I am new to 3d printing, so I might be missing something obvious, but suddenly a day or two ago I have been having some printer issues.

Have a P1S (with stock hot end) for about a month now (and about 100 hours of prints), lots of good prints. Using Bambulabs filament (Mostly pla, a few PETG and one ABS print. Most is PLA Basic, one or two PLA Matte). About two days ago I had started to have mostly constant failed prints.

It started when I had a failed print with some weak stringy layers in the middle of the print (First time using PLA Basic Grey) - but I was not worried yet as the printer is installed next to the front door and I had a large delivery during the print so there might have been some shaking of the device.

Next few prints also failed using other colours I had used successfully in the past.

Tried cleaning the hot end (Poking the needle into the end to remove a clog if that is what it was). Would print the sample tests well (The calibration squares, calibration lines, and some 10mm cubes I tested in a few colours as well).

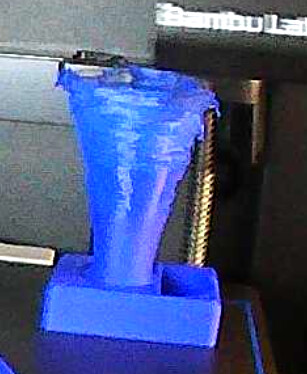

Then when I try to do longer prints they fail after the first 100 or so layers. Here is an example of what the top half looks like (I forgot to take a picture before I separated them apart). This was supposed to be the top of a funnel.

Some prints look like this (Which looks like under-extrusion?)

But even though it looks like under extrusion, I did run the flow rate calibration right before printing.

Ive tried cleaning the nozzle a few times. I have also partially removed the hot end to try a cold pull described here: Nozzle/Hotend Unclogging Procedure for X1/P1 | Bambu Lab Wiki

The common problem that seems to happen during cleaning is that when I manually extrude the filament it seems to curve back up towards the nozzle rather then coming straight down. I do eventually get it going straight down, but that seems to only last for a short time before going back to the irregular.

I have not tried replacing the hot end with the spare hot end that Bambu comes with.

Should I reach out to support? Or is there something that I can do to resolve the issue?

Edit, I did try another print and stopped it as the stringing started to happen - here is the shot from the top:

Edit2: I do have a time-lapse of one of the fails, but it is a large file so cant upload it here. Can find a way if it would be helpful! Here is a screen cap of it