I get your point, but $130 for 750g of filament says otherwise. ![]() No room for tourists on this trip. I’ll stick with whatever is working.

No room for tourists on this trip. I’ll stick with whatever is working.

Speaking of Magigoo…

They may have a specialized glue for nearly every filament under the sun, but nothing beats good ol’ trial and error.

I tried Magigoo PA on my carbon fiber plate with PAHT-CF once — it stuck so well I nearly ripped the soul out of my supposedly “indestructible” build plate. ![]()

If the special glue grips like a vengeful ex, Magigoo Original is a rock-solid all-rounder that’s absolutely worth trying — works like a charm without trying to take your plate hostage.

I’ve been experimenting with my PPA-CF spool — not quite as outrageously priced as PPS-CF, but still expensive enough that you only want to mess around with one spool… you know, for “science.” ![]()

I concur with @maximit : Bambu’s PPS-CF bonds just find to Bambu’s textured while printing and seems to release just fine when it cools off. I don’t see a need for any kind of glue or bond breaker for that particular configuration. I think Bambu should revise it’s printing advice.

I used to think the same — until I printed something that covered most of the build plate. Suddenly, warping showed up like an uninvited guest at a dinner party. ![]()

Just a heads-up: larger models generate more internal stress, and even if smaller parts stick like a dream, big prints can still lift at the edges. Model shape matters too — corners love to betray you.

These days, I just slap on some glue for nearly everything. Time and filament are too precious to lose over “trust issues” with bed adhesion. Losing a big print just because I skipped glue? That’s filament down the drain and my evening ruined. ![]()

Let’s be honest — there are two kinds of people in 3D printing: Team Glue and Team Denial . I proudly stand with the glue crew. I’d rather spend 10 seconds applying glue than spend 35 hours printing… just to end up rage-quitting at layer 923.

Well, it’s always hubris before the fall, isn’t it? I got a perfect print:

but then I couldn’t get the base of the support trees off the build plate. They are welded on. So, I’m going to do the experiment I didn’t want to do, and reduce nozzle temp to 320C on the first layer and use standard magioo on the build plate to see if the tree stumps will come off then. Argh.

It really depends on material. PLA, PETG I use a polyura plate (frostbite, supertack) instead of glue. For ABS and ASA I have not needed to use glue either in a while after adding chamber heater to X1 and P1s. I mainly use nano polymer adhesive for large full plate nylon prints.

If I had somehow made the tree supports solid instead of hollow, I bet I could have maybe pulled them off. I’ll have to look to see whether or not there’s a setting which allows that. Either that or find a less agrgessive way for the tree stump to grab the plate.

This has come up in other contexts also, so now I have a reason to look into it more thoroughly.

It worked! Tree stumps easily removed. OK, then, that’s my new normal. ![]() Regular magigoo will be my goto for printing this filament.

Regular magigoo will be my goto for printing this filament.

By the way, I noticed this morning when I was hunting around for magigoo HT that there’s this new insanely expensive magigoo kit for applying magigoo in what I assume is a more uniform way than usual:

because, evidently, the thickness at which you apply it is part of the “secret”.

Perhaps just a regular silicone squeeze would be good enough?

I’m proudly team glue but I still try my best to solve structural issues causing excessive warp

Cheap bambu liquid glue with some tissue and hot water to spread thin works great as well. You only start to see marks after a couple prints. Easy to fix by wiping it with warm water and tissues again.

I have a strong hunch that when we can get good garolite build plates for the H2D then that will be a good match for this filament. For instance, PETG sticks well to it when hot and slides off, usually without much if any effort, when it cools to ambient. I think those may be coming online soon.

I still think if you guys try nano polymer you will not use any other adhesives again. It does not leave a residue, releases when cool and you only need a few drops every 10-20 prints. Its not cheap but lasts a long time, Im still on my first large bottle after 8000+ hours. It also works for all filaments, dont have to get a specific one for different filaments like magigoo.

How are you spreading it? With that little nylon brush that they provide with it? Maybe I’ve been using way too much of it (I do the circle with the x through it, like visioneer recommends), but it’s way more than just a few drops. The problem I’ve had with it is that it sticks far too well. Effectively weldsthe print to your build plate.

Yes i made the mistake of using too much the first time I used it and it ripped my smooth PEI plate. I only apply a few drops (literally like one in each corner and a couple in the middle) and spread it with the included paint brush. Smooth plate works the best as it spreads more easily on it. I wish H2D had the engineering plate as that was my favorite one to use it on, that and Energetic brand PEA.

If there were some other solvent it could be diluted into (without destroying it), that might be a good way to both water it down and spread it around.

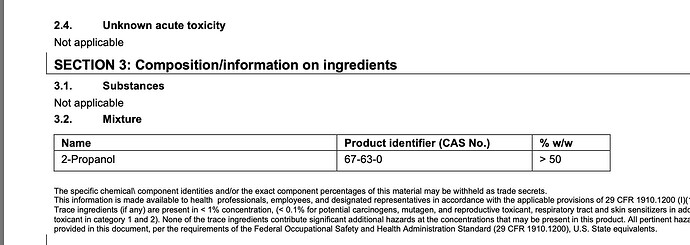

Send them an email, they are good about replying promptly. Propanol alcohol should work as that is what they use, from the MSDS:

Perfect! surely that would work if it’s already more than 50% that.

Let us know how it works out.