Hey guys almost every time the nozzle hits the tree support and make the support fail which in turn I have to stop the print or cancel it can anyone help

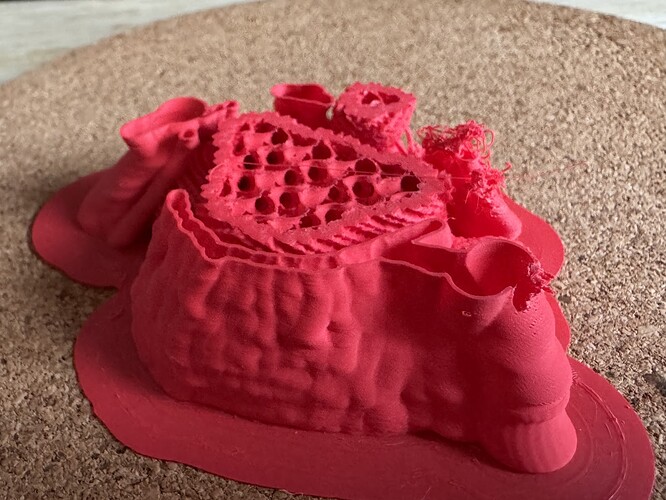

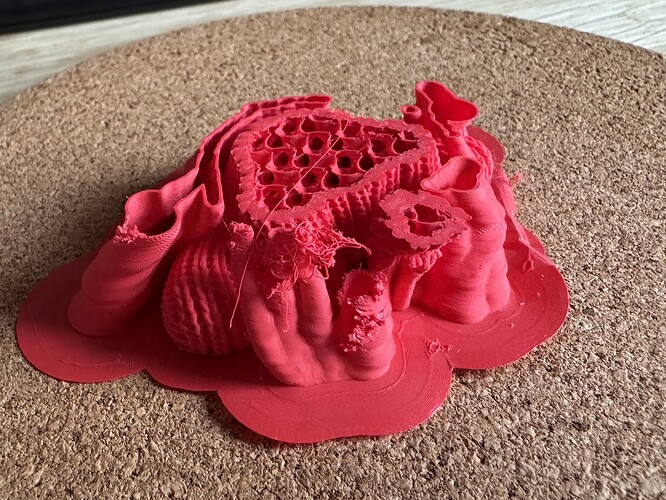

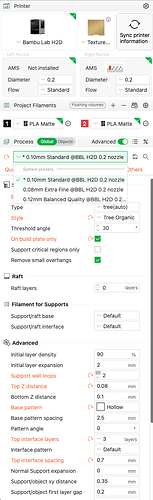

This has also been happening to me with different 0.2mm hotend supported models off of makerworld using PLA basic and matte. I am using default tree support settings. I changed to Style of Tree supports from default to tre strong and now I have other issues such as gaps in the support and purge tower which causes stringing. I am using just opened Bambu Labs PLA Matte filament fresh out of the vac bag.

Just a heads up. Sometimes filament is wet, straight from the package. Not saying this is the issue. Just wanted to let you know.

More often than not.

Also, gyroid can cause issues with certain models due to its structure.

Perhaps try a different infill, such as cubic, adaptive cubic, or something similar?

Hello there, I am new-ish at this and am curious as to why both the skirt and tree supports are used here? Is it for extra support? Is it recommended for certain prints? I’d love to know if you have time ![]() thank you!

thank you! ![]()

Ooo I assumed they were dry from the warehouse! Thank you for this info!

I just dried it the AMS 2 Pro for 8 hours last night (after the failed supports) and weird missing sections of the tower just to make sure that moisture is not the issue and will try printing it again. I had not opened it for 3+ weeks after receiving it so I thought that the desiccant pack inside of it may have ensured it didn’t absorb any moisture after it shipped from the warehouse assuming it wasn’t very moist right before shipping. I’ll make sure to dry every filament before I use them. I also started a print since I last commented, and it is using 0.10mm layer height and i read that setting support wall loops from 0 to 2 can help make them stronger and prevent them from breaking. supports look fine now and have grown beyond the layer height where I had them break on previous prints. The difference is that the previous prints had that setting at 0 and the layer height was 0.08mm .

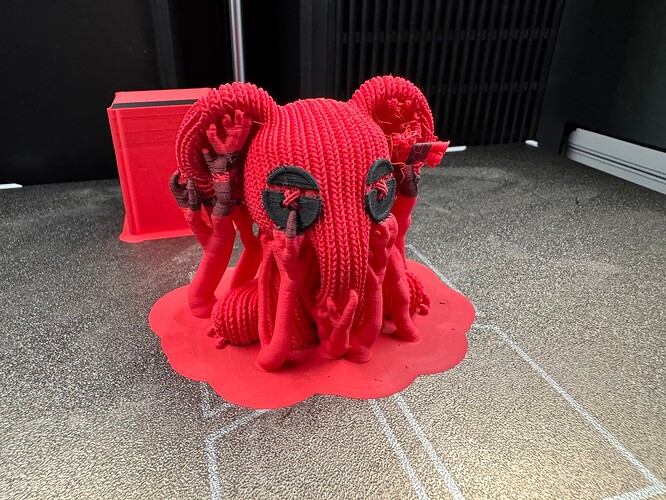

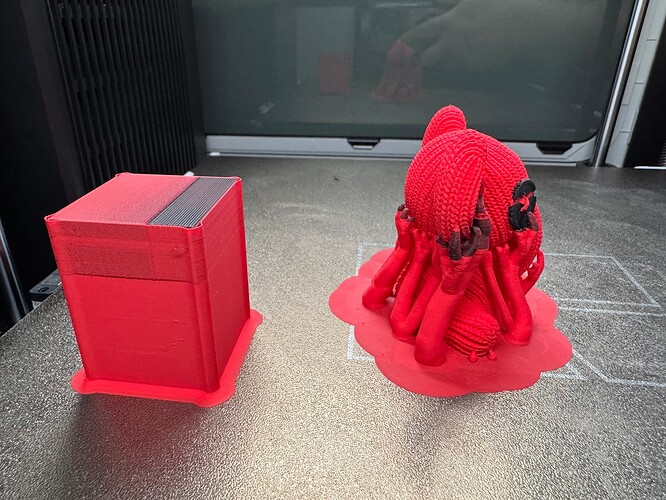

Here is a battery pack I am printing using a 0.2mm hotend (settings on makerworld are for 0.4mm hotend with a layer height of 0.2mm and i am printing it with most of the default Bambu Studio settings for the 0.2mm hotend)

There’s a setting under the others tab near the bottom called “reduce infill retraction”. Disable this. What it does when it’s enabled is turns off Z hop and retraction during travel moves. It’s supposed to only do it when traveling over infill areas, but if it travels over the infill and also over a tree support it can make contact and knock it over.

thank you soooo much! this worked!!! my supports stopped getting broken…

but then i had a different issue (black filament seemed to have gotten moist after a few days of intense fog and rain which effected the button eyes of the model i was trying to print) . I dried the black and red again in the AMS 2 Pro and will try to print this model again using 0.08mm Extra Fine layers this time around and hopefully the black filament won’t have “pressure” error issues due to being wet.

one more thing, i will disable “Others/ Flush Options / Flush into objects support” since some of the black filament is sticking to the red part of the model where the hotend flushes into the object’s support.

I also switched from gyroid infill to triangle infill just to eliminate one more thing that may have effected the quality of the 3D print based on L0rdS474n comment

Didn’t know that it would also do that… do you have a sample?

I’m not quite sure what you’re asking

The “reduce infill retraction” feature turning off z hop over other features as well…

Ohhh. I don’t exactly have any video evidence, but I can share an experience.

I was printing one of my 2” mini hitch models and even with gyroid and rectilinear I was getting infill scraping while the print head was traveling. I watched it really closely on the Z axis to see if it was doing the Z hop, it was not. Disabled reduce infill retraction and all was well again. Many others have the same experience too. It’s just a bad setting that needs to be deleted. The time savings is a few seconds overall and isn’t worth the risks.

I print large helmets and notice sometimes the left half experience layer shifting but not the right side.

Does this have something to do with that

I don’t think so. It’s possible yours is due to warping on one side.

Glacier plate. Totally glued onto the bed long after it’s cooled but good theory

Are we sure the plate itself didn’t warp up from the bed too? I’ve had that happen plenty of times. It doesn’t take much to cause a defect. Sometimes it may not even be visibly warped.

I have fought 3-4 rolls of filament with an 80% or higher fail rate trying to tune this printer to stop doing this. It had gotten to the point I was wanting to return it. I have searched for this answer I knew it had to be a certain setting I was missing and this is the one.