My P1S+AMS is having an unusual issue that I can’t find any solid answer for. It seems like some sensor is getting constantly triggered causing what you can see happening in the video below. It might be a bit loud if you have headphones. Tried to zoom in and out to give a better view of what’s happening when it’s piping filament, if you’d rather have a video of something else for longer/shorter just let me know:

For lack of the correct technical term, my Printhead is stopping mid print, lower the Z, and moving the X+Y to the front+right corner “randomly” (for now I’ll just call it “cornering” due to my ignorance of the issue).

What happened before there was a problem:

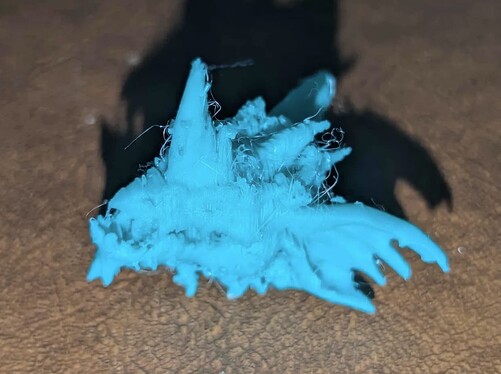

- I originally printed this monster head that turned out pretty nice, along with other minis:

- Decided I wanted to try Sunlu’s Meta (Mint Green) as it was touted as being great for Mini printing and wanted my prints to be a bit nicer and maybe a bit stronger.

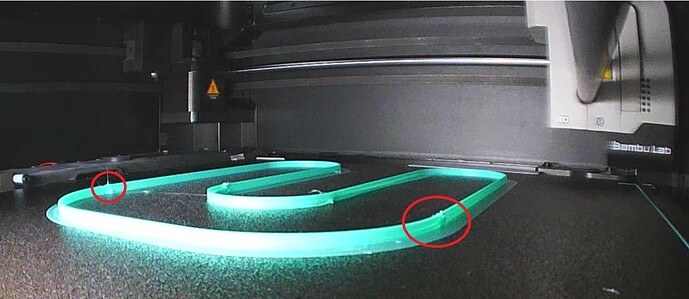

- Ran a Temp test as I knew it printed at a lower temperature (I know it looks blue but this is the Mint Green just an odd trick of the camera):

Note: Temp Test require altering the GCode but I reverted that.- THOUGHT I updated the print temp to be around 200-205 on a new copy of the Generic PLA profile.

- Tried printing the second head of the monster mini and it looked like this:

- Updated the temps and it was better but still bad (post removing supports etc):

- Decided to try a flow test as I realized the flow on the Generic might be too slow for the Sunlu Meta, but it was giving issues as well.

- Now it happens for ALL prints and ALL filaments I’ve tested.

My observations:

- Seems to happen consistently-inconsistently

- For instance, in the flow test I mentioned, you can see some blemishes where it started lifting up, but in consistent spots (circled 2 of the 4-6 spots that it would “corner” at), but then as the print would continue, those spots would no longer cause “cornering” and then later on it would again.

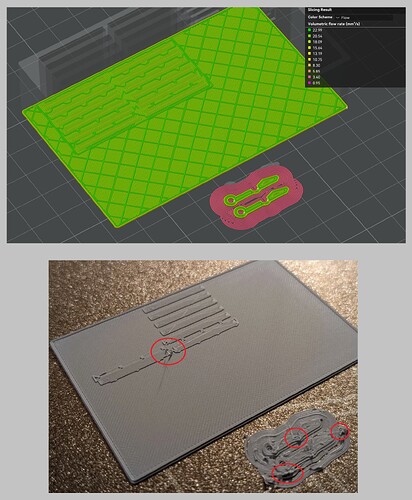

- In this image you can see it tried to print the inside of an SD card holder and a couple of hinges. It had few/no issues printing the large base, but lots of trouble printing the hinges, and then when it went to start printing the slots on the base of the box, it started cornering again.

Things done to fix it are as follows:

- Updated the temp and flow for Sunlu Meta, no luck

- Downgraded the firmware from the latest.

- Bought a brand new SD card in case the prior one was corrupted as suggested by others

- Tried multiple STL files of various types (mini figures, flow tests, etc)

- Tried multiple filaments (Bambu PLA, Bambu Matte, Bambu PLA, SUNLU Meta) in multiple AMS slots.

- Checked printhead and rods for any obvious issues

- Cleaned the printbed

- Turned it on and off again

- Reran calibration from the Bambu Program on PC

I’m not sure if the settings I used with Sunlu meta screwed something up, or if it was complete coincidence. I also know there are a 1000 things I could try on top of the things I have. But I’ve been down the “spend lots of money and time and try literally everything” road on another machine, only to still have no machine, less money, and a hate for 3D printers.

I’d love if someone who has a great knowledge of these machines could help me pinpoint the issue and steps to fix it. Please let me know what else I can provide to make things clearer or things I can test. Also, if I said I did something, but you suspect I need to recheck it, I’m glad to do that as well. I assume anything I said can be contested.