Hi everyone,

This is my first post here, so hi to all! I’m new to 3D printing and definitely feeling the steep learning curve. I’m hoping for some advice from more experienced users regarding PET-CF printing on my H2D.

Context and Calibration

My printer is fully calibrated, including motion accuracy with vision encoder alignment. When using PLA (0.4 mm nozzle, default profile), I got an almost perfect 3D Benchy as expected: smooth surfaces, aligned layers, and sharp details.

I switched to Bambu PET-CF for a new project that needs high temperature and heavy-duty properties and I am not experiencing the same results.

Filament and Print Setup

- Filament: Bambu PET-CF

- Dried in AMS-HT at 80°C for 12 hours (humidity stable at 10%)

- Plate: PEI textured

- Nozzle: 0.6 mm (left extruder)

- Printer: H2D

- Chamber temp: 50°C (default)

- Fans: min 10%, max 30%, aux off (default)

Profiles tested

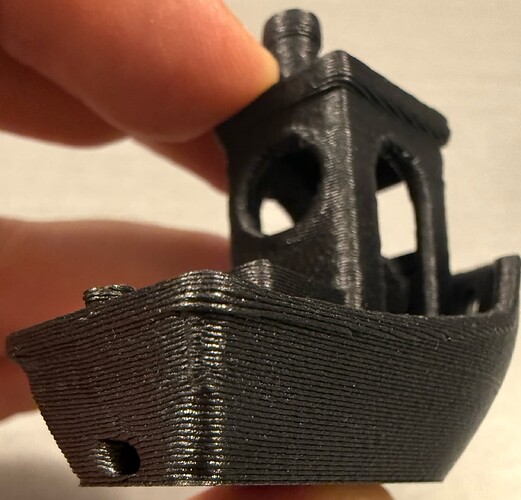

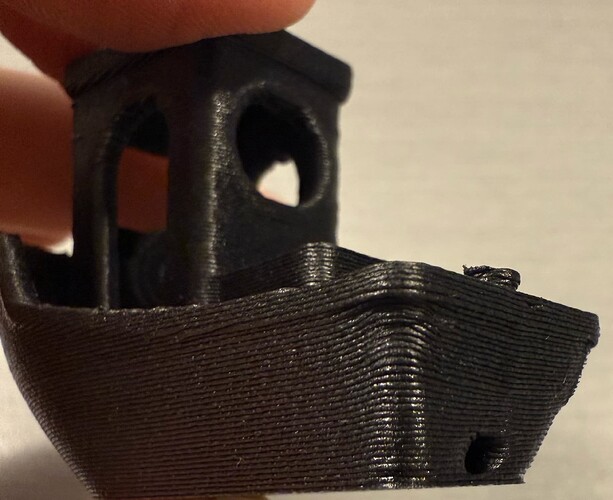

- 0.24 mm (default): terrible hull results: rough surface, misaligned lines, front hull apex denting inward, and back corners of the Benchy is curling up.

- 0.30 mm (default): hull lines greatly improved but still getting the same front dent at the apex of the hull and back side of the Benchy corner warping.

What I’ve Tried So Far

- Increased nozzle temp from 270°C to 280°C with no visible improvement.

- Verified extrusion multiplier via a 20 mm cube test (double 0.6 mm walls). All sides within 0.01 mm tolerance, extrusion multiplier at 99.6%. Flow seems fine.

- Cube shows elephant foot, so I reduced bed from 100°C to 90°C - foot persists, and 3D Benchy issues remain.

- Reduced outer wall speed to 40 mm/s (max volumetric flow at 8 mm³/s, 0.30 mm height × 0.62 mm width). No change.

Current Theory

I suspect the issue might be chamber or part cooling. The PET-CF may not have enough time to cool down before the last layers of the hull are laid rapidly near the 2 horizontal holes. The caving on the front and lifting at the rear could both relate to uneven cooling.

I’m wondering if anyone has fine-tuned chamber fan parameters on the H2D for PET-CF? The defaults are min 10%, max 30% (now set to min 0%). Should I try allowing a higher max fan threshold, enabling aux fan or increasing the minimum time per layer to improve layer stability ?

What’s Working Well

- Bed adhesion is strong (even at 90°C, no glue used).

- Overhangs are clean.

- Bridges are straight.

- Top surfaces look excellent.

Attached

- I’ve attached pictures of my best Benchy so far. You can clearly see the front dent and the misaligned hull lines on the upper section along with the rear side.

Thanks in advance for your input.

M

TL;DR

New to 3D printing, PET-CF giving me trouble on H2D.

Benchy with PLA = near perfect. Benchy with PET-CF = front hull dents inward, rear corner warps upward.

Tried multiple profiles, nozzle temps (270–280°C), bed temps (90–100°C), lower speeds, and confirmed flow calibration is dialed in.

Cooling or chamber fan control seems suspect.

Looking for advice on fan tuning, chamber temp, or other PET-CF-specific parameters that could reduce hull distortion.