Just got my A1 printer and need help troubleshooting a potentially basic problem.

I designed something in Onshape and wanted to print the first part which is basically a rectangle shaped frame with some holes in the base. I exported from Onshape as an .STL and sent it to BL, where i didn’t change any of the default settings except for checking the enable supports button, since it told me it needed support for the small arms that poke out of the edge.

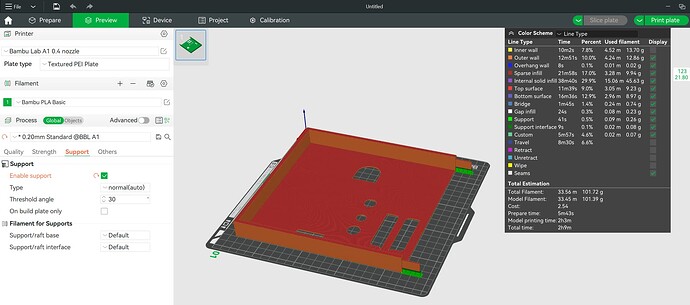

I hit slice plate and didn’t notice any flags so I sent it to print and the print “completed” but its only small part of the design. I attached a picture of what I got which is basically just the base and what looks like the start of the support. The rest of the part didn’t print but the software thinks it is complete.

I also included a screenshot of the slice plate screen. It seems like I’m not able to attach the .STL file, but I’ll include a link to the Onshape document.

1 Like

Try increasing the heating bed temperature by 5°C or even 10°C and either clean the heating bed properly or, better still, help it along a little with a glue stick.

To do this, heat the heating bed to around 40°C using the control unit and apply a very thin layer of glue stick to the panel. Then rub again with a damp kitchen towel. It should really only be a tiny amount.

Overall, the print seems to be holding, you only have regional problems with the adhesion of the glue.

So as I said, increase the temperature on the heating bed and clean it - or/and help with glue stick or spray adhesive in minimal quantities(!).

2 Likes

I don’t think it is mainly a bed issue. Only the first layer printed. Looks like after the first layer, the nozzle clogged or the extruder gears chewed up the filament. The printer thought it was still extruding but nothing was coming out.

-If you manually heat the nozzle and run the extruder, does filament flow nicely?

-is the roll of filament wound nicely and not tangled. Is is free to rotate?

-can’t hurt to improve bed adhesion with some glue stick just to make sure the first layer isn’t lifting/rippling and blocking the nozzle for subsequent layers.

2 Likes

Actually, I did get an error mid-print saying the cutter was stuck. It turned out that the filament had somehow gotten off the spool and became tangled so I had to manual untangle it while the print was paused. After I hit go again it seemed to be working, but I’m sure you’re right that the printer “thought” it was printing but nothing was coming out, probably as a result of filament getting snagged during that error.

Thank you! I will try manually running the extruder to see if that was the issue.

1 Like

UPDATE: turns out there was filament stuck in the toolhead that I was able to remove by following a tutorial on Youtube. I put everything back together and started the print again, but this time after getting about 30% through the print I got an error saying the filament had run out (it hadn’t, the spool is nearly new). I went through the process of loading new filament (even though it was the same spool) and after it was loaded the print continued.

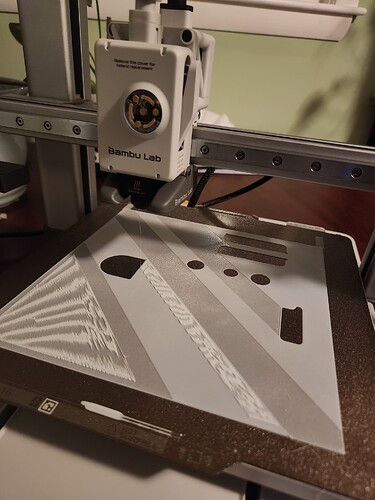

Alost immediately I stopped the print because something was up. Instead of printing clean and flat like the first layer I was seeing this weird texture. I attached a picture where you can see. Also you’ll notice some melted filament hanging from the nozzle after the print stopped. Is this normal and i stopped the print prematurely? or is something else wrong? I don’t know what triggered the printer to say the filament spool had run out.

Can you rename the file to .3mf and upload it here?

1 Like

You have two lines at the front of the printer which the A1 uses to test the filament is coming out properly.

You normally only get one.

You have two.

Two questions:

-

Did you remove this line/lines from the earlier print and these two lines are from this print?

-

Did you forget to remove the line the first time, so only one line this time and one from the previous print, with two lines total?

Both point to different issues.

-

The printer thinks there is an issue right from the start. This may or may not be important though.

-

The second line is printed in a different place to the first, this could mean the Y offset from the first to the second prints are very different. It could instead mean the nozzle is bent.

Part Studio 1 - Frame M.3mf (52.7 KB)

Yes sure. Do the file types mean anything different to BL? I just saw a tutorial explaining to sport as STL which is the only reason I chose that to send to print.

Both lines must be from my second print attempt because in between attempts I also cleaned the plate.

Also I don’t think this matters but between attempts I also changed the hole where i loaded the filament. I don’t have AMS add-on but the print head has four slots for four colors and when i cleaned the stuck filament the first time and loaded new filament I just happened to put it in a different hole. Don’t think that matters but figured I’d mention it.

Thanks!

The forum won’t let you upload an .stl so sometimes people rename them to .3mf to get around that. Then when people download them they rename them back to .stl. It’s perfectly fine to print in .stl format. I’m printing the .3mf now but the model looks great in the slicer.

Can you take the build plate to the sink and scrub it with dish soap? Try not to touch the build area during the process.

1 Like