Searching for comparative information between the two. The tough+ isn’t in the main pages data sheet yet.

They haven’t published any data yet. In the filament industry, terms like “Tough,” “High Flow (HF),” or “PLA+” are purely marketing labels - there are no standards or accepted definitions behind them. Even if a datasheet appears, don’t trust it; it will almost certainly be marketing doublespeak, not meaningful specifications.

It is available in the EU store https://store.bblcdn.eu/s8/default/f0874452d01249dba4ab6fc68ca972e4/BambuPLA_Tough_TechnicalData_Sheet_(2).pdf

Very nice, do you have the PLA cf ones too?

Yes

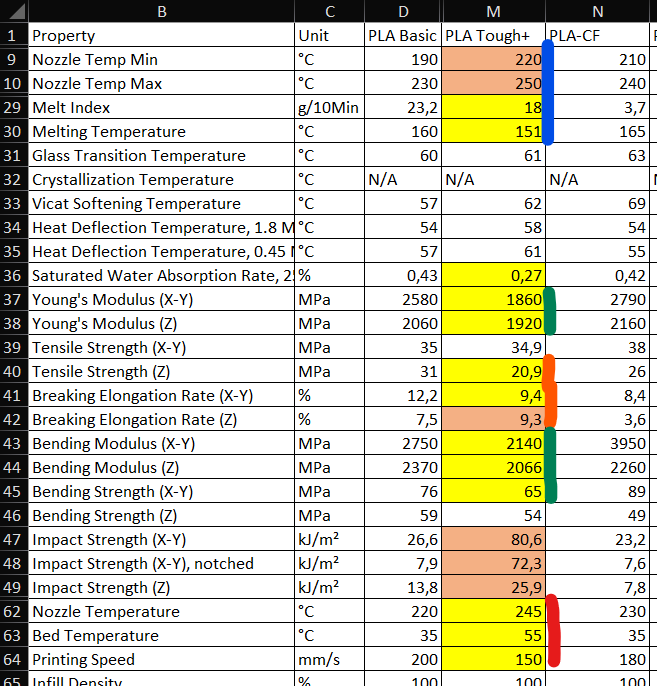

I did make a comparison chart a while ago here:

I have updated it since (except for PLA Tough) but do not seem to have posted it yet. Will do when back at my laptop.

![]() &

& ![]()

Here’s my filament TDS data. Now also with PLA Tough+.

There may be errors in it, but I hope they are few.

FDM Filament Data.3mf (287,9 KB)

FDM Filament Comparison.3mf (302,0 KB)

Since I can not upload pdf’s here, you’ll need to change the file extension back from 3mf to pdf.

![]() &

& ![]()

Thank you very much. The impact strength of the tough+ seems unbelievable. 915%

Also surprised it performs worst in most compared to straight PLA

Well, it’s what it is tailored for.

PLA is actually quite tough to beat on an individual number basis. And when trying to improve a particular property, it is quite common that other properties need to be sacrificed. Here, they seem to have succesfully traded stiffness for impact strength.

BW,

Eno

Also surprised PLA cf isn’t that much better in bending.

Tho an information missing (from my point of view) in the dataset (not your fault) is a distinction between elastic resistance and modulus vs ultimate/ plastic resistance and modulus.

Tho considering the material maybe it’s not significantly different.

Well, the C-fibres are probably not functionalized for Martix-Fibre load transfer. So they can not properly play out their stiffness. There are lower effects than the rule of mixtures would imply for the Youngs Modulus, so Bending stiffness will not be increased as much as would be expected.

That is actually the norm for TDS type documents. They are not so much intended for materials and process engineers, but written by M&P and Stress engineers for use by Designers. If Designers go into the (non-linear) plastic territory, they are overstepping their boundaries.

However, the real art is in getting the knock-down factors right. ![]() Three small words, a world of hurt when wanting to do FDM characterization for actual parts.

Three small words, a world of hurt when wanting to do FDM characterization for actual parts.

Oh, I fully understand. I did during my undergrad in civil engineering, and also during my master’s material characterisation for wood. in all direction, for generic spruce pine fir, with different screws, at different humidity level, I know the large variability material. My question was more, pla, usually, is more brittle than plastic beyond elastic maximum, but how much energy does it dissipate through plasticity (area under the curve of force-displacement / strain-elongation) basic plan, vs pla-cf vs pla tough+ in the sense of what is the main gain of the cf (and by extension justification for the price)

A very good question. And one for which I am missing a lot of chemical fundamentals on one hand ![]() , and of course, we unfortunately do not have the modulus in the plastic region.

, and of course, we unfortunately do not have the modulus in the plastic region.

In addition, we need to keep in mind that the development goal must have been much more than pure material tailoring. They must have focused on layer adhesion, i.e. the fusion of the layers. Trading inherent pure properties with processed material properties. That is quite an achievement in itself.

While my missing chemical competence does not allow me to make educated guesses, there is some stuff we can gleam from the data.

- Despite a lower melting temperature, the printing temperature is quite a bit higher (blue).

- The printed material (in-plane) was softened significantly (green). However, I was quite surprised about the reduction of the in-plane strain to failure while raising z-strain to the same level (orange).

- This is easy to misinterpretate: Test specimen printing conditions have much higher printing temps at a lower speed (red).

So wether it was the addition of a softer, lower melting polymer or additives to achieve the same effect (or a combination of both), … I am unfortunately missing the chemical basics to speculate on that. But it is clear that some tailored chemical engineering was conducted which would merit a price difference.

The PLA-CF is mainly of interest for thermal and surface/optical properties. So it is not really competing with the PLA Tough+. If a design requires particular key properties, we usually need to look at the full range of materials and compare them to the application.

BW,

Eno