I’m using a couple month old P1S. I’ve done lots of prints but this is the first time I’ve run a print on this printer that filled the bed (this print is 240x240). I’m using Elegoo Rapid PETG which I’ve tuned my own profiles for that give generally good prints in most cases. My top surface speed is 40 and my top surface flow is 1.02 against my filament profile flow of 0.98. I’m not using Variable Layer Height. I have determined a Z Offset of -0.06 which has worked great for all my prints up to this point. I’m applying this by modifying the Machine Start G-Code in the printer settings. The “G29.1 Z-0.06” command is placed right after the standard Bambu Z Offset adjustment when running a Textured PEI Plate so it’s applied at the correct time and doesn’t get negated by other commands. I’m using a Biqu CryoGrip Pro Glacier build plate. I ran Bed Level before the print.

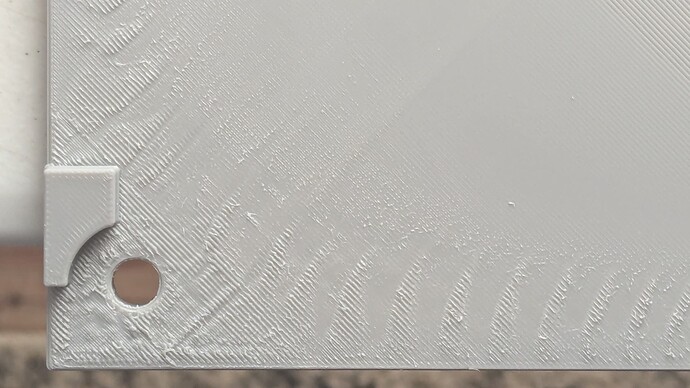

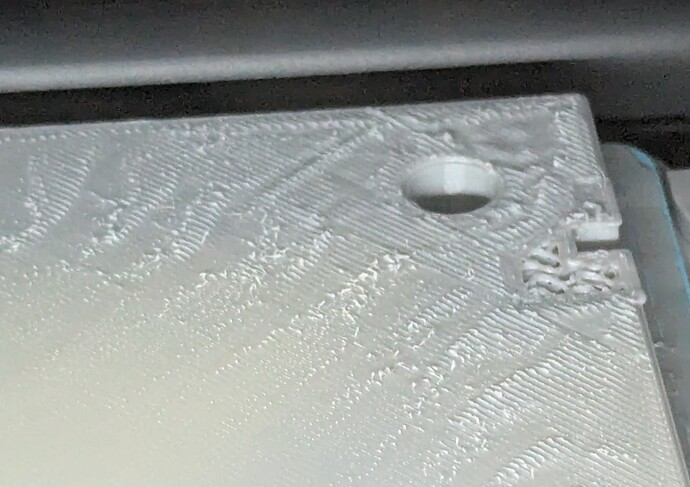

Here are some images of what the print looks like. Note that the top view shows the plate flipped front to back (the problems areas are really towards the back right of the plate). There are a few different issues. First are the artifacts showing mostly at the back right. These extend forward along the right edge and back along the back edge. They also show up along the left edge and extend forward along that edge. These artifacts stay towards the edges and become less harsh as you move forward on the plate. The forward edge is almost perfect. There is also some gaping in the extrusion lines towards the center of the plate.

It seems like the issue worsens the farther from home/probe origin the nozzle prints — back/right is the worst, front/center the best (although the center suffers from extrusion gaping). Could this be mesh resolution limits or Glacier plate edge deviation? I preheat to PETG temps before probing, but I’m wondering if a longer thermal soak, double ABL pass, or height-range modifier to slow top layers could help PETG close more evenly. Anyone else seeing this on large-bed PETG prints?

Any ideas on what’s causing these issues? What would be the recommendations to minimize the problems? Appreciate any guidance.