Hi all,

I’ve been printing with the A1 mini and later the A1 (upgraded after a year) for almost two years, both using AMS Lite. Overall, the A1 series has a fantastic price/performance ratio, and I’ve had a lot of fun with it – most of the time.

Unfortunately, the bed-moving design caused a few disasters:

The hotend started printing into itself on multiple occasions. Yes, the detection feature was enabled. No, it didn’t help. Repairing the toolhead was a pain in the ass and definitely not part of the fun.

Here’s when it happened the first time:

AMS Lite – The Struggle

Aside from three major clogs in ~1.5 years, the AMS Lite struggled with specific filament types: PLA Matte, PLA Silk, PLA Silk Multicolor

I had to switch to external inserts for those. I saw on multiple occations both in forum posts and on the Bambu website that the “big” AMS is apparently better at handling filaments.

So, during the anniversary sale, I bought a P1S with AMS as a second printer.

After 2 weeks of testing, here’s my honest comparison:

Advantages of A1:

- Easy and fast hotend swap

- Automatic flow calibration (why not possible on the PS1???)

- Slightly larger build volume

- Open frame = easier repairs

- Automatic hotend tip cleaning is acceptable

- Touchscreen is very convenient

- AMS Lite with mods = faster filament swapping compared to AMS

- Slightly quieter than P1S

Advantages of P1S:

- Z-axis bed movement means less shaking, better adhesion, and hopefully less repairs

- Display, although shitty, stays on permanently (A1 turns off after 15 min)

- Better plate holder – alignment issues are rare

- Can print more materials like ASA (still waiting for the Bambu ASA to arrive)

My Take after 10 days with the P1S.

The A1 is even better than I thought. But if I had to pick only one printer, I’d still go with the P1S – mainly to avoid those clogging nightmares I had with the A1.

What Drives Me Nuts About the P1S:

1. Nozzle Cleaning is Terrible: About 1 in 10 prints fail due to filament sticking to the nozzle tip. The A1 was way better here.

Hopefully fix incoming:

2. AMS (Not the Lite) = Frustration Overload

Inserting filament = guaranteed sore fingers

Spools under 20% jump like crazy

… had to use this mod to prevent it

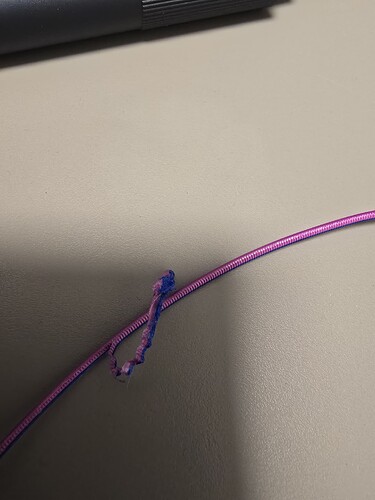

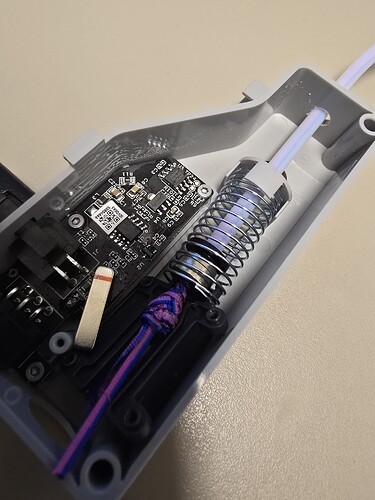

And the worst: ![]()

PLA Silk Multicolor (Bambu brand, dried 24h) total jam. Took apart the filament buffer, found a full filament knot. Wasted over an hour fixing it!

NEVER use Bambu PLA Silk Multicolor in AMS. You’ve been warned!

3. Display = Useless in Case of Errors

When something fails, the P1S just stops and you see the pause symbol. No error message.

You have to open the app to see what’s wrong. Why?!

![]() Final Verdict:

Final Verdict:

I expected more from the P1S out of the box.

It works, but you’ll need a bunch of mods to make it act like a printer should.

AMS is… honestly awful, even compared to the borderline dysfunctional AMS Lite.

Attached are some pics of today’s repair therapy session.

Let me know if anyone had better luck with PLA Silk inside the AMS, or has a working workaround.