Evening All

I’ve been using my x1 Carbon for almost a month now. Loving the quality (on the whole, but I’ll come to that) and the useability of it. I have done multiple PLA prints, using mostly the stock profiles and the speed and quality are excellent.

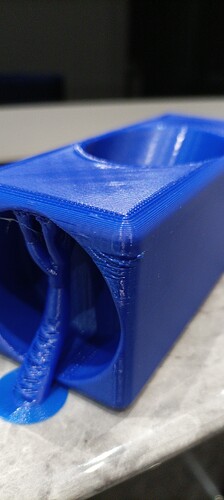

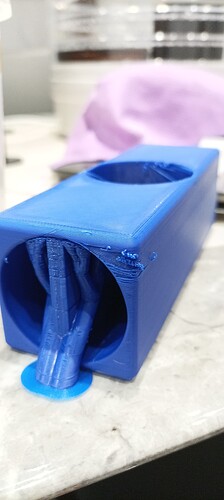

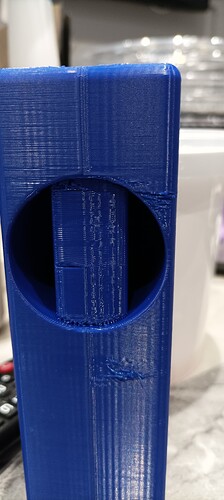

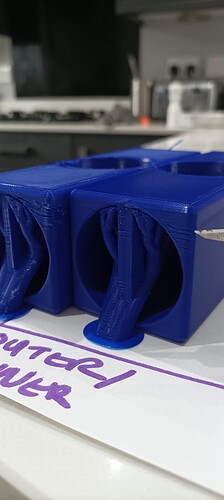

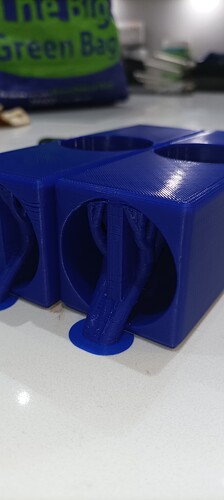

Onto my PETG prints. I’ve attached some photos of my parts, for reference, the hole you see is approximately 45mm in diameter. The parts are printed in the orientation shown. The photos are using Bambu PETG basic filament, and the stock “Extra Draft” profile. With the exception of the supports, the setup is as the profile.

I am getting what I can only describe as surface scarring. It looks as if its down to an accumulation of pickup on the nozzle, which eventually gets deposited or "ploughs through the print. In 99% of cases, it occurs at a corner, the corner you see is a radius of approx. 4mm.

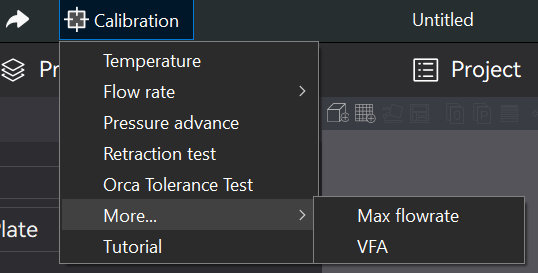

I have not done and dynamic flow calibrations for this filament (my understanding this is not required for Bambu filament).

However, this is the troubleshooting I have done so far.

- Bambu filament using the “Draft” profile (0.2mm LH): same indications.

- ESUN PETG Filament, uncalibrated using the Generic PETG profile: same indications.

- ESUN PETG using automatic dynamic calibrations (in the setting AND prior to print): same indications.

- ESUN PETG using manual dynamic calibrations: same indications.

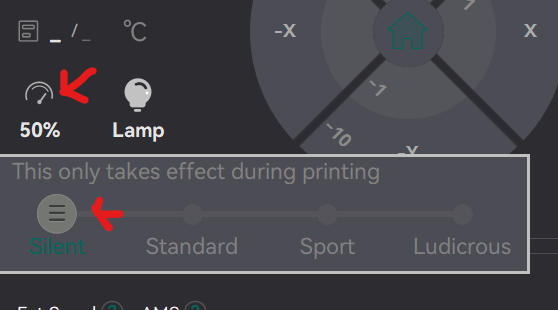

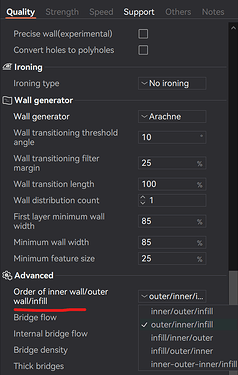

I have trawled the community, and although I have not found excactly my problem, there was a thread talking about the “Reduce Speed For Overhangs” setting causing issues. Does anyone have any experience of this?

Has anyone seen issues like this before?

I might be completely missing a trick here by not calibrating my Bambu filament - if so apologies.

Many thanks for sticking with it to the end!!!