@edsped

Each printer has its purpose.

-The ratrig covers giant stuff. Youd be amazed how often I need something just slightly bigger than 350mm. One piece risers, replica wheels. Fun stuff like that. But its huge and makes noise.

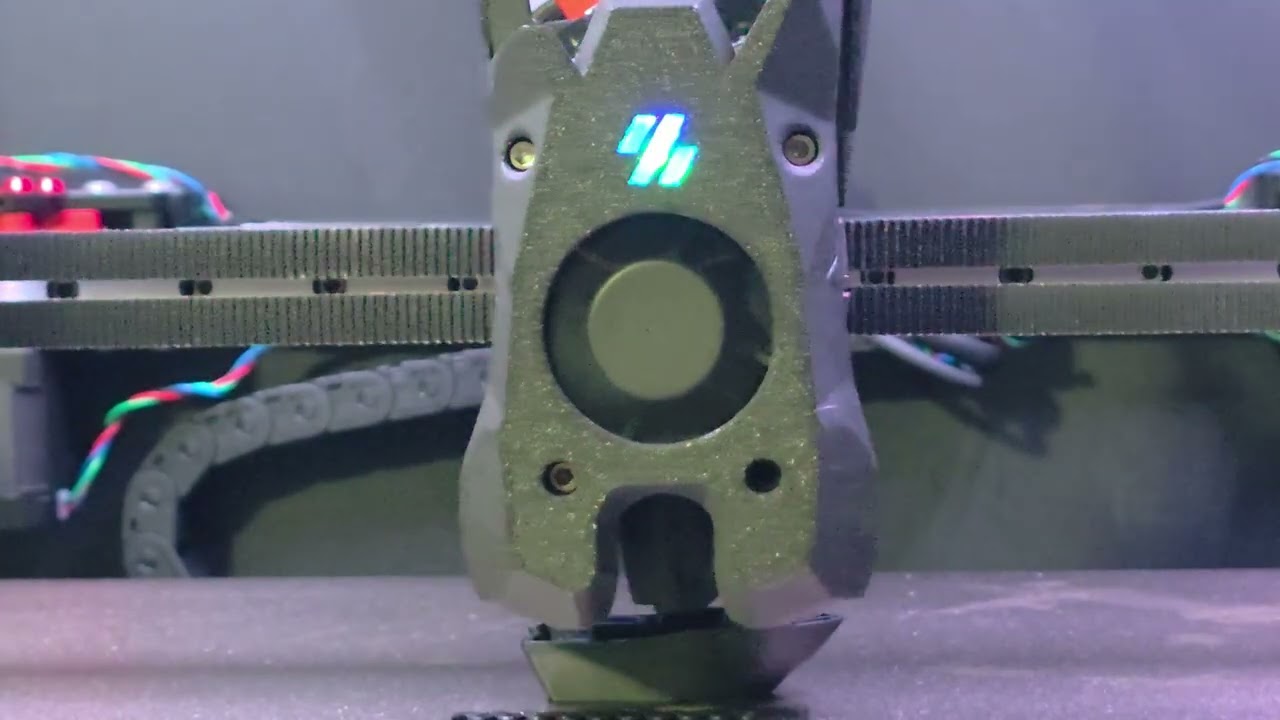

-Vorons are limitless in what they can do. Ever wish you printer could do something? Be any size you want, multihead, idex, have an ams, heated to whatever temp you want, print any material. Its all possible. And the community(same as ratrig) are the nicest and smartest people you will ever meet. Most of them could build a legit robot, if they wanted. But the voron is almost always in the process of being modified. Hardware or software.

-Bambus are easy. My go to for the majority of things, but they cant do everything and they arent very “fun”, once youve printed all the toys. They are a tool and about as fun as a wrench or hammer. H2D for everything that wont fit in the X1C

-My XL is large and a money saver that can do multicolor tpu or whatever I throw at it. Not the best for engineering material though. Also not as easy as other printers.

-Other printers I buy/test/give away or sell, is just to experience as many types of printers as possible. I love it so much.

Just spent the last 3 weekends modifying my voron and I used the h2d to make the parts. 400 point bed scan at the end

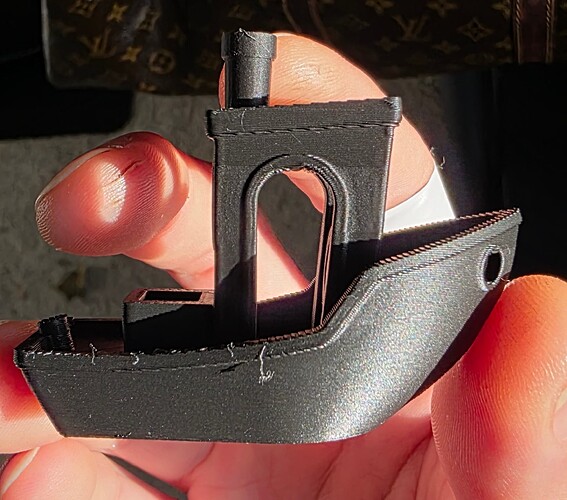

First print after changing parts

Bambu should let us run our own input shaper tests, view the graphs and set our own frequency. The auto stuff does a decent job, but something like klipper shake tune is better imo.

500mm ratrig 21 minute benchy. Bambu charcoal PLA This is whats possible.