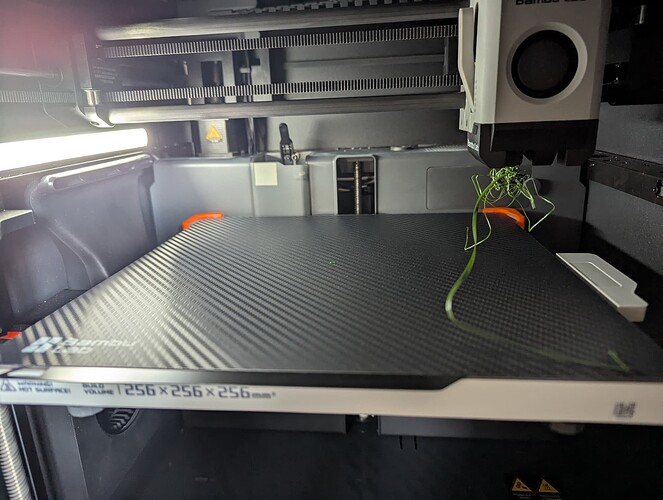

I started using PETG HF, but began to have first-layer adhesion issues too.

I dried the spool in Eibos X drier for over 12 hours, then next 12hours, washed the plate using soap, then using aceton, run the calibration, run flow and K factor calibration, increased bed temp to 80deg. Nothing helped.

It doesn’t stick to the plate, textured, smooth, or engineering.

Thanks for any advice.

Which printer?

P1S. Other PETGs are fine. PLA Basic fine too.

Just in case it is an easy one, you are keeping the door and lid closed when using this, right?

yes. With the open lid, it is slightly worse.

Using any glue stick or liquid? Or any other stickum down stuff?

Oh yes, I use glue stick. Works with all other filaments like PETG (non-HF), PLA, PETG-CF, ABS, etc.

Glue acts as a release agent for petg this could be your issue, clean your plate and try it without the glue. Also make sure what you clean your plate with doesn’t contain and moisturisers or softeners as these can have the same effect as grease and oil on the plate.

Edit: if you use IPA make sure it’s over 90% pure as under this % glycol is added to it.

I do not use glue with any filament, including:

- PLA

- PETG

- TPU

- ASA

- ABS

I have never needed it and it still confuses me why so many think it has to be used when I have not once required it.

Hello,

I’m experiencing the same issue with Bambulab PETG-HF. I’ve tried using the smooth PEI, textured PEI, and engineering plate, but the problem persists. I’m currently using the default profile provided by Bambulab. Does anyone have any suggestions on how I can fix this?

I use the bambu smooth PEI with petg hf, clean with isopropyl alcohol every third print and then some 3D Lac spray every second petg print, one small part came of in 30 prints, and some brims fixed it.

On all build plate materials?

What I’ve found is on the Cool plate PLA needs glue stick especially with small parts that don’t have much footprint and a heavy glue coat for small parts helps a lot.

With PETG HF I use the smooth PEI plate with glue stick for a bunch of solar panel netting clips I’m printing and the only failure I’ve had was in an area where the glue stick was a little thin.

I use the textured, smooth and the carbon fibre (effect) build-plates.

I have never, ever used glue on any BS printer or any others I have owned including:

- Creality CR-6 SE

- Tronxy X5SA PRO

- Tenlog TL-D3 Pro (IDEX)

I used the textured plate, printed my high tolerance fidget gyros and spinners, NO GLUE.

You can probably guess, there is a theme building.

I tested a couple things, but what did it is 80d plate (textured) and really wash it using dish soap and dish brush (not a metal one of course). And now it is perfect. I will set the build plate to go back to 70 or 75deg after first layer to avoid other issues.

No matter what I do this new PETG HF filament is very poor compared to any other PETG I’ve tried. I have used many other brands of PETG with my X1 Carbon without issue using hair spray with a copolymer component as a glue (helps it bond to plastics). This time around I decided since I had the AMS I should try and stick with Bambu filaments but I’m sorry I ordered their PETG HF. Shame on Bambu for not testing this product out fully and at least insuring it would stick as good as their previous non-NF filament. Will not be ordering Bambu PETG again… I’ll just wind another brand onto their spools.

You don’t mention if you are drying the filament. I have had wet PETG HF from Bambu right out of the shipping box and bag.

I dry my filament and PETG HF works great for me.

Forgot to mention it… I have a Creality dryer and I have dried out the PETG HF filaments per Bambu’s recommendations. It doesn’t make a difference.

I have finally be able to get the filament to stick to the Engineering plate by using Layerneer’s Original Bed Weld but this is a step backwards as far as I’m concerned. You shouldn’t have to use expensive glues to make a filament stick especially when the former version of their PETG filament didn’t have the same issues.

Thanks for your reply MZip!

Completely opposite reason for me, i’m having difficulties trying to remove the print/supports, had to do a lot of scraping to get it all removed, using the default settings set by the RFID tag

Tryed my first PETG-HF filament today and had issue with adhesion. Dryed the filament last night in sunlu 4 bay box at 70°c for 7 hours. wash and dry, than used isopropyl alcohol to clean. Used textured plate, increased first layer nozzle temp to 240 and texture plate to 75 and half the first layer speed in slice. it printed succussful. I had four failure before changing the settings. hopefully won’t have any more issue