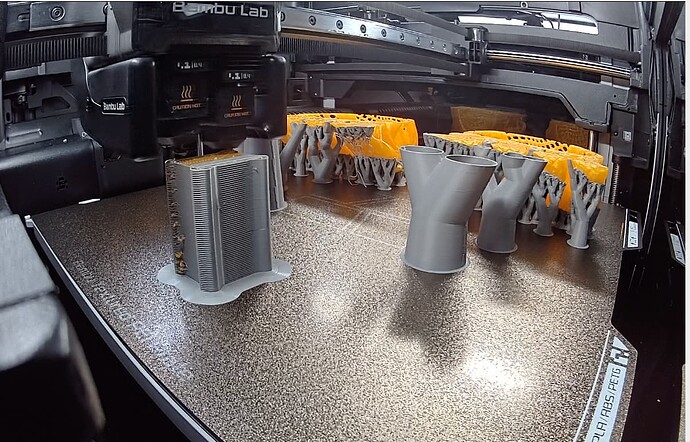

So I’m printing a pair of Whaleberries (3D printed shoes) which have a 5 day printing time on my stock 0.4 nozzles. I’ve heard people say using 0.6 nozzle is preferable with TPU. I was curious if anyone had any experience with this. Also curious if anybody has used the high flow nozzles. I just ordered a pair… (the 0.6 are sold out until June so not an option at this point)

It all depends on the hardness of the TPU shore rating.

The challenge when using very soft TPU lies in the extruder. A larger nozzle helps reduce back pressure, making it easier for the extruder to push the filament through. Too much back pressure can cause the extruder to grind the TPU filament, leading to print failure.

That’s why it’s better to use a 0.6 mm nozzle when printing with materials like TPU 85A, or even larger if you’re working with something softer, like TPU 60A.

So I sliced the model with three different nozzle sizes. This was unexpected. I guess it must relate to TPU’s slow printing speed. I guess…

| Nozzle | Layer Height | Time | ||

|---|---|---|---|---|

| days | hous | minutes | ||

| 0.4 | 0.2 | 4 | 9 | 6 |

| 0.4 HF | 0.2 | 4 | 9 | 1 |

| 0.6 | 0.3 | 4 | 23 | 59 |

For unknown reasons, BL doesn’t have profiles that reduce the print time when larger nozzle sizes are used.

This is true with PLA and TPU.

With older printers I had, print times drastically reduced when larger nozzles and corresponding layer heights increased.

What I’ve noticed helps is if you use 2 loops instead of 3 etc. I mostly use 3 loops with a 0.4mm nozzle for functional parts. With a 0.6mm nozzle I will use 2 loops. So it does speed it up in this scenario. I feel Bambu just hasn’t invested any time in 0.2, 0.6, 0.8mm nozzle profiles. I’m assuming they might if they finally release a 0.6mm HF nozzle. Not sure how much flow dynamics will play into this as a 0.4mm HF maxes out a lot of filaments already.

2 loops? I’m sorry, what does this mean? Wall loops? I’m using 2 for the shoes.

Yes, walloops, I know it may not help you in this print. I was just explaining what other types of prints that having a 0.6mm nozzle does seem to help with. Two wall loops with a 0.6mm nozzle is wider than 3 and almost the same as 4 wall loops with a 0.4mm nozzle.

It’s the same for PLA as for TPU, 0.6er or 0.8er nozzle does not really make a benefit. I am just using these nozzles if the filament requires it. But 0.4 is the sweet spot, there is no doubt. Unfortunately…