Hi Bambu Collective.

I’ve been printing accurate dimensional prints for a while now, but suddenly, nothing is dimensionally correct anymore. I’ve made no changes to settings in the file and no software/firmware updates.

Corners bulge out, edges bow in, nothing aligns or fits.

I’m running Bambu studio 1.9.3.5 (because I was told not to update) for X1C, not sure what firmware version on the printer itself but also haven’t updated when prompted. Printing on a textured plate with PLA that is the same roll in all the photos. (printing on a textured plate because I can’t get filament to stick to the smooth one anymore).

.4 nozzle

I did a recalibrate and it slightly fixed the issue but definitely didn’t solve it. Maintenance was done; lead screws and greased the carbon rods.

Nothing has changed. The only thing I think of that may have changed between the good print and the bad was I did a print-in-place magnet, but the magnet never came in contact with the hotend, even though it came close.

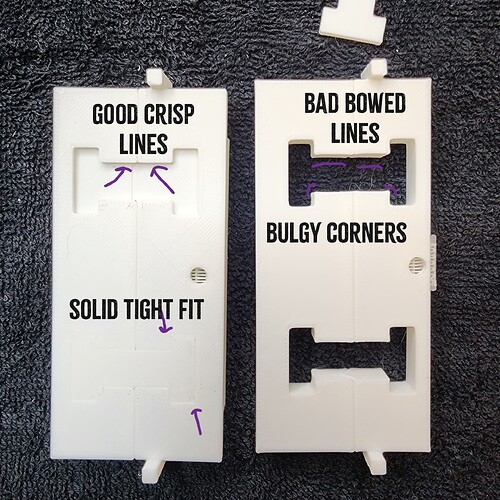

Image on the left is the Good print that came out perfectly, the inserts click into place so tight you can barely see them. The image on the left is the Bad print that was after making a slight adjustment to the model for the I beam insert to go all the way through, the edges are so bowed and the corners all bulgy that I couldn’t get the insert (which also was all bulgy and bowed) to even remotely fit in)

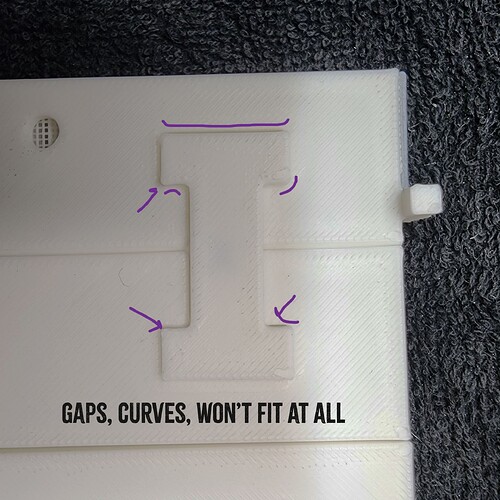

Really tough to photograph but there is basically gaps all around because nothing is aligning anymore

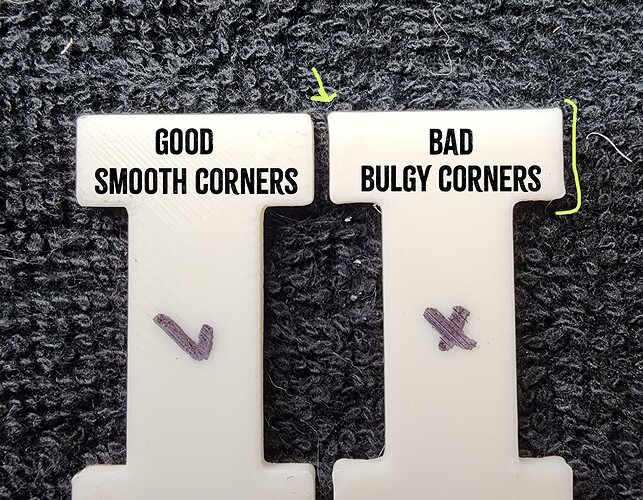

Inserts up close, good on the left, bad on the right; bulgy corners, curved edges.

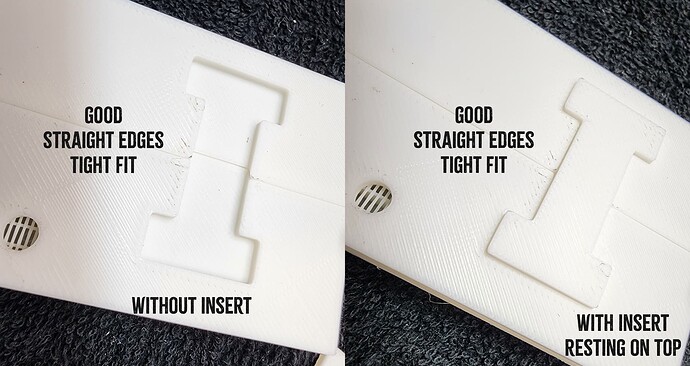

the Good print of how it’s supposed to all look; nice crisp straight edges, smooth surface layer.

Even the surface layers look all weird and misaligned.

The printer has been an absolute gem up until now! Any ideas what could be the issue? I don’t want to go buying a new hotend or other supplies if that’s not the issue. Especially, if someone has a better idea or has gone through this already.

Thanks in advance.

-J