When printing with stiff fiber reinforced filaments that need to go through the bypass port, it turns out you can print and dry simultaneously. And if you are willing to drill a small extra hole for an auxiliary bypass port in front of the cover of the AMS HT, there are a bunch of benefits besides just drying while printing:

- The filament is way easier to load through the bypass port

- The heated filament will be slightly more flexible and feed more easily through all the tubing

- The periodic rotation of the spool will reduce the tendency for the spool to get cocked and jam. (I’ve been having terrible jamming problems when running PPA-CF out the standard bypass port.)

Note: I wouldn’t recommend this for anything but stiff fiber filled filaments because the heated filament may become too soft for the extruder feeder.

More details below the photos.

Basic Drying While Printing

First feed your filament out through the bypass port and load the filament as if it were coming from the external spool. Then start your drying cycle. If you are using the standard bypass port, do not use the “rotate spool” option because it rotates the spool in the wrong direction. Then just start your print specifying the external spool as the filament source. If you have turned on the spool rotation, make sure to stop the dry cycle shortly after printing or you will end up with an unspooled mess inside the AMS HT!

Creating an Auxiliary Front Bypass Port

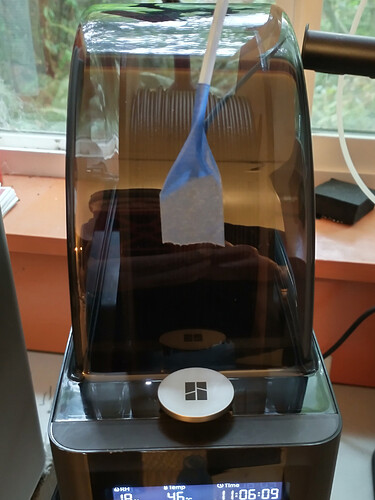

The reason you need to create a front bypass port is because the default spool rotation direction used for drying is backwards from what you would need for feeding. The solution is to flip the spool over, but then the exit path of the filament is all wrong for the stock bypass port hole and grommet. I solved this by drilling a 4mm diameter hole in the front of the AMS HT cover as shown in the photo. After starting the drill perpendicular to the surface, I angled the drill bit downward so that with the feed tube inserted, it can angle down nicely towards the perimeter of the spool. The cover appears to be polycarbonate which drilled nicely without cracking.

To seal the hole around the feed tub and also hold the feed tube in place, I just used some blue painters tape to tape the tube to the cover as shown. (What seasoned 3D printing nerd doesn’t still have some of that lying around?) When not using the auxiliary bypass port, you can just put a little patch of tape over the hole. At some point, I may try designing a TPU grommet to cover the hole and hold the tube, but the tape is really quick and easy to use.