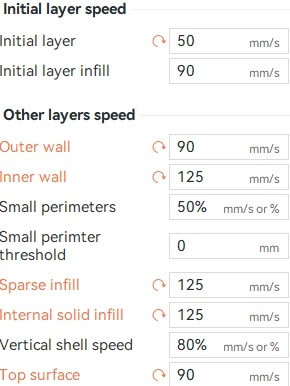

0.4 nozzle, 0.2 layer, dry PLA+, almost 500hrs. on printer

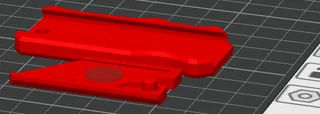

Printables: Talon Utility Knife V2

Thanks

What makes you think this is not the model itself?

If it is from printables, the designer didn’t create a profile that would guarantee a quality print.

Thanks for your reply

The design came from, “Hall Precision Manufacturing”, in house CNC Milling, CNC Turning, CAD Design and 3D Printing capabilities. They sell them in Titanium for $35, CAD file $3 or free on Printables.

I’ve printed over 100 of them, but recently I’m having this problem.

Can there be a setting change or the filament not being calibrated cause this.

I’m not sure if this happen after I went to 2.0 slicer.

My speed setting shouldn’t be to fast. I’m using SUNLU PLA+ 2.0 Black and eSUN PLA+ Red for the 2 tone colors.

You might need to tram the bed.

Thanks

I didn’t know the Mini could be trammed.

I checked Bambu Wiki, now if I can get up the nerve to do it.