I have trouble printing a bellows from TPU 95A. It prints great at first but at some point, it begins to lay every second loop wrong. Filament loops fall down:

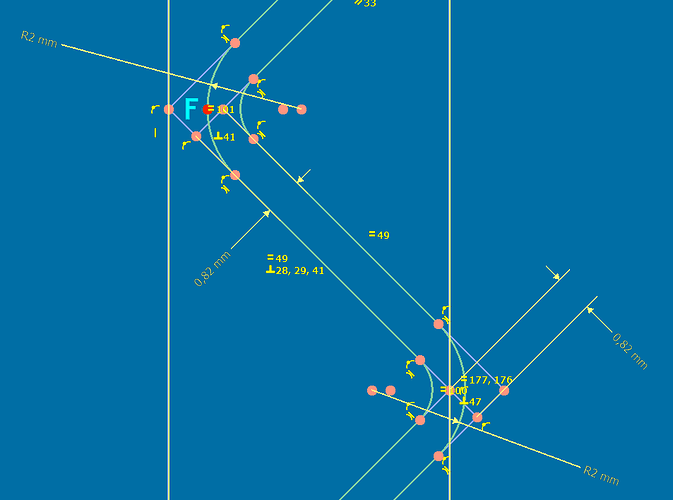

The problem begins/end in the seam area, were the loops around the perimeter begin/end. However, while I see a one seam in Bambu Studio, in reality the problem begins a bit before and a bit after the seam. Also, the seam in the software is a straight line, but the problem areas in the print are arranged in a “V” (seam right in the middle)?!

Strength 0.2mm. Angle of the folds 45°. Wall thickness 0.82mm in straight parts, 0.7mm in chamfered parts (F in picture; to make the bellows less stiff).

I use the classic wall generator. It leads to 3 wall loops in straight parts, 2 in chamfered parts.

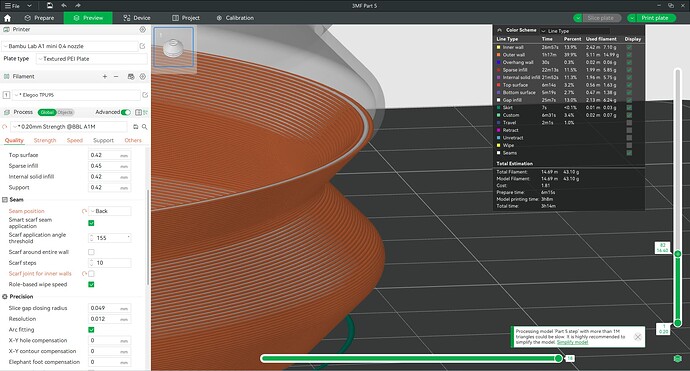

I print Elegoo TPU95A at 55mm/s, 225°C, 0,4mm nozzle. I use the Bambu TPU 95 preset with small changes (lowered cooling from 100% to 75%).