Once the print reached the final support layers, the top layers have poor infill.

Thank you for any help.

We have not much information on you settings or filaments being used.

Lets hope your nozzle is not clogged.

If I take a guess you are using black pla with support W ?

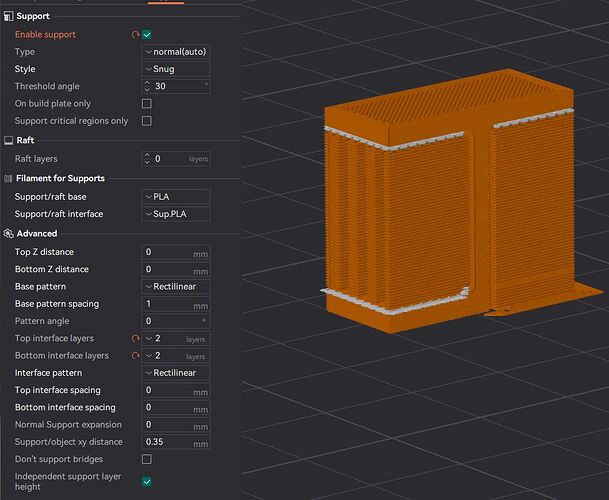

You can give this a go and set your supports up like this or post more information.

keep us updated ![]()

Thank you for your response.

I am obviously new at this. I am using the PLA-CF and PLA support.

I had Support/raft base = Support. I notice you use PLA. Why not use support?

Style = default

My original file was a Step file. After further research, I noticed Bambu prefers 3MF files. Do you think this makes a difference?

Thank you for your help.

Dr. D.

Hello Dr. D.

Do to I did not know what filaments you was using the sample above was if your part was just a basic pla and we would use basic pla as the support base then use a pva or breakaway support for the interface layers this would allow less filament changes and the part will print way faster and save filament so look at your slice times and you will see what I’m talking about.

The 3mf file will have more information.

This is why they prefer 3mf files and this file type was made for 3d printer but the other file types are ok to use most people are using step or stl files but if you have a choice then ya use the better one.

Think of it like vhs vs hd-tv ![]()

Style = default = This Link will show you why and when to pick your filament.

Being you are new to 3D printing, test out with basic pla and support combos use the cheap stuff save your carbon fiber filament until you have some good working settings.

Tip: With pla carbon fiber filament don’t go lower than 0.15 layer height or you will get under extrusions with a .4 nozzle.

We would need more information on your pla-cf settings used.

Happy 3D Printing ![]()

STEP files are much better than 3mf files, which Studio uses as project files.

3MF files include the mesh/triangle representation of the model just like an STL file.

A step file is an actual solid model that has accurate information.

Just imagine a round rod. With the STEP file the length and circumference are known. With a mesh, you have many triangles that approximate the surface of the rod, and accuracy depends on the number of triangles, but it is never truly accurate because there are no curved lines.

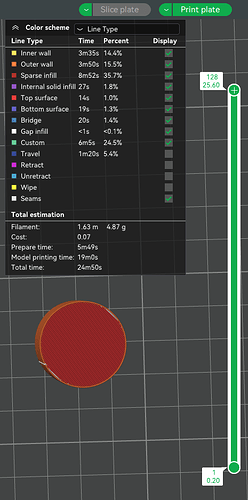

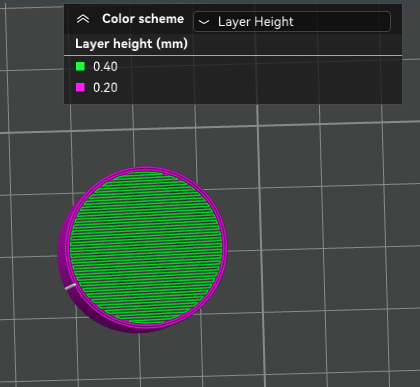

In the preview mode in the slicer use the slider on the right to move to show different layers. You can use the down arrow and it will go down 1 layer at a time.

The preview starts at the top layer. (Use 1 to change to a top down view.)

you are looking at the final top layer. Top surface is shown in red.

Now down arrow. You are now seeing the purple solid inner fill.

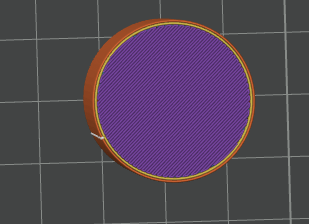

down again and you are seeing the bridging over the infill in blue

down again and you can see the infill pattern.

now I go back up one layer and I am looking at the bridging, but with line height selected. What you see is that the bridging line height is double the normal layer height. If you have a high density infill the layer will be too thick and cause problems for the following two layers. Normally with 15% infill and most infill patterns the double thick bridge just provides a good surface for the following layers. It just “settles down” into the infill and is effectively a normal .2mm layer.

Thank you.

I will use PLA tough and PLA Basic like you suggested.

I had a clogged nozzle with the PLA CF. What do you think about changing to a 0.6mm nozzle when using PLA CF?

Thank you.

Dr. D.

Yes .6 nozzle will help with any carbon fiber filaments.

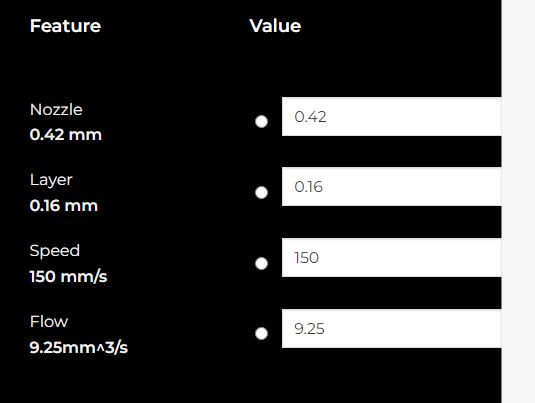

You can use pla or petg carbon fiber with the .4 nozzle just don’t go below 0.15 layer height and don’t print at high speeds you can lower your volumetric max speed set it to 9.25 with the .4 nozzle and see how it works out this will help keep the speed cap @ 150 mm/s max.

I don’t use the Bambu Lab pla-cf or I could give you the speed settings needed but I do print other types of carbon fiber filaments.